Non-leakage flat gate valve

A flat gate valve, no leakage technology, applied in the field of gate valve sealing structure, can solve the problems of difficult valve seat processing, poor sealing performance between valve seat and valve plate, inconvenient measurement, etc., to achieve improved sealing effect, high manufacturing precision, Ease of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

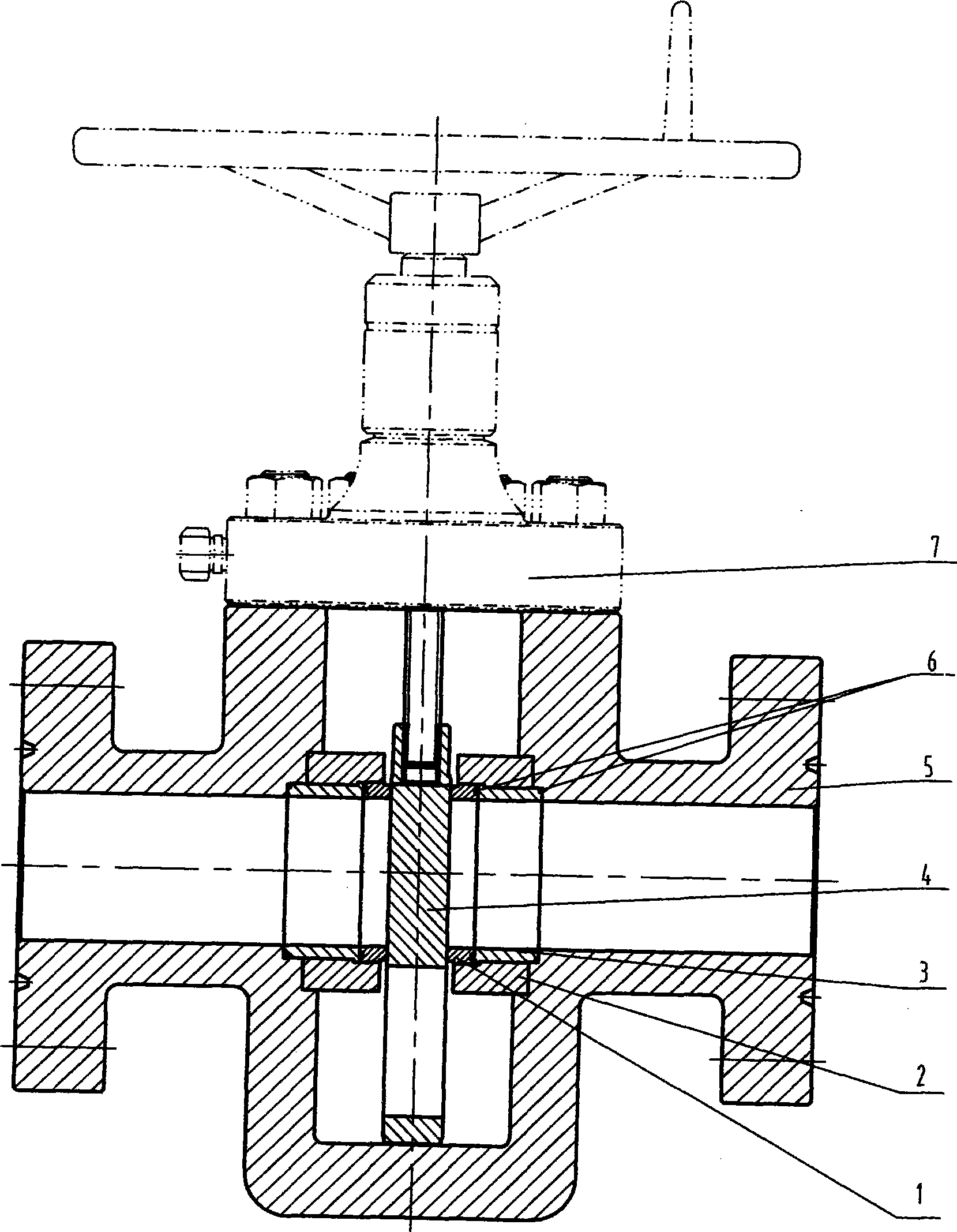

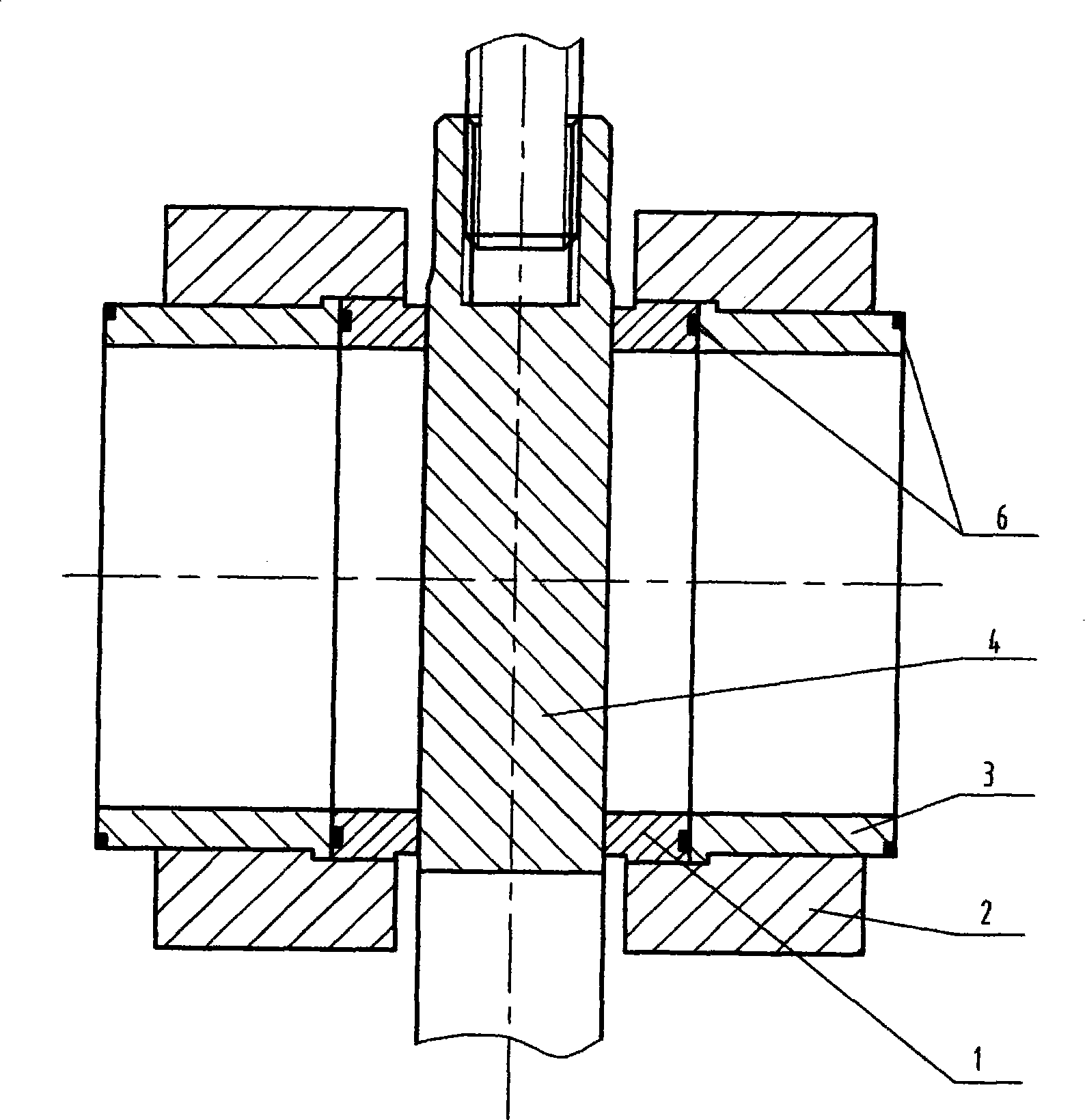

[0015] figure 1 The non-leakage slab gate valve shown includes a valve seat 1, a positioning sleeve 2, a core sleeve 3, a valve plate 4, a valve body 5, a sealing ring 6 and a gate valve adjustment mechanism 7. The valve plate 4 is a rectangular plate of equal thickness, its upper end is connected with the screw rod of the gate valve adjustment mechanism, the middle part is solid or has a dark rod lifting thread, and the lower part is provided with a through hole with the same size as the inner hole of the valve seat 1. The valve plate 4 It is tightly matched with the end faces of the valve seat 1 on the left and right sides. The valve seat 1 is installed in the inner cavity of the valve body 5 through the positioning sleeve 2. The core sleeve 3 and the valve seat 1 are coaxial and the core sleeve 3 and the positioning sleeve 1 are in clearance fit. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com