Brushless ac excitation speed-changing same-frequency generator

An AC excitation and generator technology, applied in synchronous generators, control generators, synchronous machines, etc., can solve the problems of increased maintenance and operating costs of generators, complex inverter structures, shortened service life, etc. Network automatic control device, eliminating the frequency conversion device and speed-up device, the effect of reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

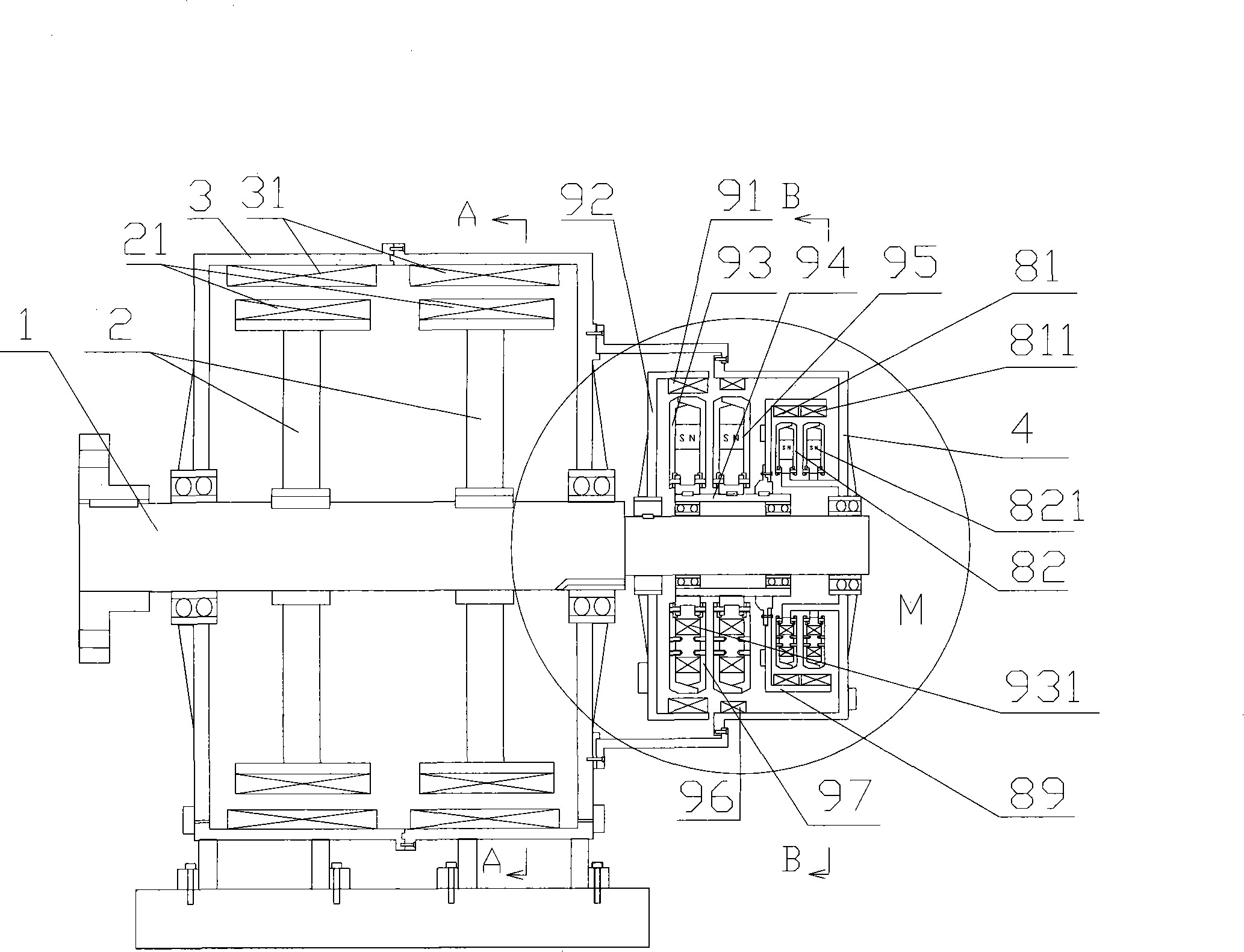

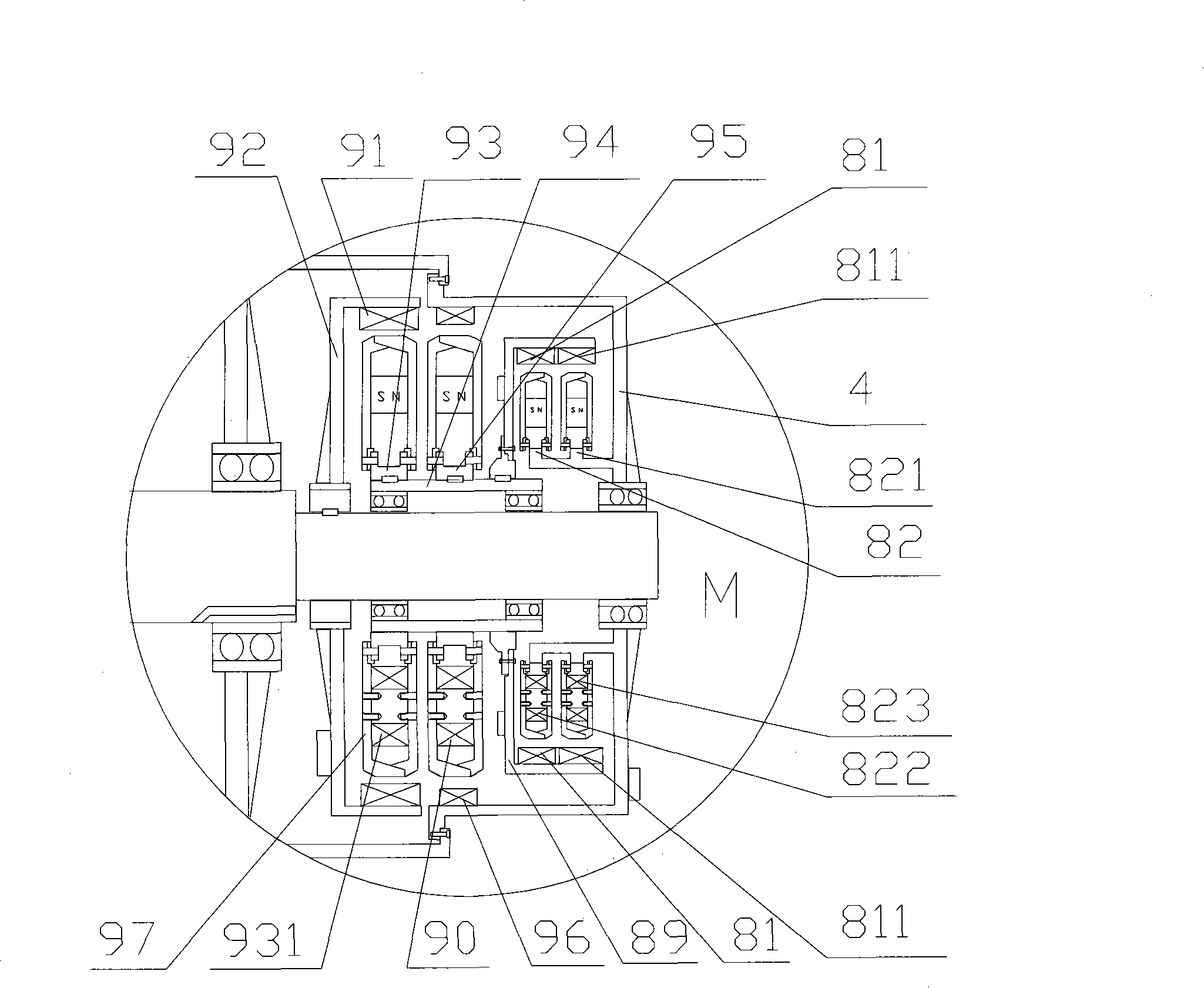

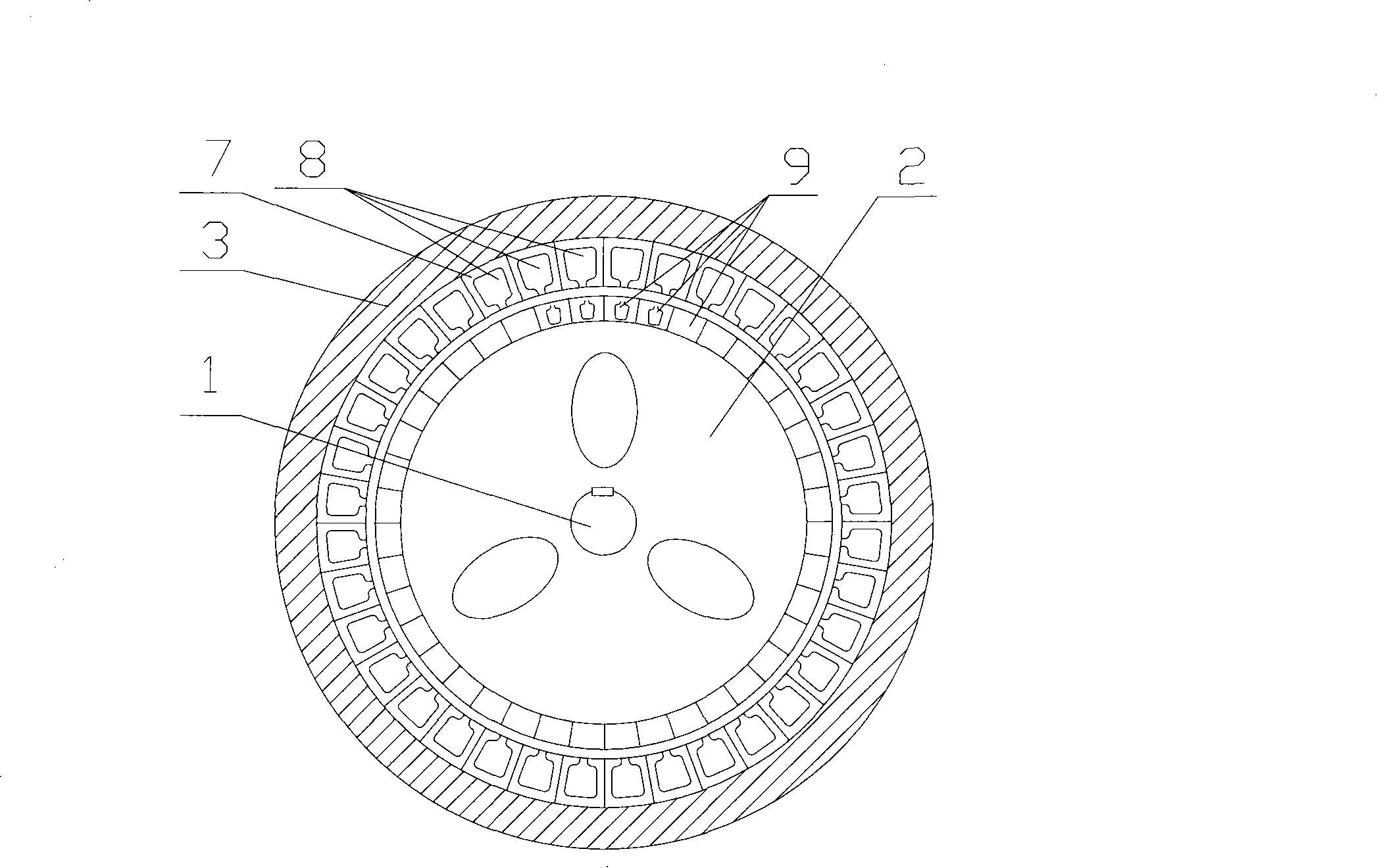

[0025] Each drawing of this embodiment adopts a form of expression similar to a sectional view, but in order to clearly show the structure and connection relationship of each part, no sectional line is drawn.

[0026] Such as Figure 1-Figure 3 As shown, the brushless AC excitation variable-speed co-frequency generator of the present invention includes a main shaft 1, a generator rotor 2 fixedly installed on the main shaft 1, and a generator stator 3 arranged around the generator rotor 2, and the generator The generator excitation coil 21 is installed on the turn 2, the generator armature coil 31 is installed on the generator stator 3, the generator stator 3 is installed on the main shaft 1 through the bearing, and the generator rotor 2 is fixedly installed on the main shaft 1.

[0027] The number of stator poles of this generator is not equal to the number of rotor poles. The specific method is: divide the circumference of the generator stator 3 into two or more stator secto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com