Water sealing type ozone continuous sterilization device

A technology of a sterilization device and a water mixing device, which is applied to the preservation of fruits and vegetables, preservation of fruits/vegetables by freezing/refrigeration, and food preservation, etc., can solve the problems of human injury, restriction, and low efficiency, so as to prevent damage and reduce sterilization. Stress, prolonged retention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

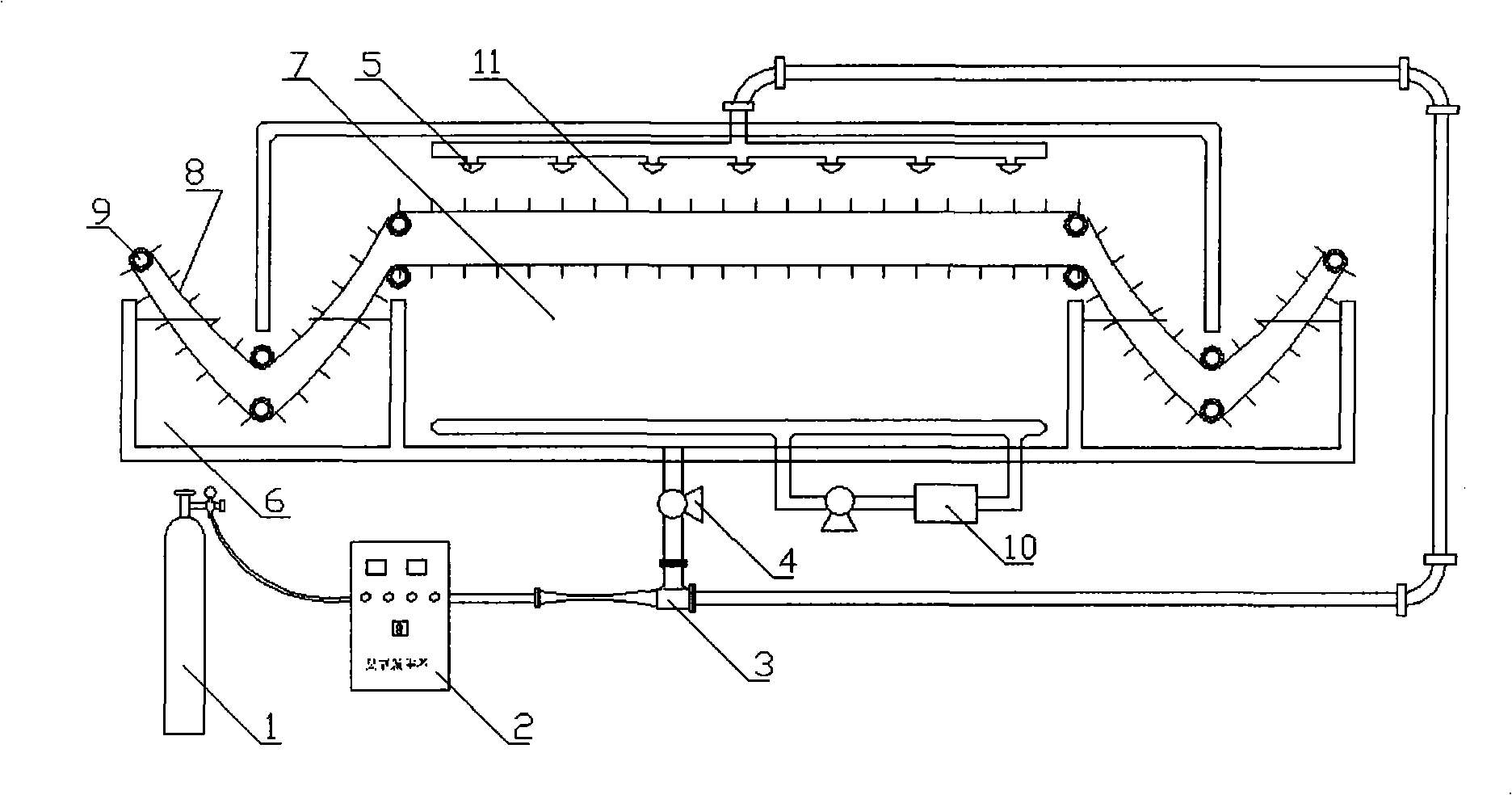

[0011] A best embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a water-sealed ozone continuous sterilization device includes: an oxygen bottle 1, an ozone generator 2, an air-water mixing device 3, the air-water mixing device 3 adopts a Venturi tube, and one end of the ozone generator 2 is connected to the oxygen bottle 1 The other end is connected with the gas-water mixing device 3; the two ends of the ozone water tank 7 are provided with an isolation tank 6 outside the tank wall; baffles are installed at regular intervals on the conveyor belt 8, and the chain and the gear 9 drive system are driven to run. The guide wheels at both ends of the mesh belt 8 are below the water surface of the isolation tank 6, and the guide wheels in the middle are set above the ozone tank 7, so that the conveying mesh belt 8 enters the device through the isolation tank 6, passes through the ozon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com