Method and device for refining or descaling thin slabs and strips in hot strip mills, strip treatment installations or the like

A technology for descaling and stripping, applied in cleaning methods and appliances, workpiece cleaning devices, workpiece surface treatment equipment, etc., can solve the problems of laborious, inability to switch to hot rolling and strip surface treatment, etc., and achieve less energy consumption , Inhibition of re-formation, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

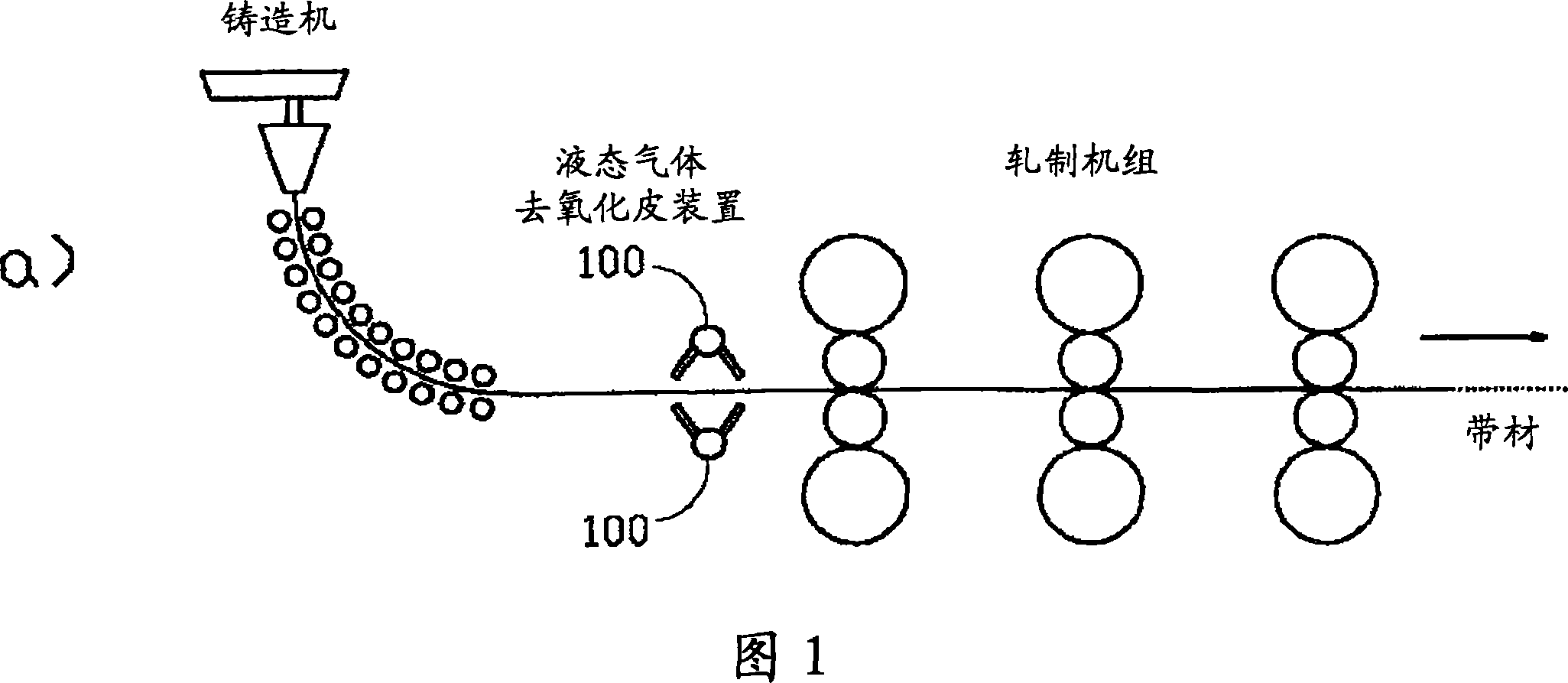

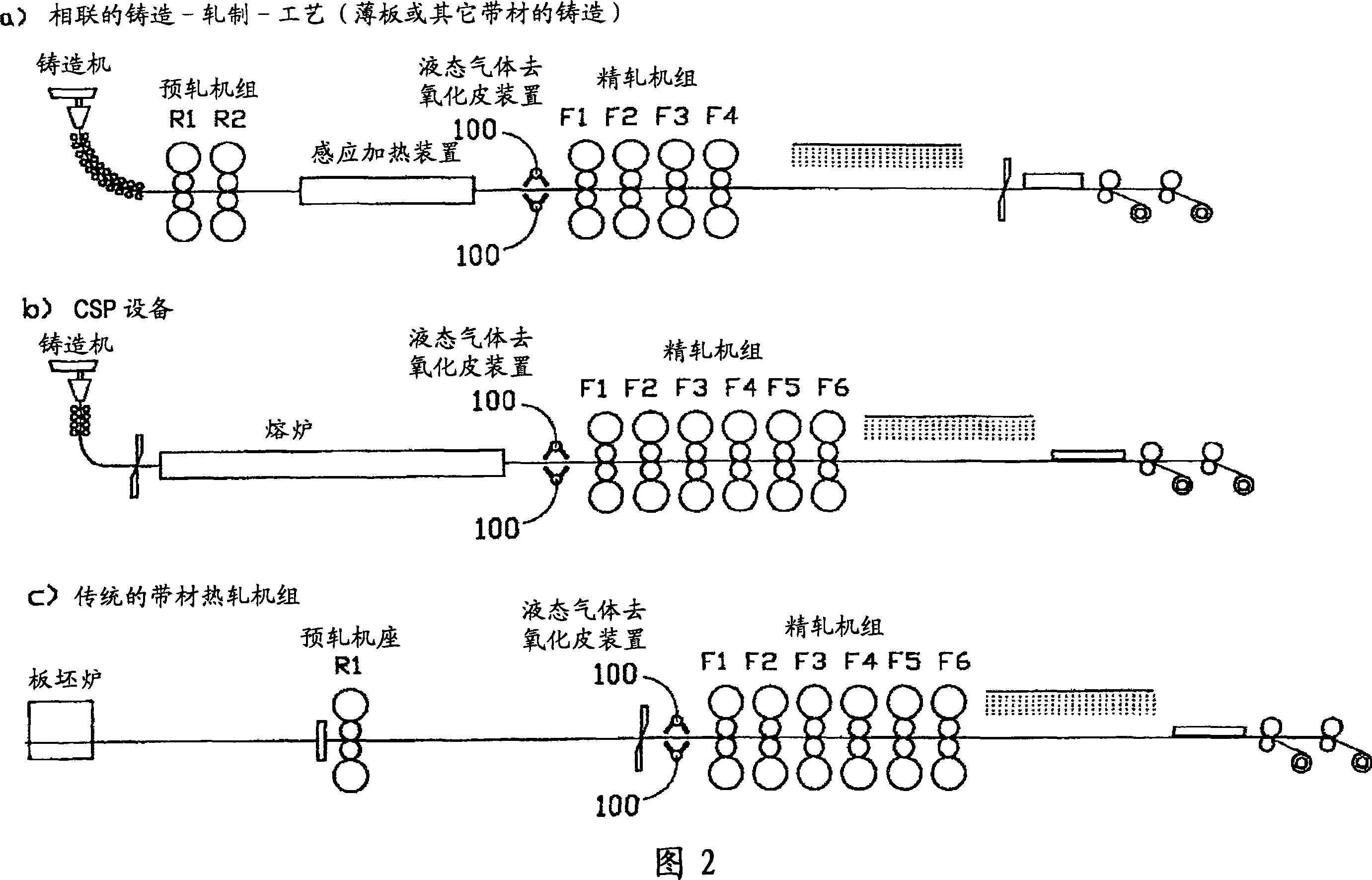

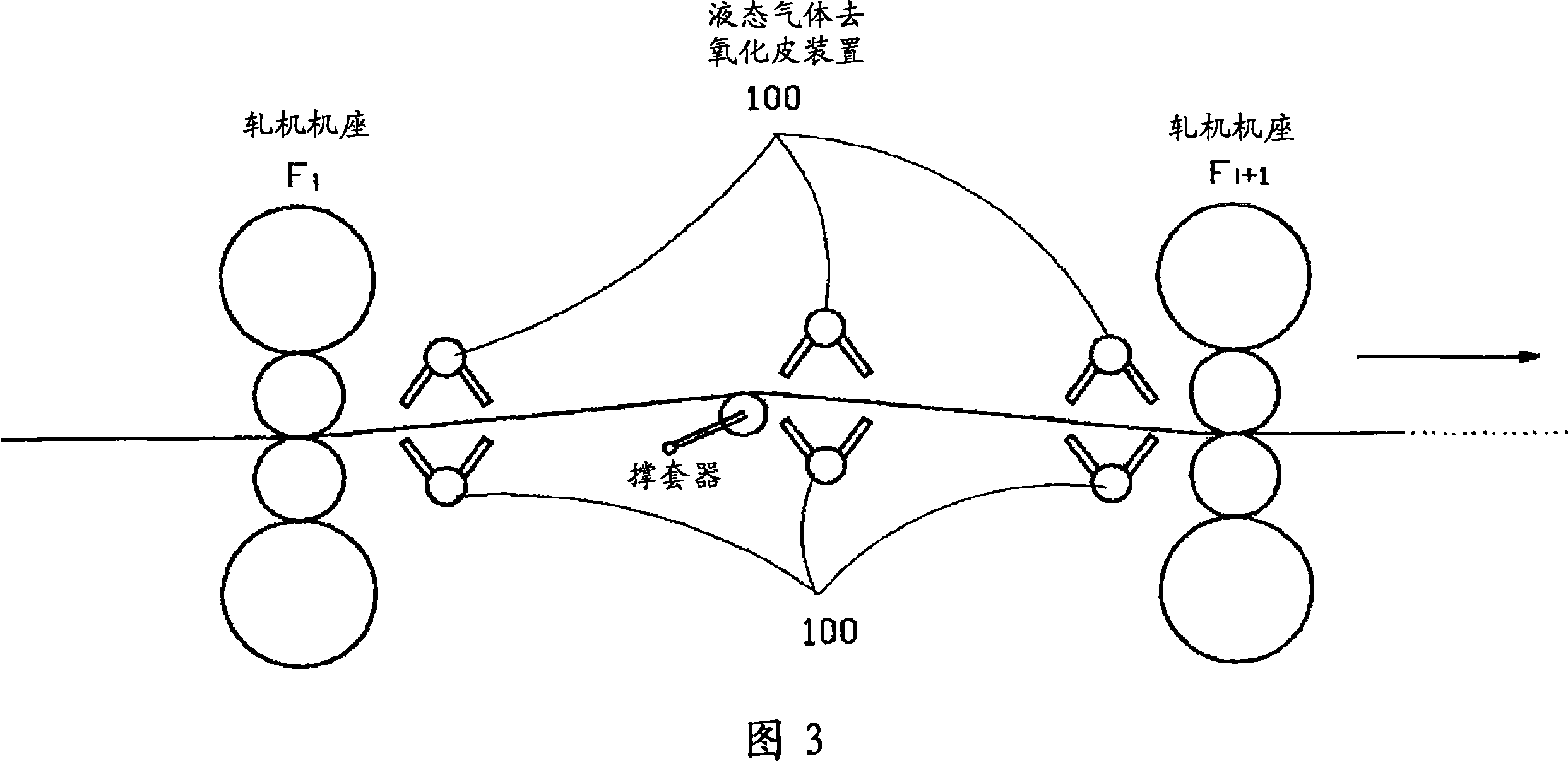

[0038] Possible installation positions of a descaling unit with liquid gas in a strip plant are as follows:

[0039] 1. As a supplementary device for the segment straightening machine. That is to install nozzles in the segment straightening machine or directly on the segment straightening machine. Since the extraction device is already installed here, the installation location described can also be used for retrofitting.

[0040] 2. The descaling unit with liquid gas can even replace the segment leveling machine as a "stand-alone" application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com