Left, right, right three-section type spiral winding method and structure of energy-saving filament

A winding method, a three-stage technology, applied to the right, the winding structure of the filament, the right three-stage spiral winding method and structure, and the left field of the energy-saving filament. Problems such as twisted rings and electronic powder falling off when touched, achieve the effect of low production cost, high pass rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

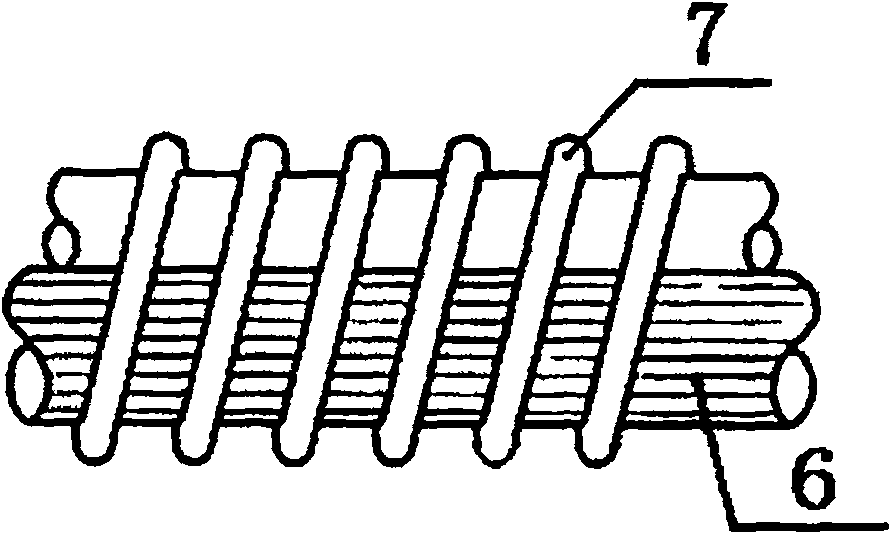

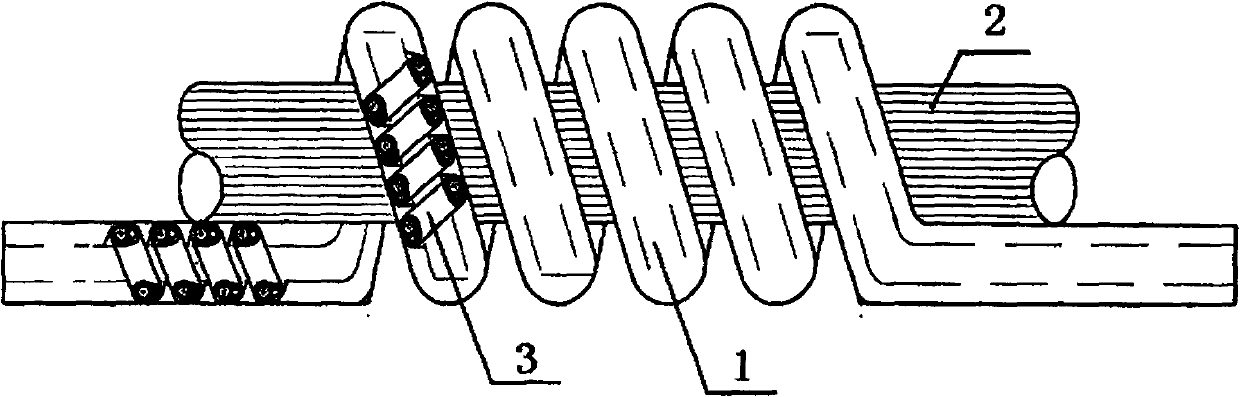

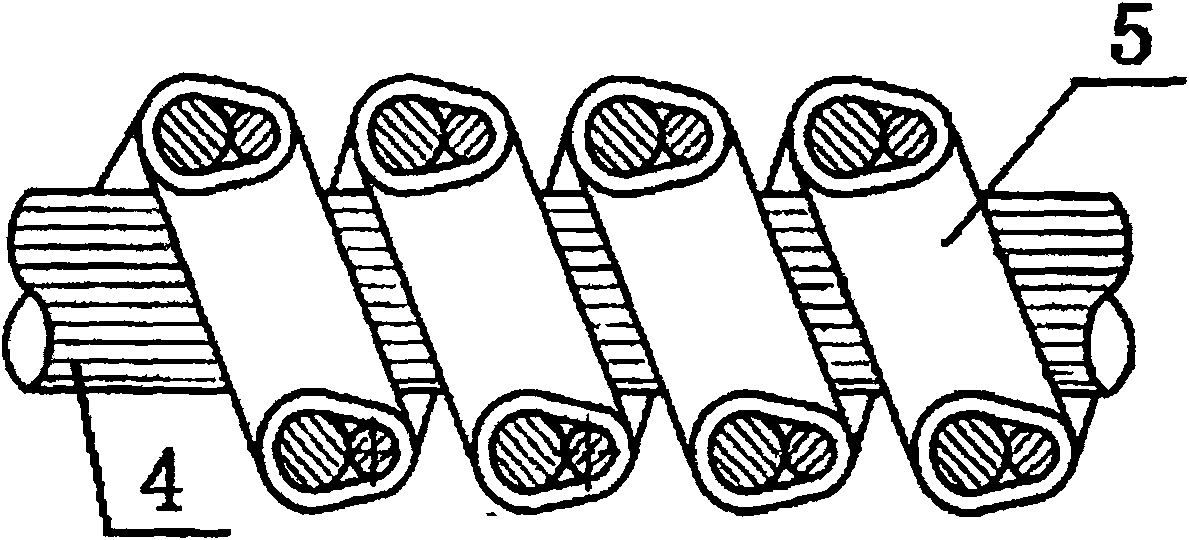

[0014] The embodiment of the present invention: it comprises a helical filament body 1, and the filament body 1 is composed of a mandrel 2 and a filament secondary winding body 3 wound around the periphery of the mandrel 2, as shown in the attached figure 1 The filament secondary winding body 3 is composed of a molybdenum core wire 4 and a filament primary winding body 5 wound around the periphery of the molybdenum core wire 4, as shown in the attached figure 2 As shown; the primary winding body 5 of the filament is composed of a molybdenum core wire 6 and a tungsten wire 7 wound around the periphery of the molybdenum core wire 6, as shown in the attached image 3 shown. The primary winding body 5 of the filament is wound on the molybdenum core wire 4 in a right helical manner, the secondary winding body 3 of the filament is wound on the mandrel 2 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com