Method of pre-heating fuel and comburent for oxy-burners, using combustion air pre-heating installations

An oxygen-enriched oxidant and burner technology, which is used in combustion methods, combustion equipment, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

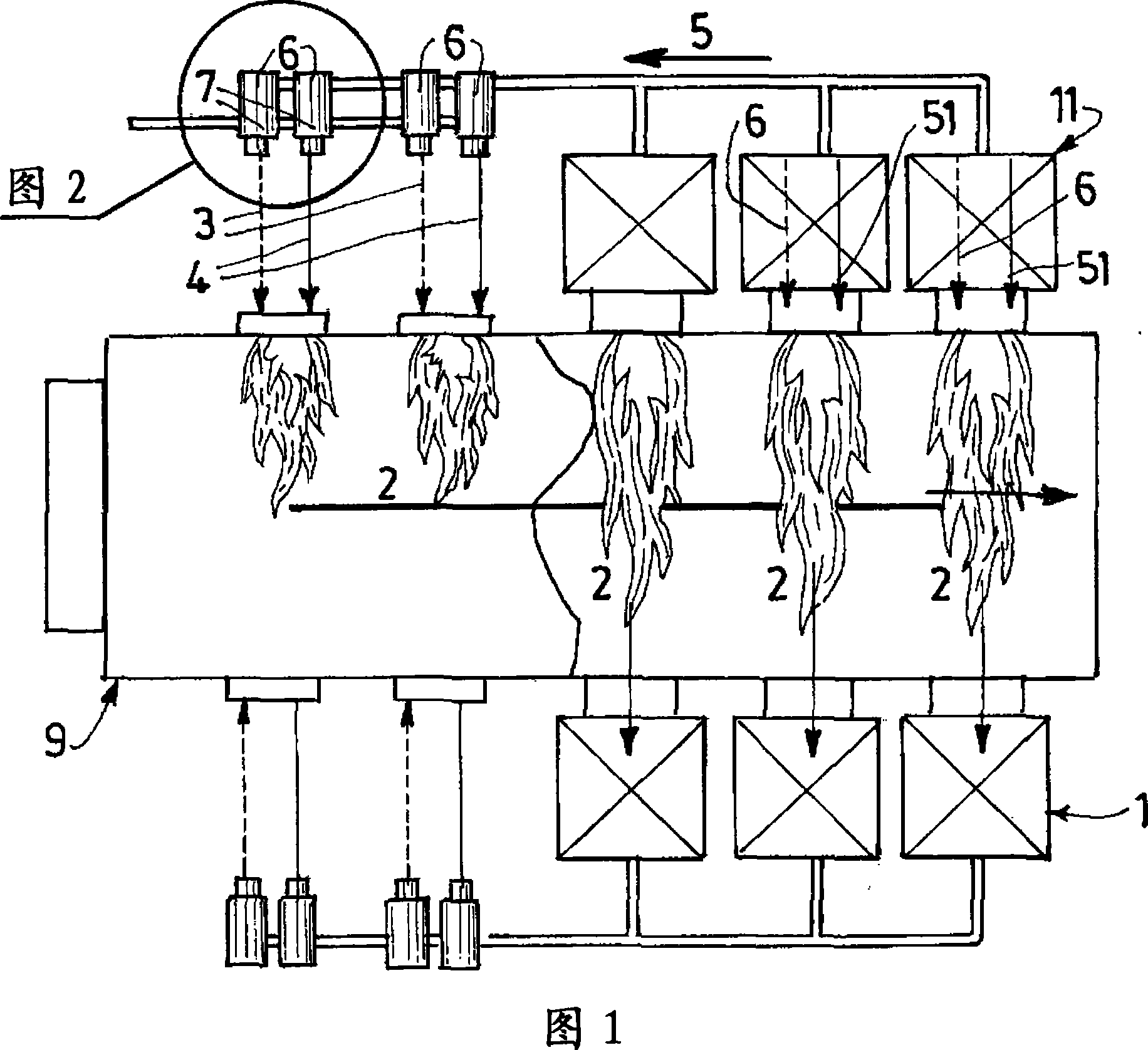

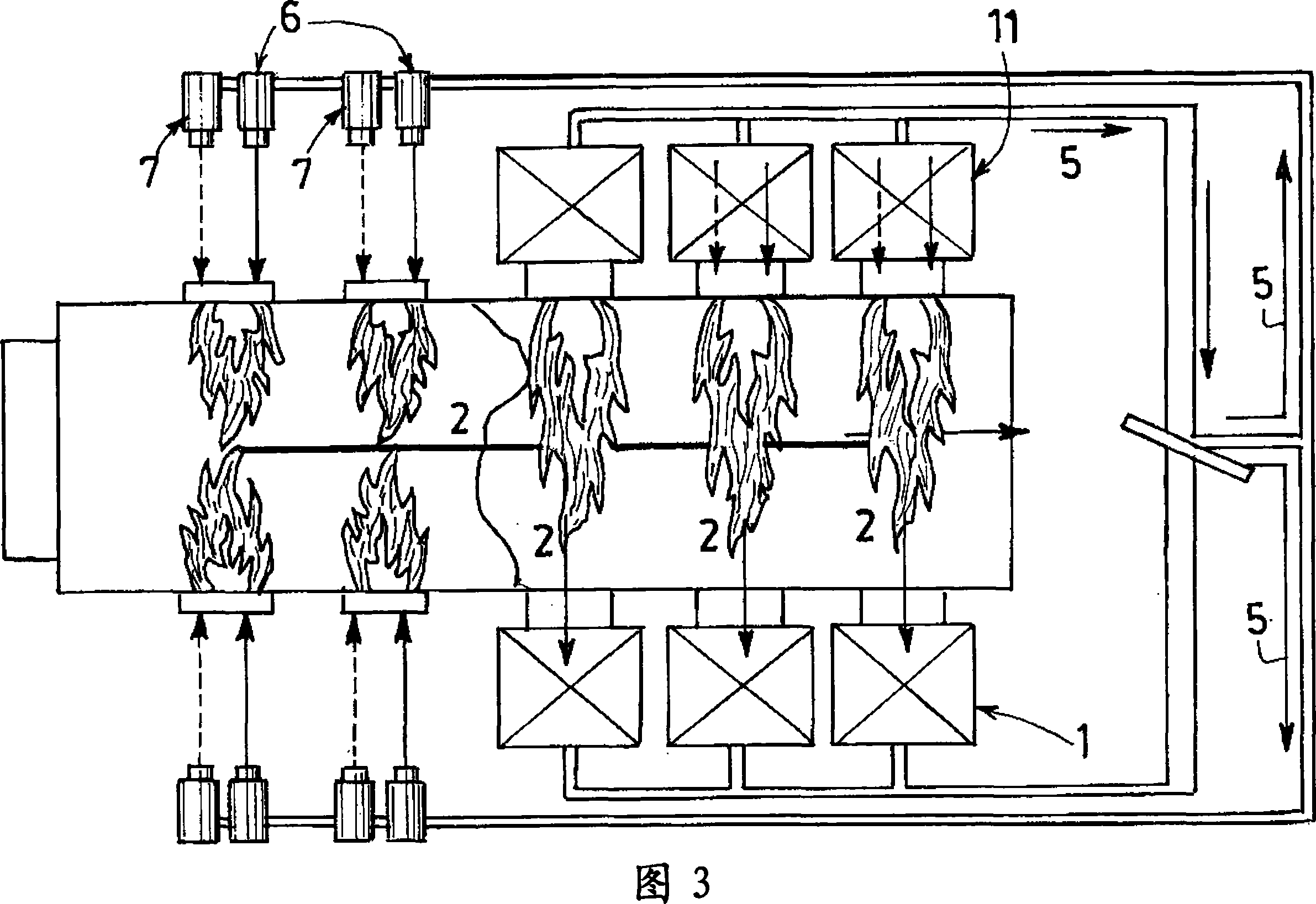

[0023] Figure 1 illustrates the method of the invention. Kiln 9 is installed with:

[0024] - upstream, with an oxy-fuel burner fed with fuel 4 and oxy-enriched oxidizer 3;

[0025] - Downstream, there is a burner fed with fuel 6 and heated air 51;

[0026] - Regenerator 1 , which is fed with hot exhaust gas 2 from the kiln (regenerator 1 ) or returns hot air 5 , 51 (regenerator 11 ). The hot air 5 conveyed by the heat accumulator 11 is either used as combustion air 51 in the air burner or for preheating the fuel 4 and the oxygen-enriched oxidizer 3 of the oxy-fuel burner via the heat exchangers 6 , 7 . In this configuration, the hot air 5 from the regenerator 11 arranged on the same side as the kiln 9 only enables the air-fuel burner and the oxy-fuel burner located on the same side of the kiln to be fed and preheated respectively, The burners located on the other side of the kiln are not operating.

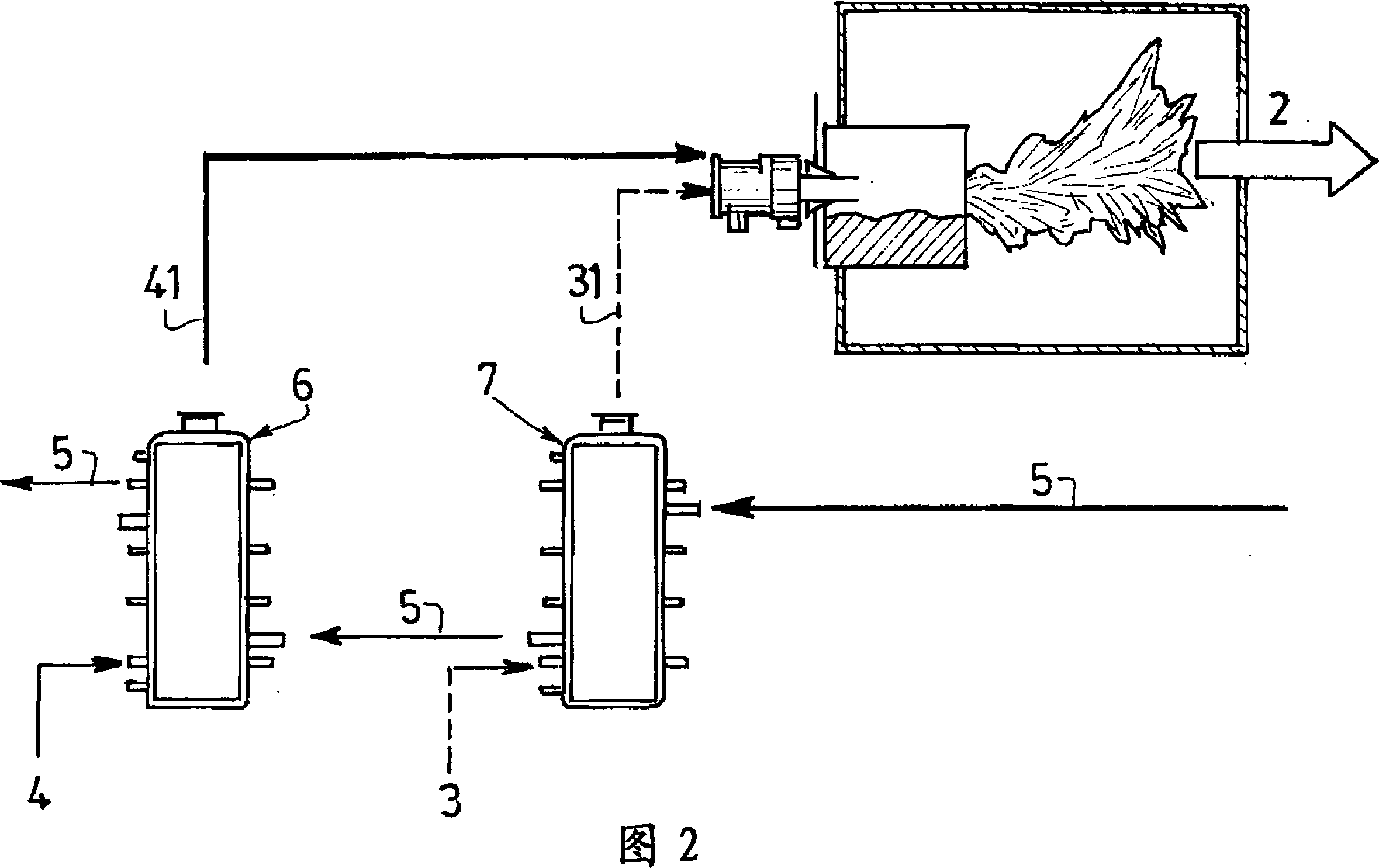

[0027] Figure 2 shows the preheating of the reactants: hot air 5 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com