Machine for seaming socks head

A sewing machine and sock toe technology, applied to sewing machines, sewing machine components, program-controlled sewing machines, etc., can solve problems such as uneven trimming, uneven sock toe, and missing seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

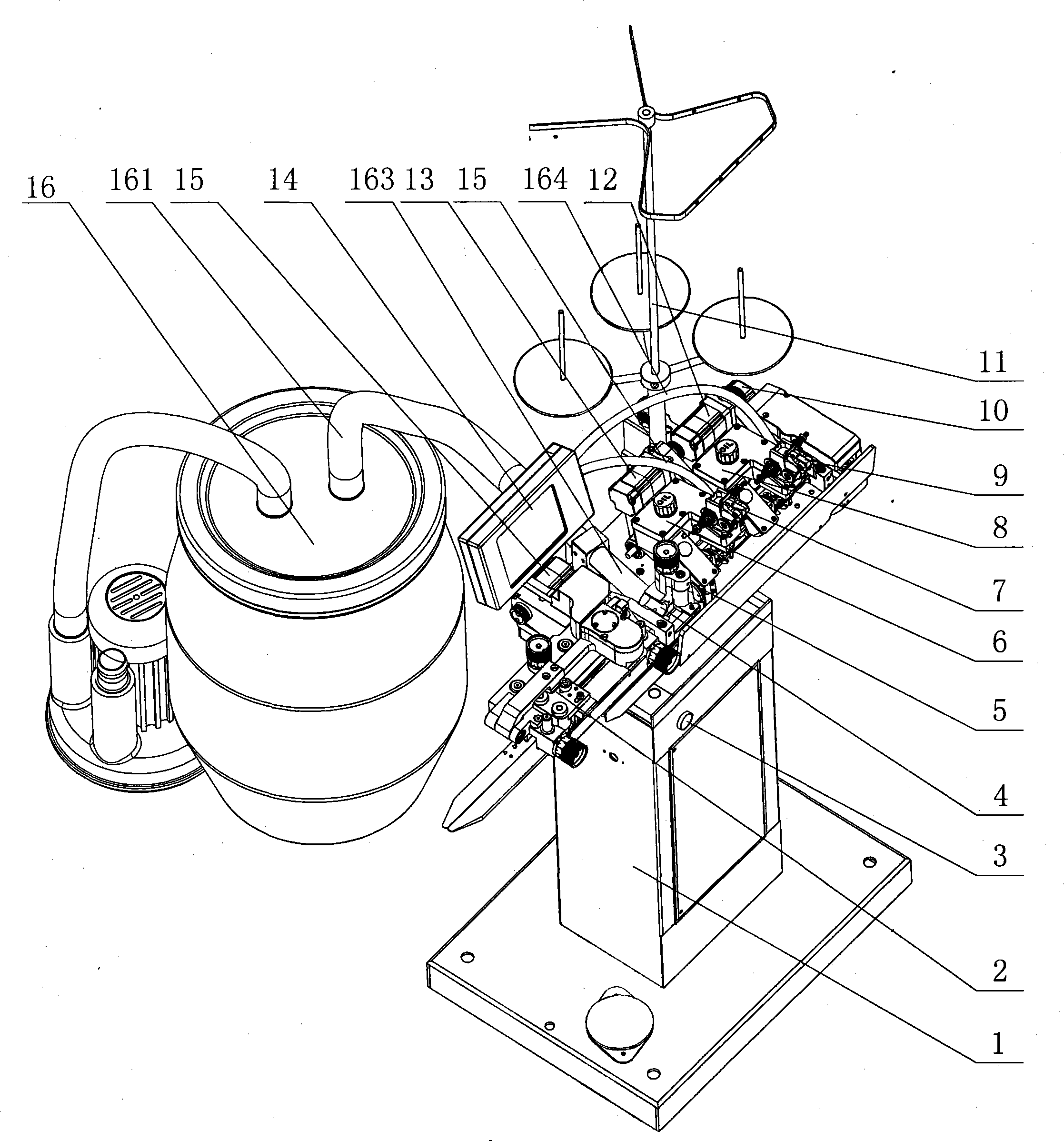

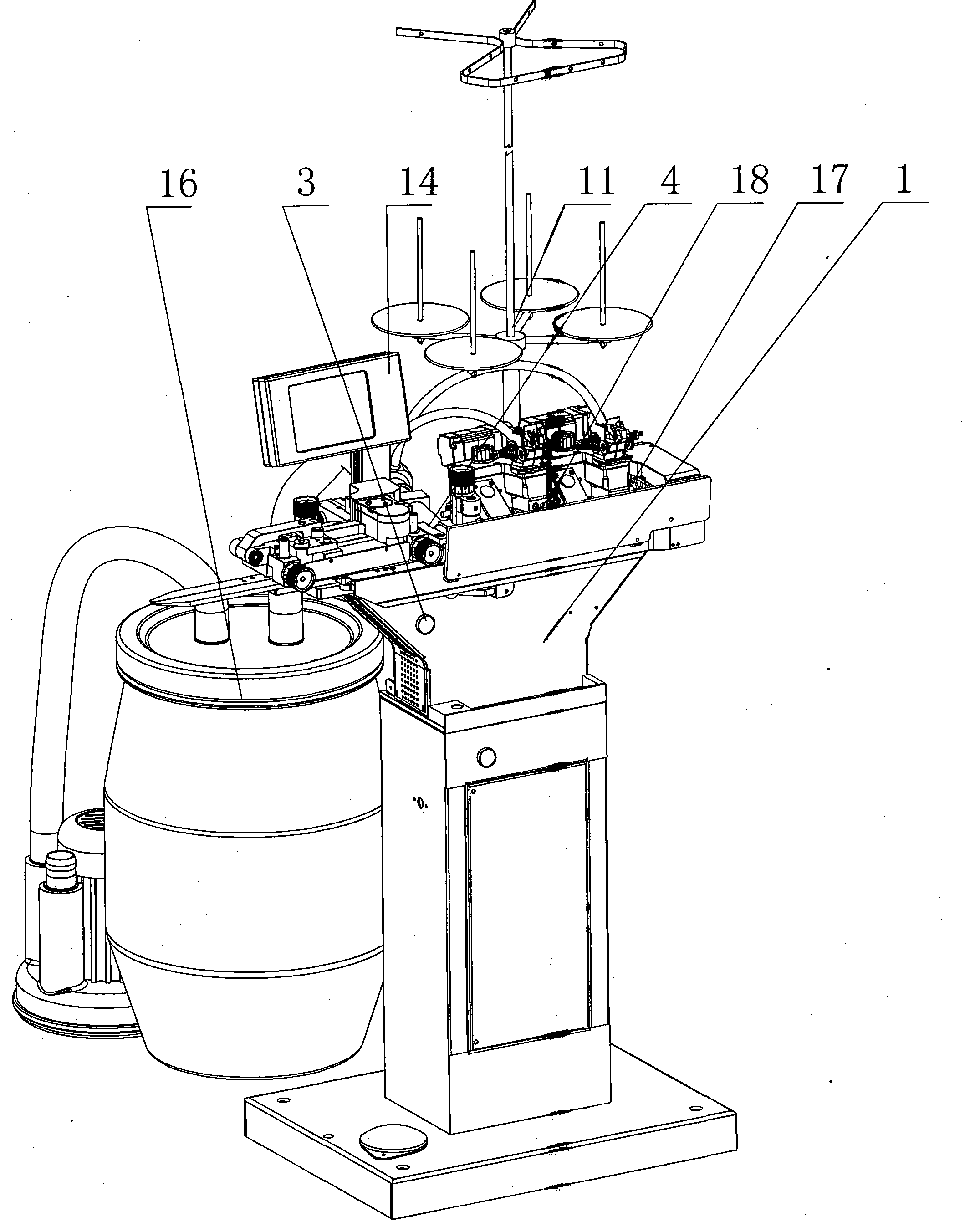

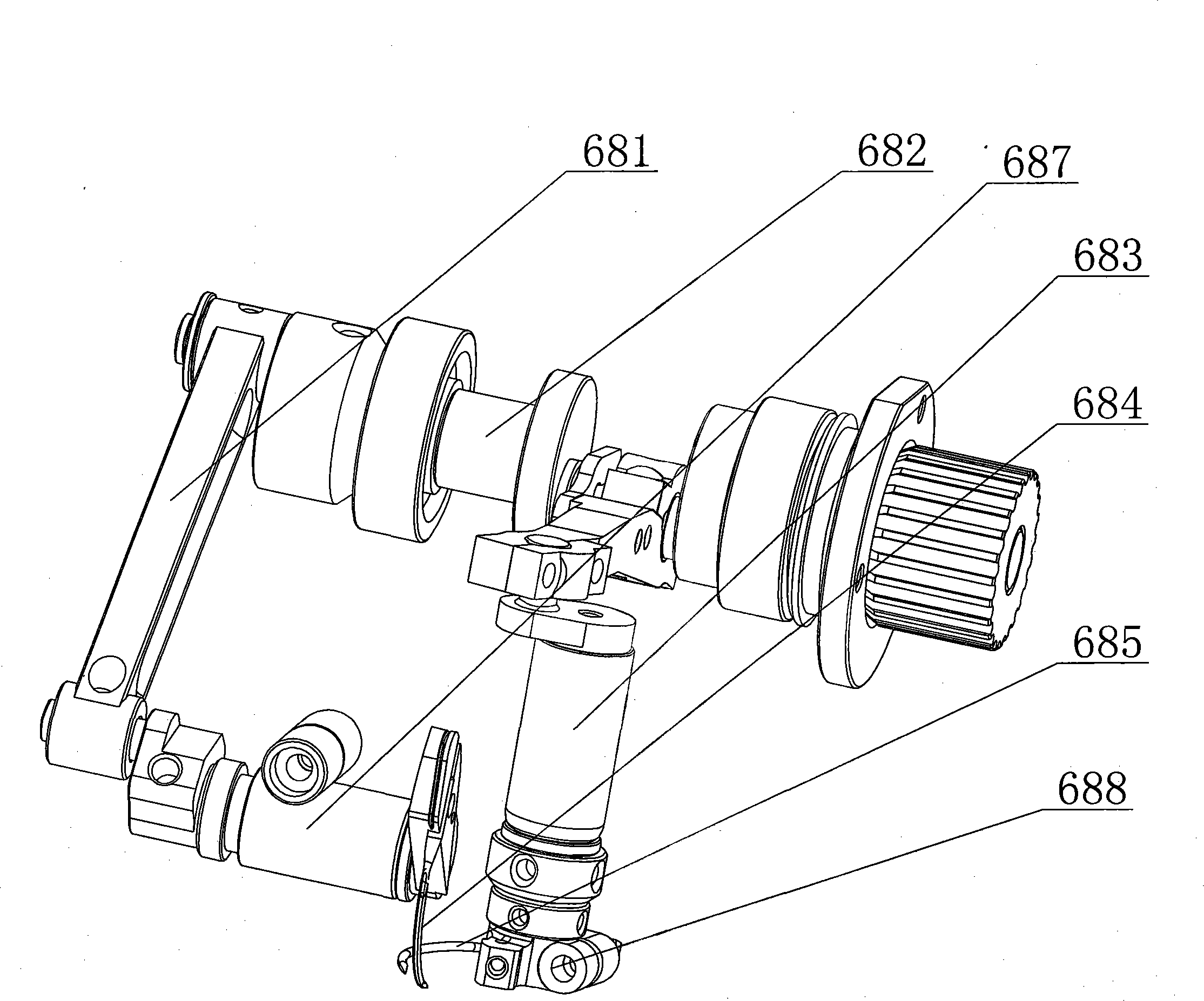

[0023] With reference to accompanying drawing, this sock toe sewing machine comprises feeding device 2, cutting device, sewing device, conveying device, waste material recycling device 16 and frame 1, and pay-off frame 11 is installed on frame 1, and conveying device is installed on Below the sewing device, the feeding device 2 is driven by the feeding motor 15, the cutting device and the conveying device are driven by the conveying motor 10, the sewing device is driven by the sewing motor, the feeding motor 15, the conveying motor 10 And sewing motor is controlled by microcomputer, and the parameter of its microcomputer control all can be set up and control from display screen 14, and this display screen 14 is a touch screen; Connect; the sewing device has a first sewing device 6 and a second sewing device 8, and the sewing motor has a first sewing motor 13 and a second sewing motor 12, and the first sewing device 6 is driven by the first sewing motor 13 , the second seaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com