Vertical type bubbling oxidation reaction device for synthesizing naphthalic acid

An oxidation reaction, naphthalene dicarboxylic acid technology, applied in chemical/physical/physical chemistry fixed reactor, preparation of organic compounds, organic chemistry, etc., can solve the problems of high maintenance cost, high energy consumption, complex equipment, etc. Reliable work, improved yield and purity, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

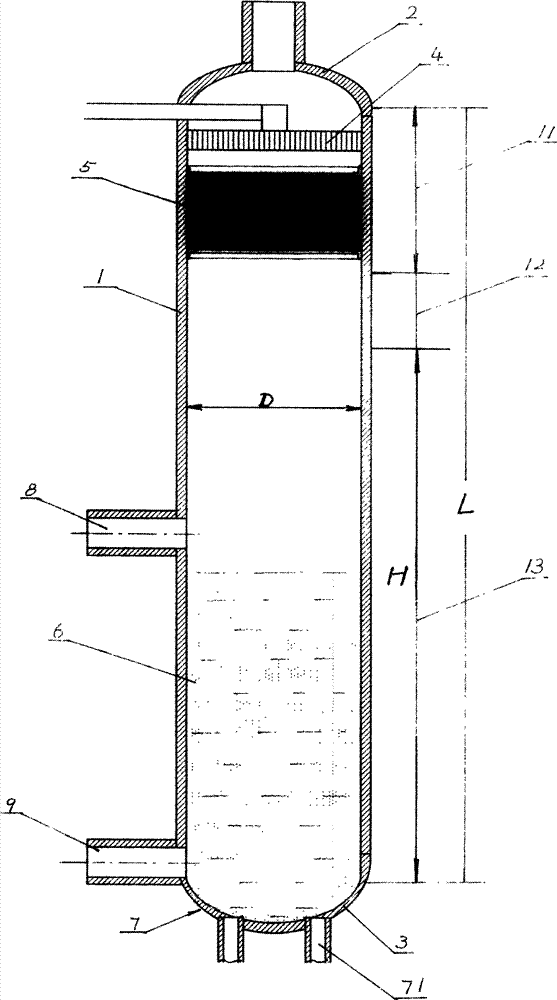

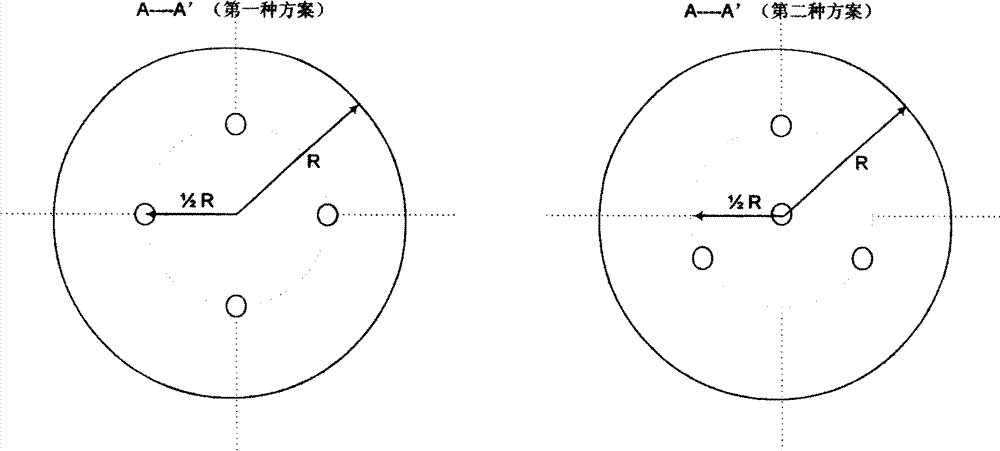

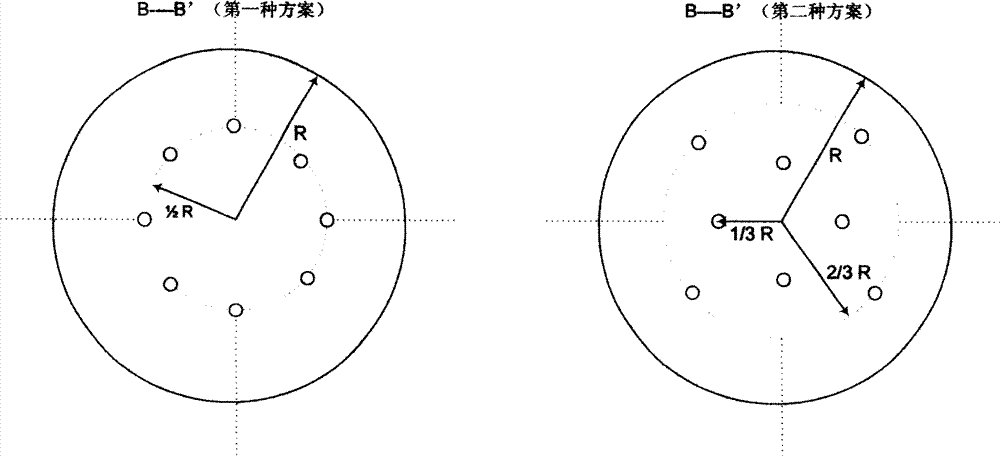

[0013] Depend on figure 1 As shown, a vertical bubbling oxidation reaction device for synthesizing naphthalene dicarboxylic acid is mainly composed of a straight cylinder body 1, a top cover 2, a bottom cover 3, a liquid distributor 4, a structured packing 5, a reaction liquid 6, and a gas distributor 7 , feed port 8 and discharge port 9, wherein: the straight cylinder body 1 is a straight cylinder structure with a length of L and an inner wall diameter of D, and the length L of the straight cylinder body 1 should include the length of the rectifying section 11 required for the oxidation reaction , the length of free section 12 and the length H of reaction section 13, the length H of its reaction section 13 should be (60~90)% of straight cylinder body 1 length L, preferably (70~80)%, and H / D= 2~8; The length of the free section 12 between the rectifying section 11 and the reaction section 13 should be (10~20)% of the length L of the straight cylinder body 1; The location of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com