Composite fire detector special for field

A fire detector and field technology, which is applied in the field of field-specific composite fire detectors, can solve the problems of high false alarm rate of detectors, affecting fire extinguishing time, and detector interference, etc., achieves fast temperature change and flame response time, and saves fire extinguishing The effect of time and large area of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

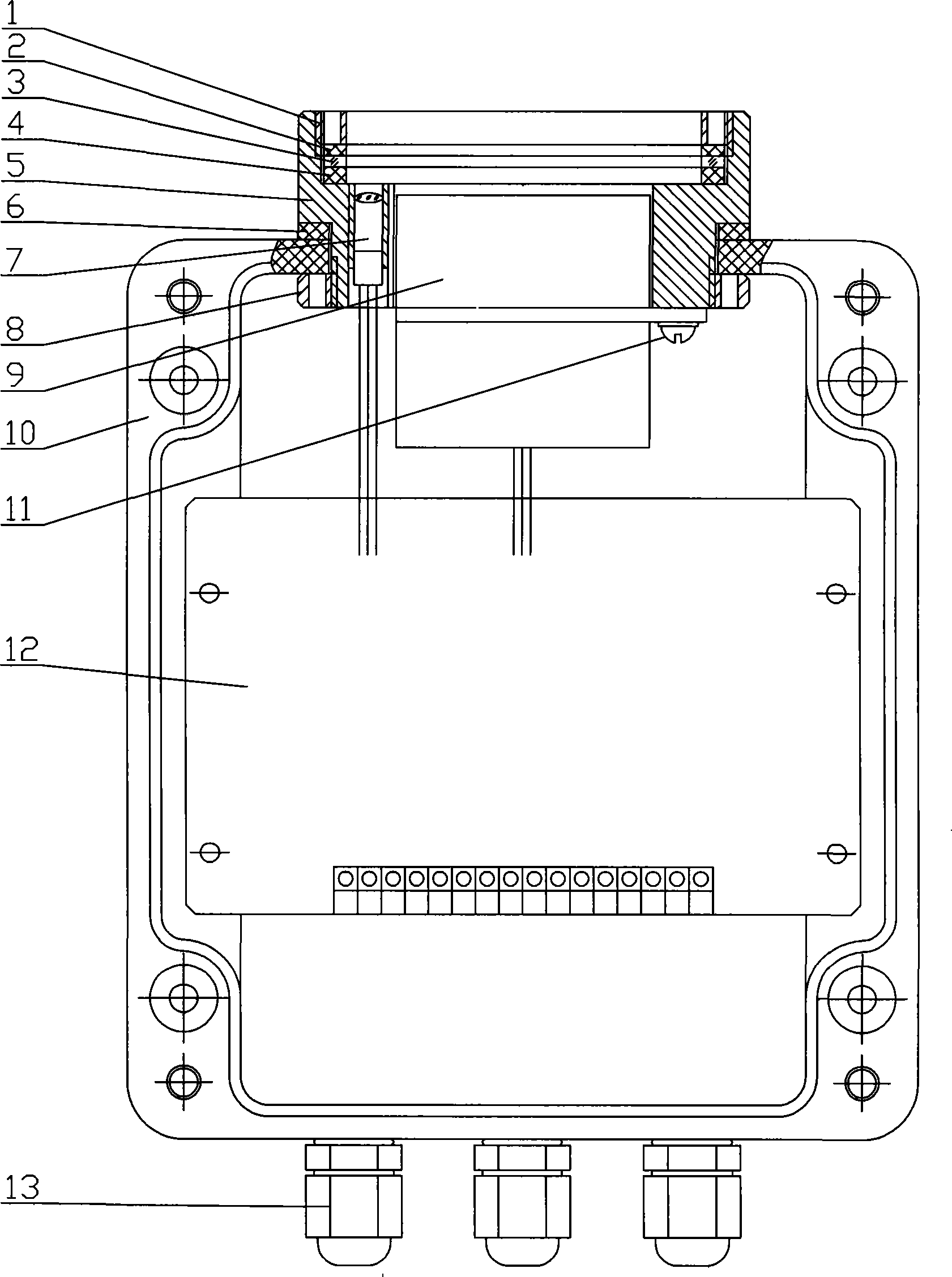

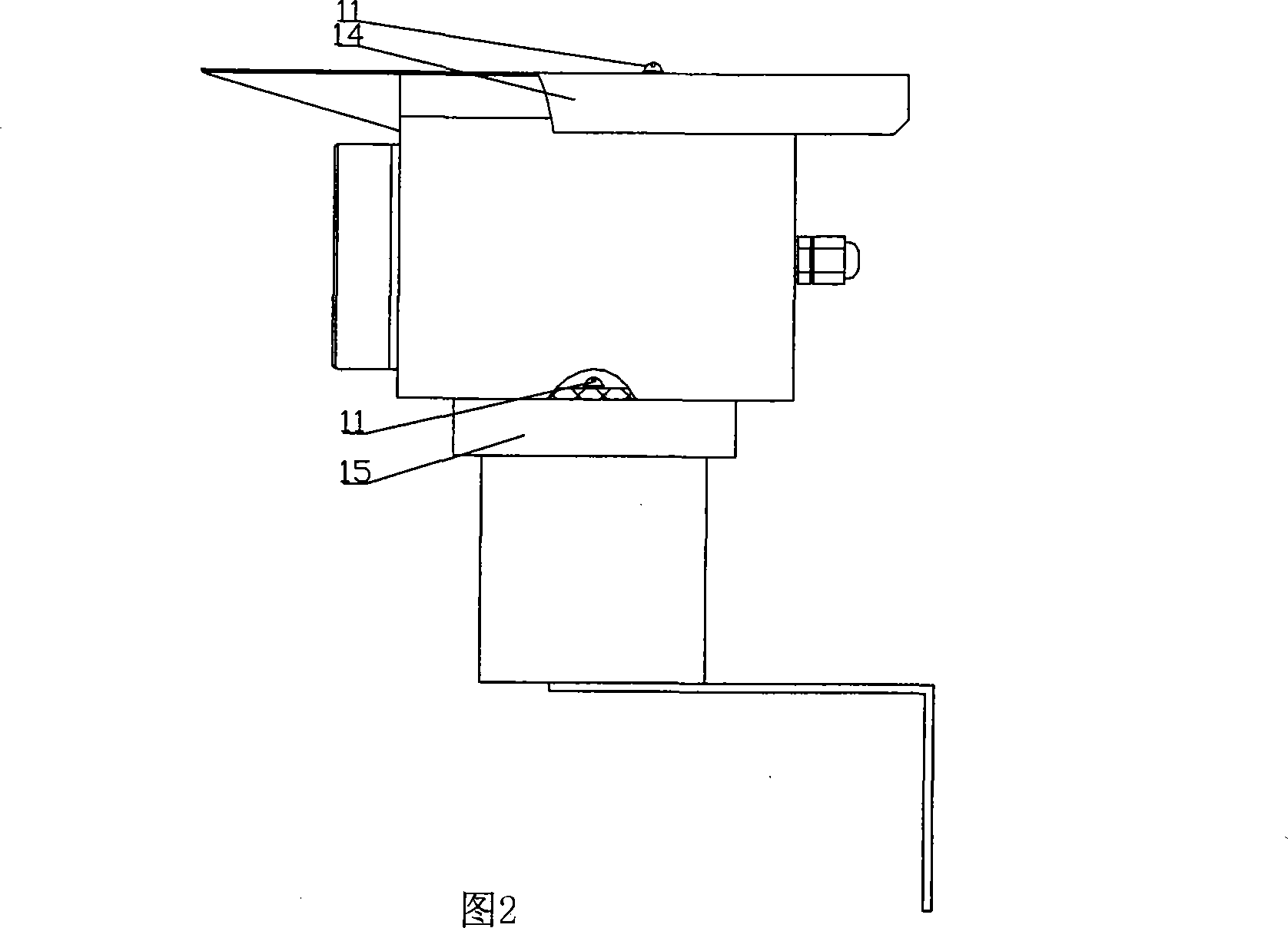

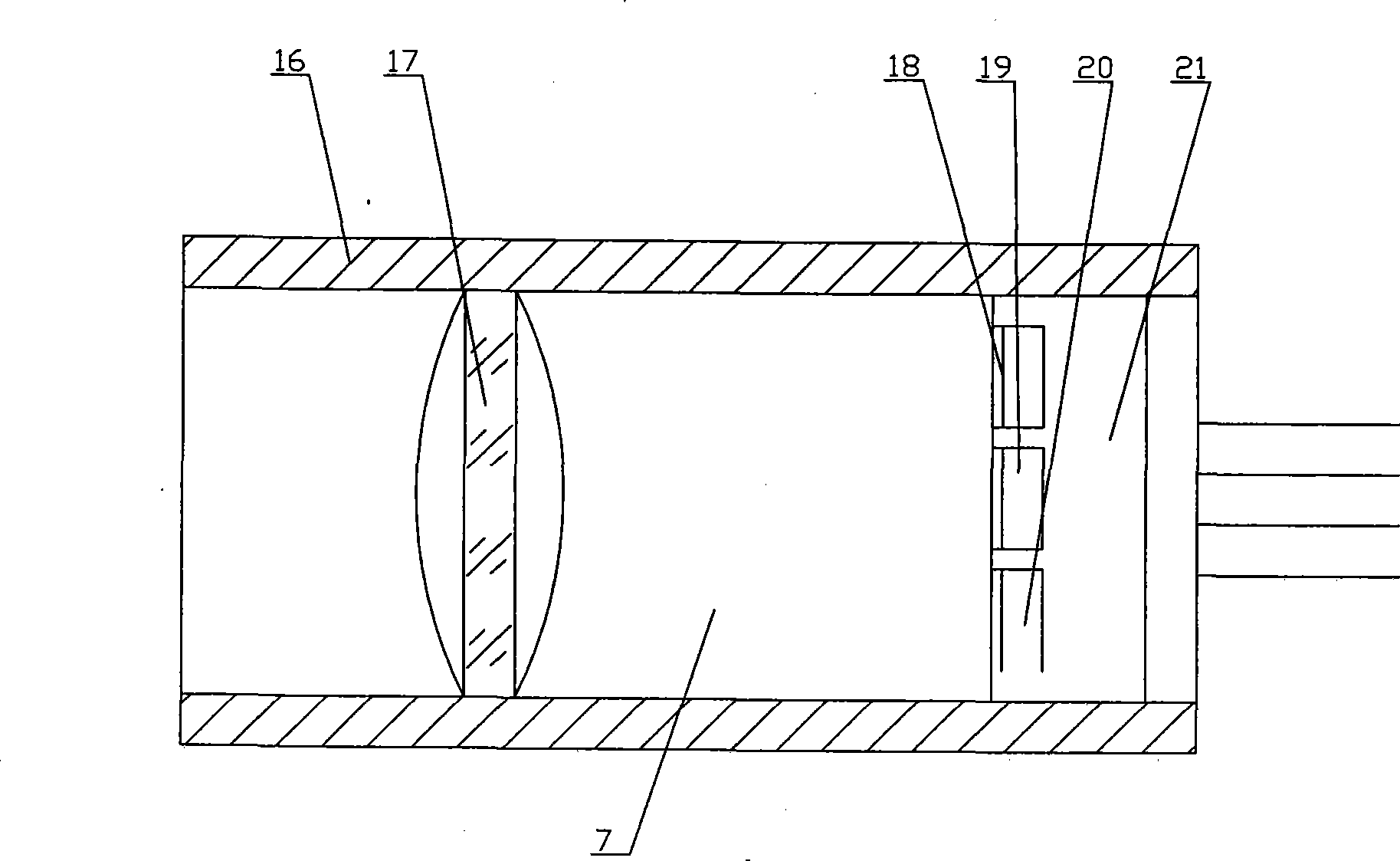

[0021] The present invention mainly consists of a pressing block 1, a gasket 2, an infrared-transmitting quartz glass 3, an upper sealing ring 4, a mounting block 5, a lower sealing ring 6, an infrared sensor assembly 7, a fixing nut 8, a CCD part 9, a box body 10, Screw 11, electronic circuit board 12, inlet and outlet connectors 13, rain cover 14, pan / tilt 15, condenser lens jacket 16, condenser lens 17, infrared temperature sensor 18, infrared flame sensor 19, reference sensor 20 and composite infrared sensor 21, etc. .

[0022] Such as figure 1 , shown in Fig. 2: the present invention adopts infrared sensor assembly 7 and CCD part 9 to form composite detector. The infrared sensor assembly 7 is composed of a condenser lens housing 16 , a condenser lens 17 and a composite infrared sensor 21 ; the composite infrared sensor 21 is composed of an infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com