Novel edge-collapse proof unfilled corner proof gripper for silicon crystal-bar slicer

A slicing machine and silicon ingot technology, which is applied in manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems affecting the utilization rate of silicon ingot slicing materials, and achieve the effect of reducing edge chipping rate and preventing edge chipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

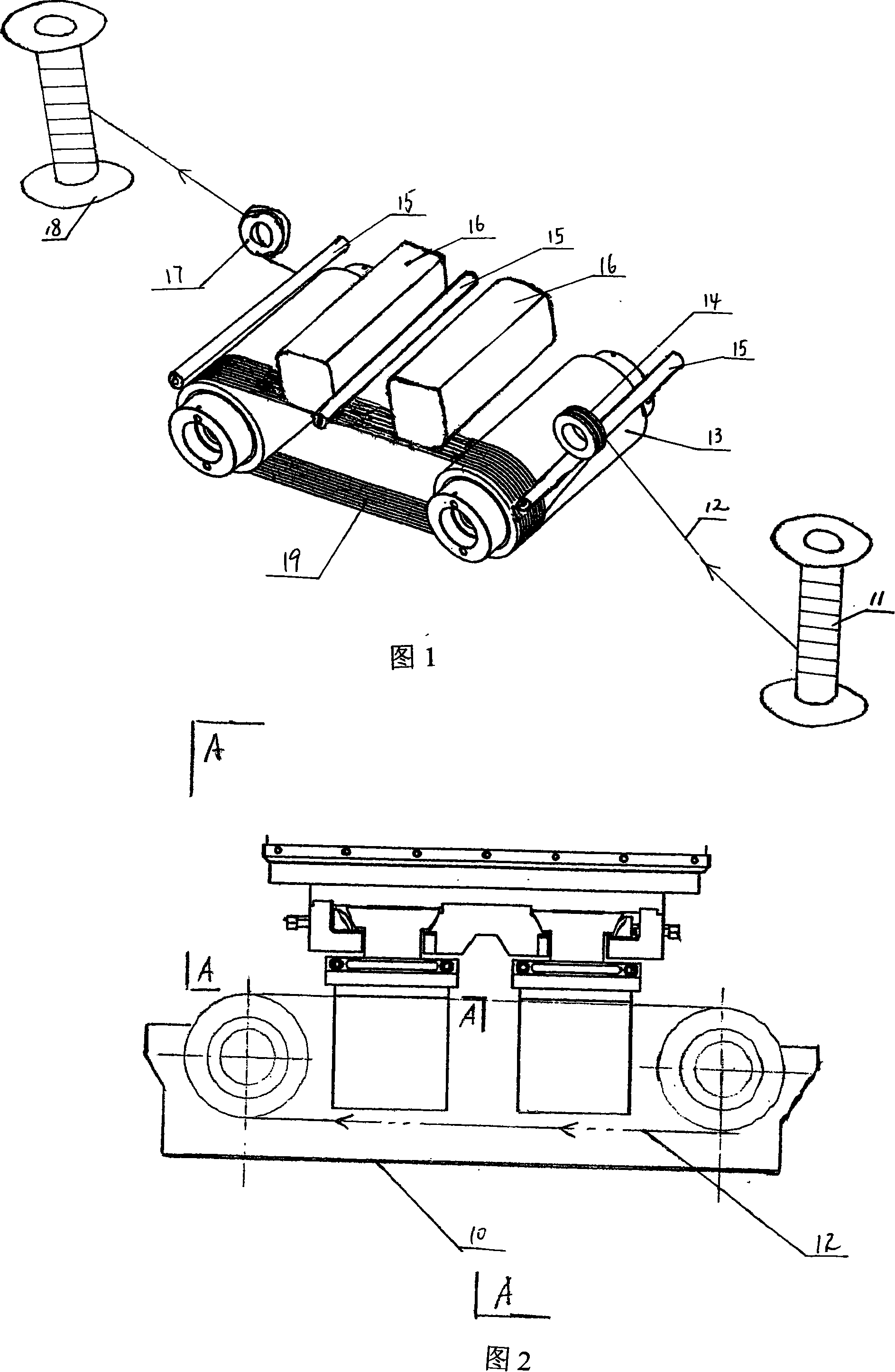

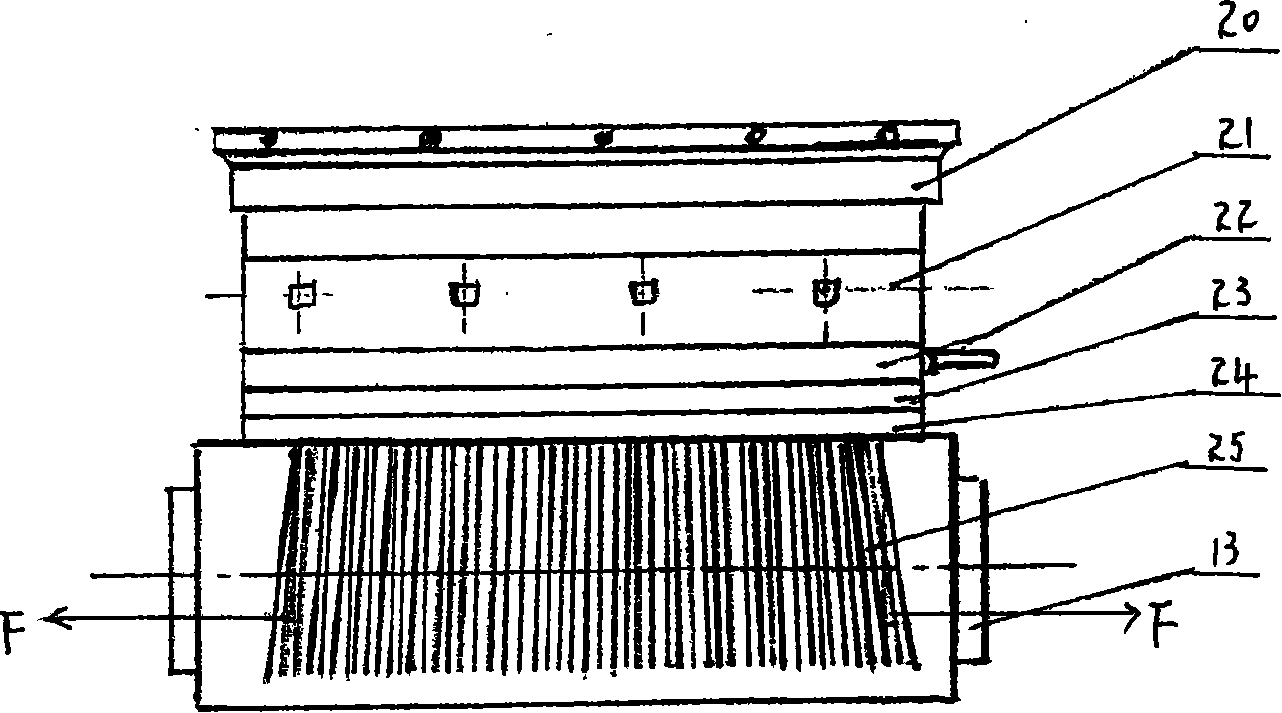

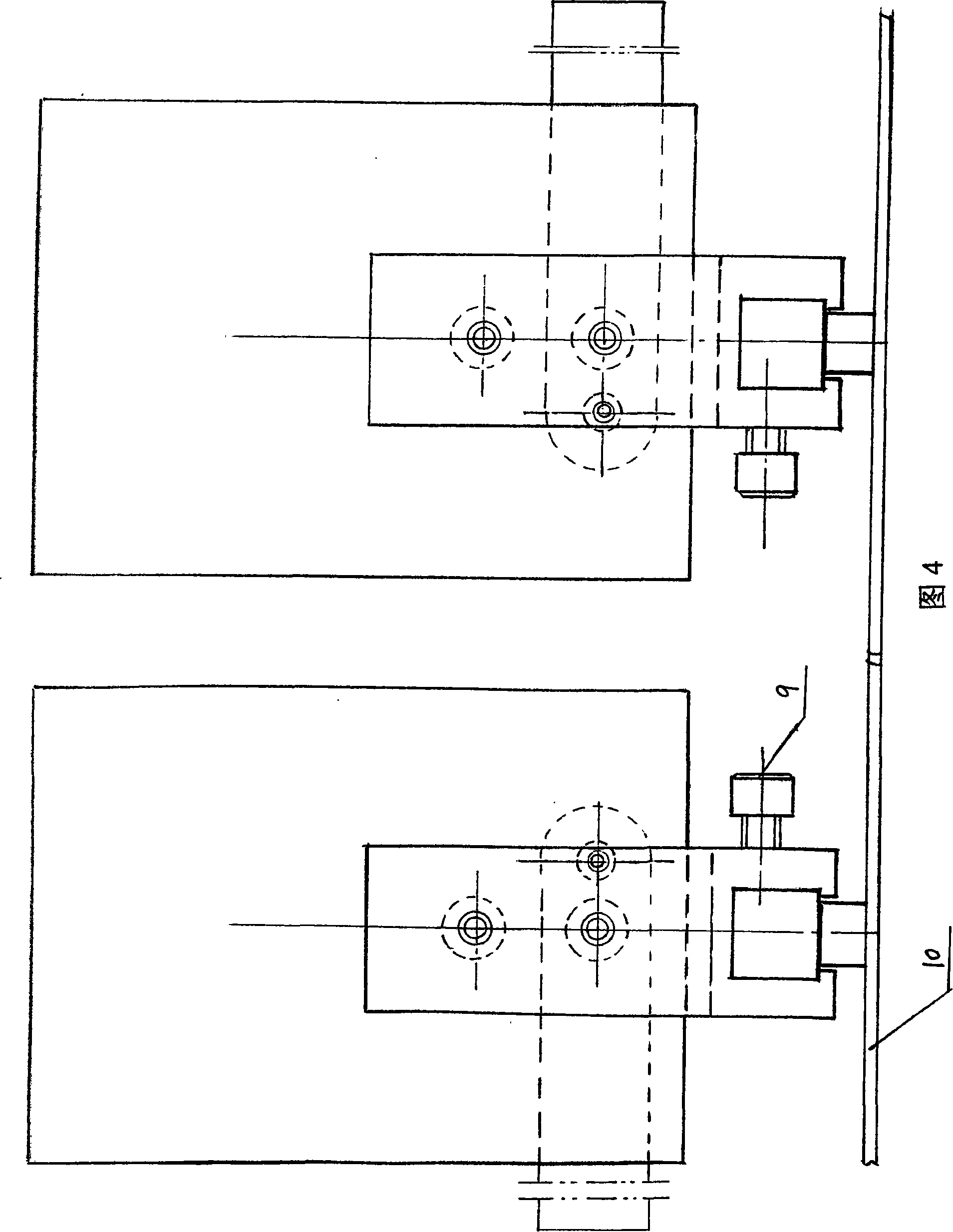

[0021] Referring to FIGS. 4 to 5 , the novel anti-collapsing and anti-corner silicon ingot slicer fixture of the present invention is mainly composed of a guide rail 6 , a sliding block 2 , a baffle plate 1 and a scale 4 . Described guide rail 6 has two, each one of left and right, and guide rail 6 two ends are fixed on the debris box 10 of slicer with bolt 8 and nut 7 parallel fixtures. The cooperation of bolt 8 and nut 7 can facilitate assembly and disassembly of the clamp.

[0022] There are four sliding blocks 2, and the four sliding blocks 2 are set on both sides of the two guide rails 6 in pairs. The block part is sleeved on the guide rail 6, and the horizontal block part of the sliding block 2 is fixedly connected with the guide rail 6 with screws III9. Loosen the screw III9 to adjust the front and rear positions of the slide block 2,

[0023] Described baffle plate 1 also has four, and four baffle plates 1 are fixedly connected in the vertical block inboard of corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com