Method for denoising bump-scrape acoustic emission signal based on discrete fraction cosine transform

A technology of acoustic emission signal and cosine transform, which is applied in the field of noise reduction of rubbing acoustic emission signal. The effect of acoustic emission signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

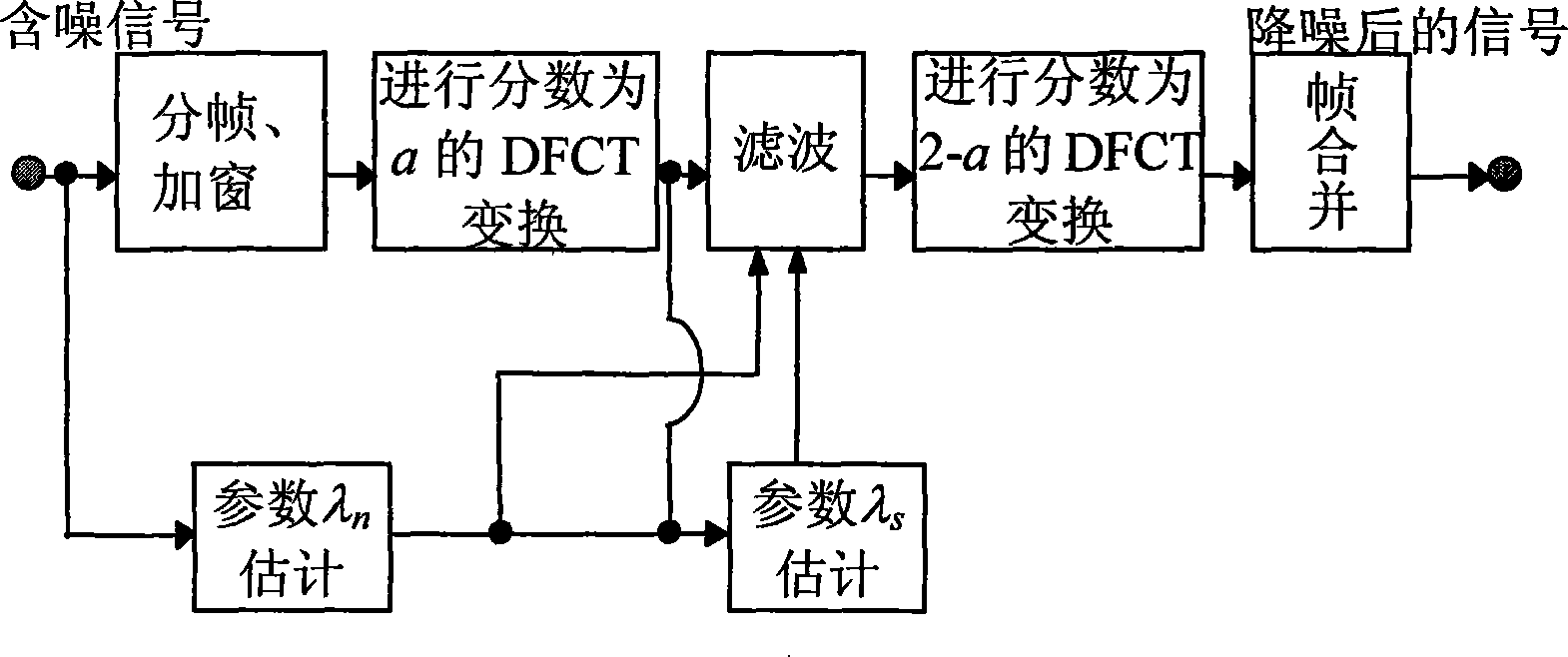

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

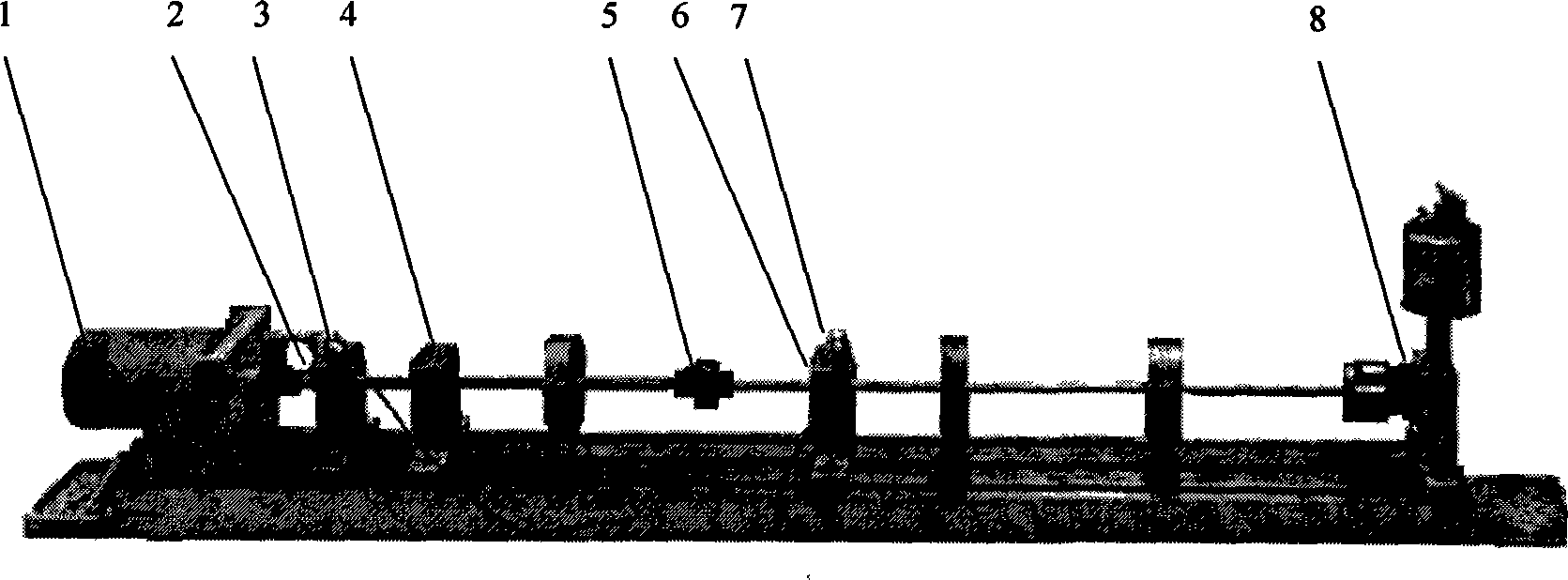

[0032] 1. Acoustic emission signal extraction and preprocessing

[0033] 1. Acoustic emission signal extraction

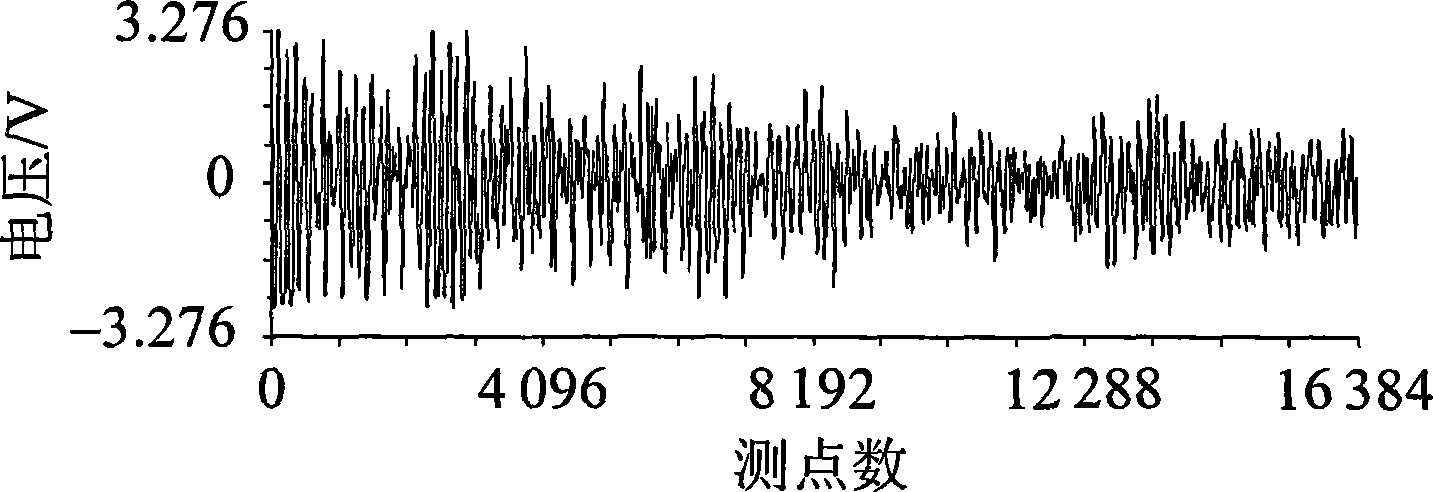

[0034] This test uses a 3-support 2-span rotor system, such as figure 1 shown. The three bearings, that is, the first bearing 2 , the second bearing 6 and the third bearing 8 are all hydrodynamic lubricated sliding bearings, the friction point 4 is close to the motor 1 , and the first acoustic emission sensor 3 is close to the friction point 4 . The second acoustic emission sensor 7 is located at the other end of the coupling 5 . The acoustic emission signal waveforms extracted by the first acoustic emission sensor 3 and the second acoustic emission sensor 7 can be used to analyze the attenuation of acoustic signal propagation and the signal distortion after coupling through a discontinuous medium. In the experiment, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com