Capacitor motor and process for producing the same

A manufacturing method and motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increased winding loss, reduced motor efficiency, and longer circumference, so as to reduce the magnetic flux density and improve the efficiency of the motor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

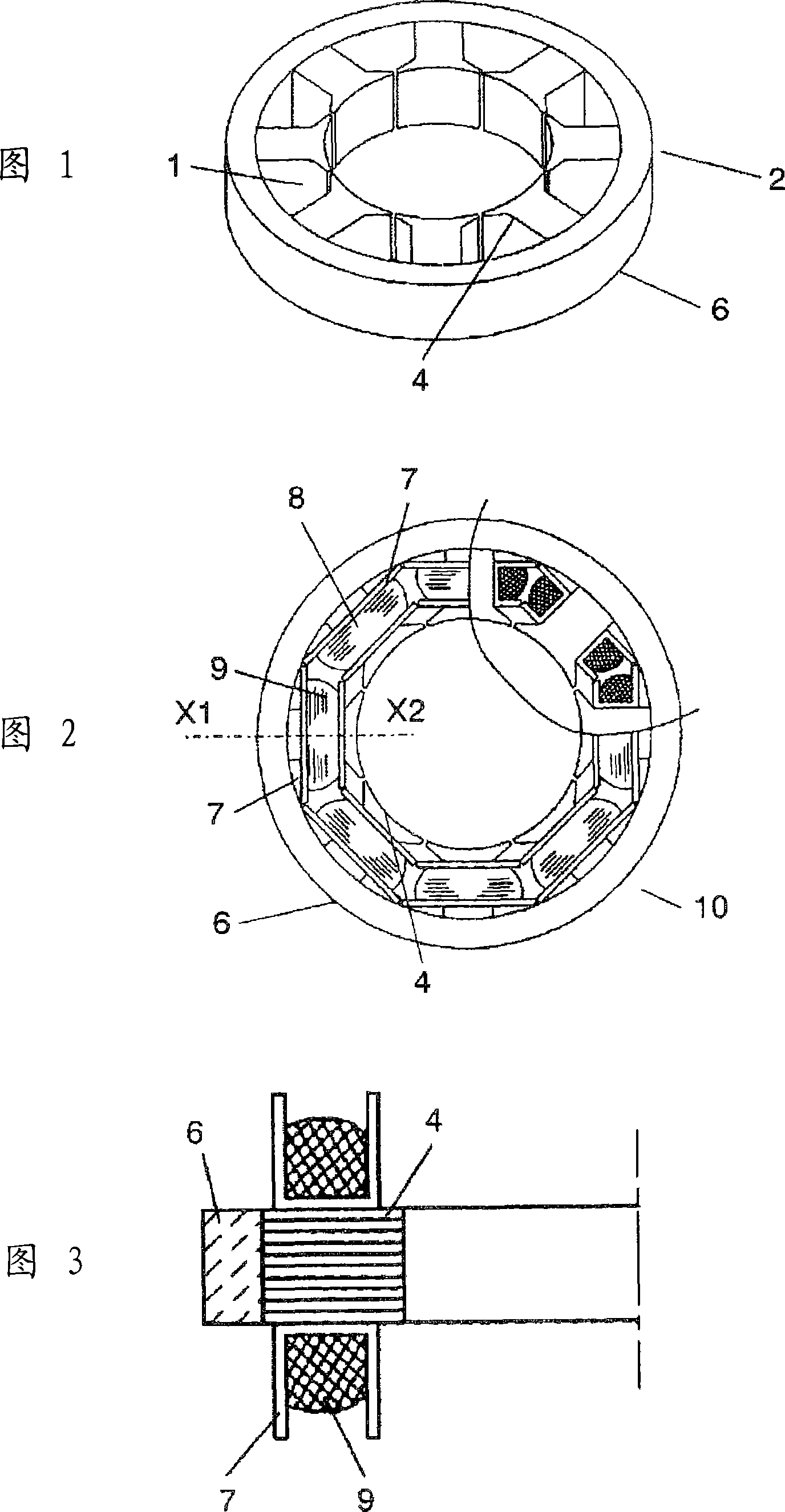

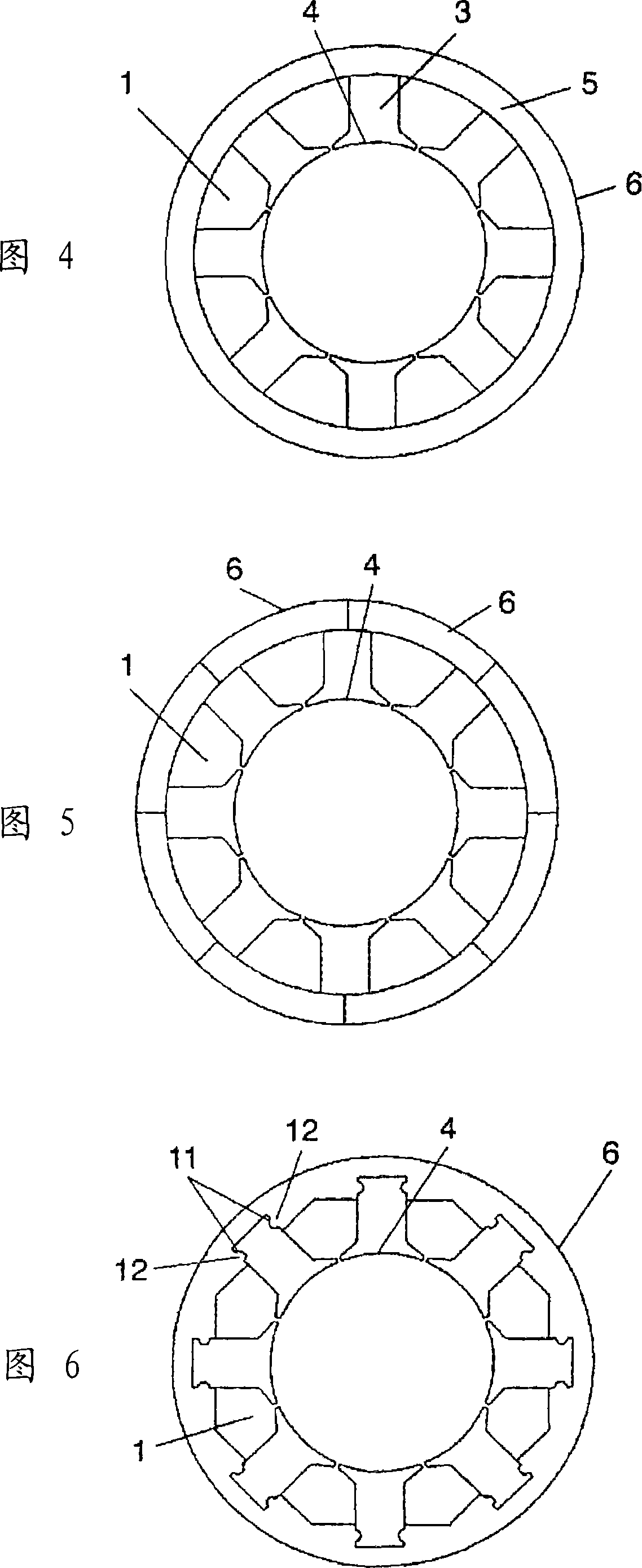

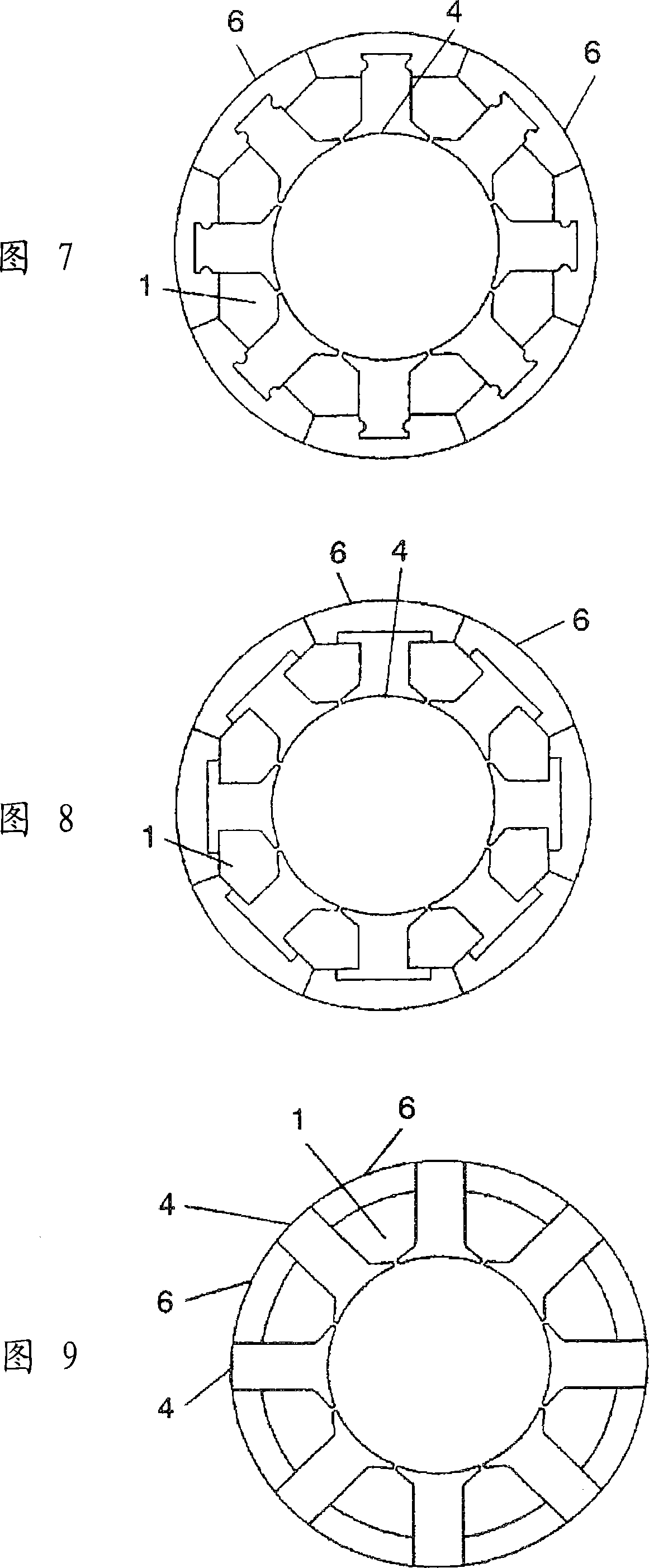

[0076] 1 to 10 show a stator of a capacitor motor according to this embodiment. As shown in these figures, the configuration of the capacitor motor of the present invention is that the stator core 2 having eight slots 1 is divided into eight first split iron core bodies 4 and second split iron core bodies 6, wherein the first split iron core body 6 One split iron core body 4 mainly forms each tooth portion 3; the second split iron core body 6 forms a magnetic circuit as a yoke portion on the outer peripheral side of the first split iron core body 4 and the slot 1. Each first split iron core body 4 is formed by punching and laminating electromagnetic steel sheets, and A-phase winding 8 or B-phase winding 9 wound on insulating bobbin 7 is attached to each tooth portion 3 . The first split iron core bodies 4 on which the A-phase winding 8 is attached and the first split iron core bodies 4 on which the B-phase winding 9 is attached are arranged alternately and annularly. The seco...

Embodiment approach 2

[0085] A second embodiment will be described based on FIGS. 11 to 13 . The same symbols are used for the same structural elements as those in Embodiment 1, and descriptions thereof are omitted.

[0086] In Fig. 11 and Fig. 12, the difference from Embodiment 1 is that the thickness N in the axial direction of the second split iron core body 6A formed by molding magnetic powder into a dust core of a predetermined shape is set to be smaller than that of punching and layering. The axial thickness L of the tooth portion 3 of the first split iron core body 4 of the laminated electrical steel plate, that is, the portion where the winding is mounted or wound is long. In addition, a rotor 14 having a rotor core 13 is arranged on the inner diameter portion of the stator core 2. The rotor core 13 is coaxial with the stator core 2 and is held to be freely rotatable. Its dimension M is the same as that of the first split core body The axial thickness L of 6A is the same.

[0087] In the ...

Embodiment approach 3

[0091] A third embodiment will be described with reference to FIGS. 14 and 15 . The same symbols are used for the same constituent elements as in Embodiments 1 and 2, and descriptions thereof are omitted.

[0092] As shown in FIGS. 14 and 15 , the difference from Embodiments 1 and 2 is the thickness in the axial direction of the second split iron core body 6A formed by molding magnetic powder into a dust core of a predetermined shape in Embodiment 2. , it is set to be longer than the axial thickness of the tooth part 3 of the first split iron core body 4 of the punched and laminated electromagnetic steel plate, that is, the part where the winding is installed or wound, and the following structural features are added on top of it, that is: for each second On the inside of the axial surface on the outer peripheral side of the split iron core body 4, on the inside of the axial surface of the front end portion on the same inner peripheral side, etc., the portion where the winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com