Electrophotographic photoreceptor and electrophotographic imaging apparatus employing the same

An electrophotographic and imaging device technology, applied in the field of electrophotographic imaging devices and electrophotographic photoreceptors, to achieve the effects of high-quality images, high image quality and stability, and low residual potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

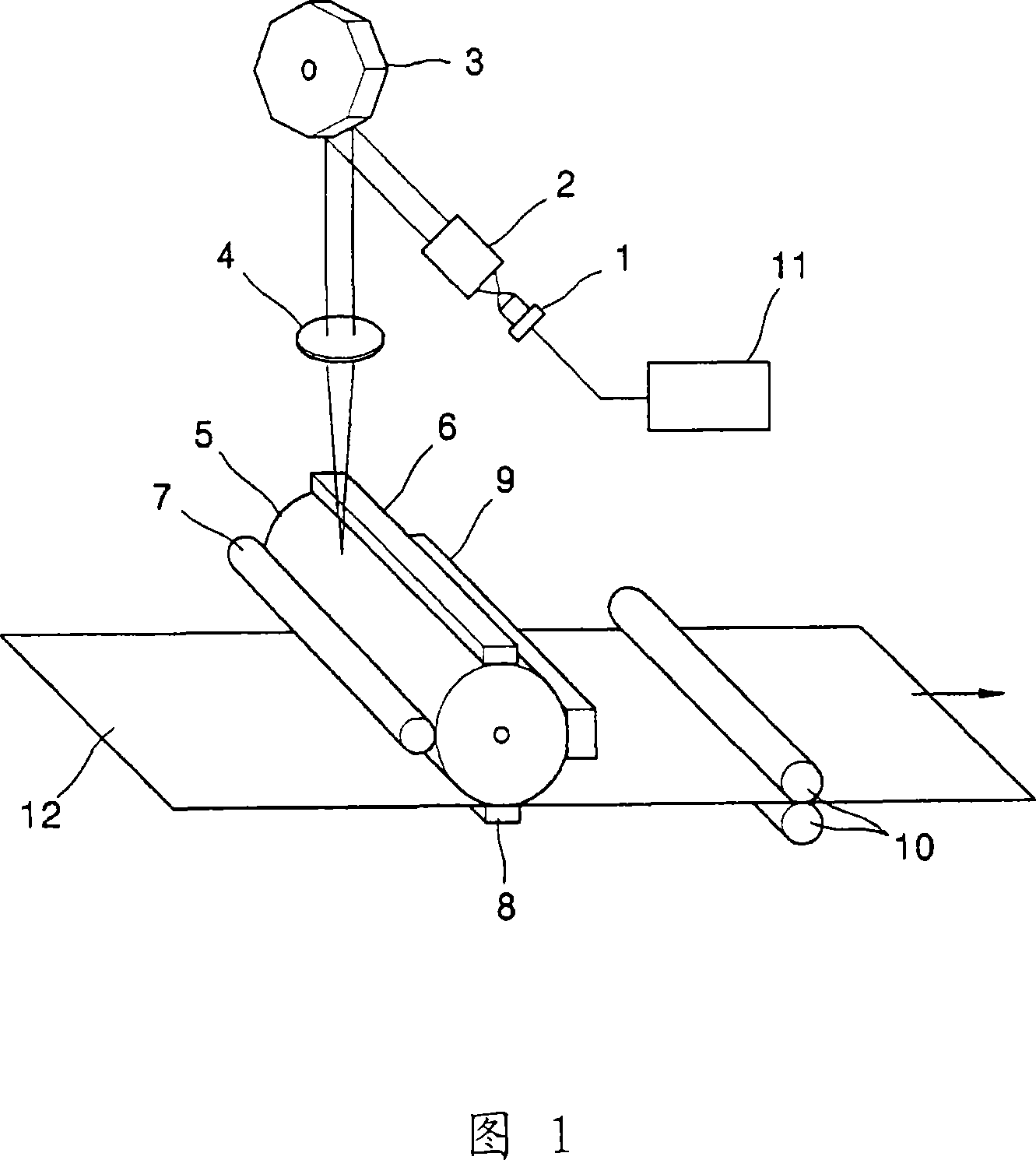

Image

Examples

Embodiment 1

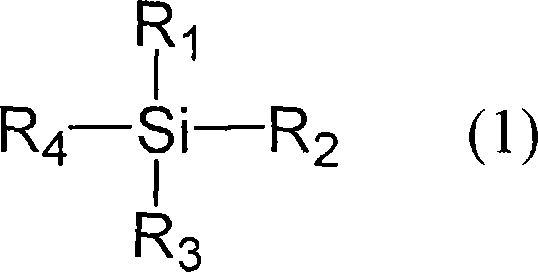

[0087] 4000 parts by weight of alumina balls (5 mmΦ), 160 parts by weight of titanium oxide (TTO-55N manufactured by Ishihara Industries, Co., with an average primary diameter of about 35 nm) and 4 parts by weight of dimethyldimethoxysilane were added to 320 parts by weight of methanol and dispersed by ball milling for 20 hours. The obtained dispersion was diluted with 1120 parts by weight of methanol, and the diluted dispersion was added to a solution of 80 parts by weight of nylon resin (CM 8000 manufactured by Toray Industries, Co.) dissolved in 320 parts by weight of methanol, and homogenized to obtain Coating composition for undercoating. The coating composition for an undercoat layer was coated on an aluminum drum having an outer diameter of 24 mmΦ, a length of 236 mm, and a thickness of 1 mm and dried in an oven at 100° C. for 30 minutes to form an undercoat layer having a thickness of 1 to 5 μm.

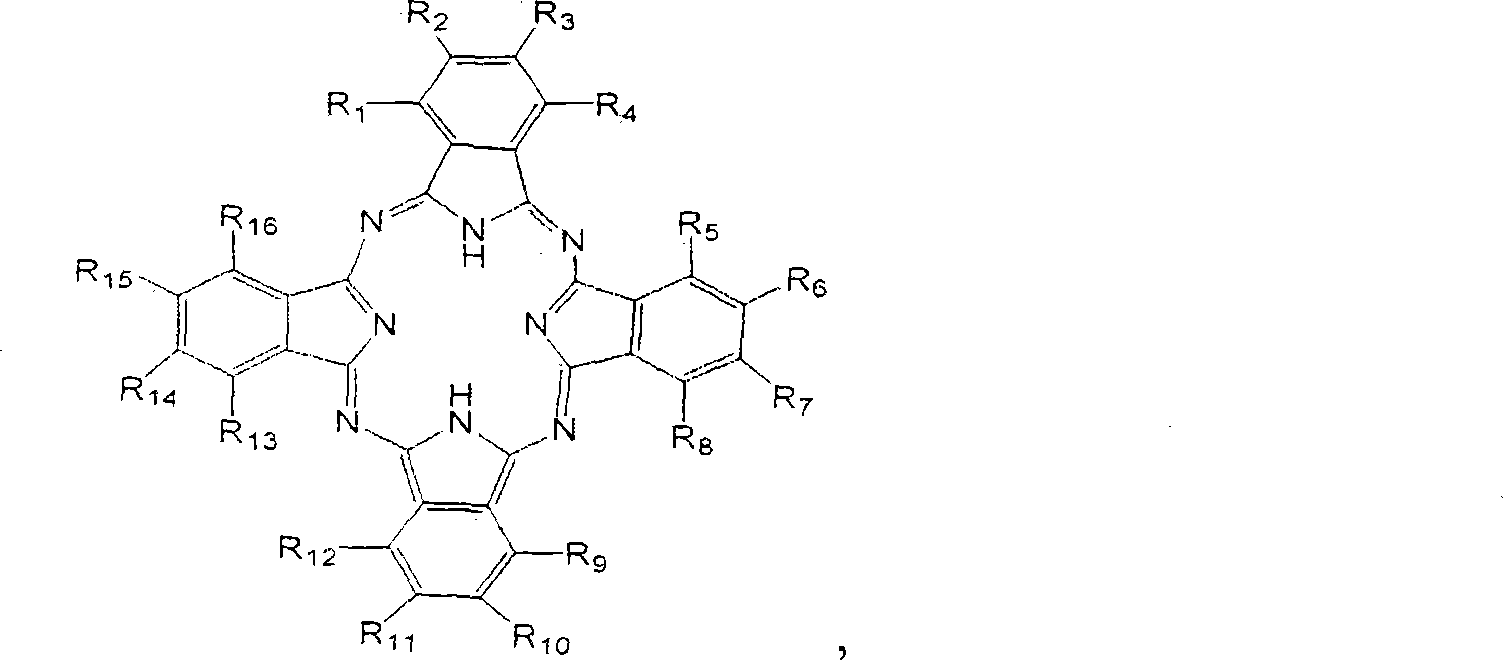

[0088] 5 parts by weight of γ-type oxytitanium phthalocyanine, 2.5 part...

Embodiment 2

[0091] A laminated photoreceptor drum was prepared in the same manner as in Example 1, except that 4 parts by weight of phenyltrimethoxysilane was used instead of 4 parts by weight of dimethyldimethoxysilane to prepare a coating composition for an undercoat layer .

Embodiment 3

[0093] A laminated photoreceptor drum was prepared in the same manner as in Example 1, except that 4 parts by weight of trimethoxypropylsilane was used instead of 4 parts by weight of dimethyldimethoxysilane to prepare a coating composition for an undercoat layer .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com