Bagging oral containing tobacco and manufacture method thereof

A technology of tobacco products and tobacco, which is applied in the field of tobacco, can solve problems such as residues, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

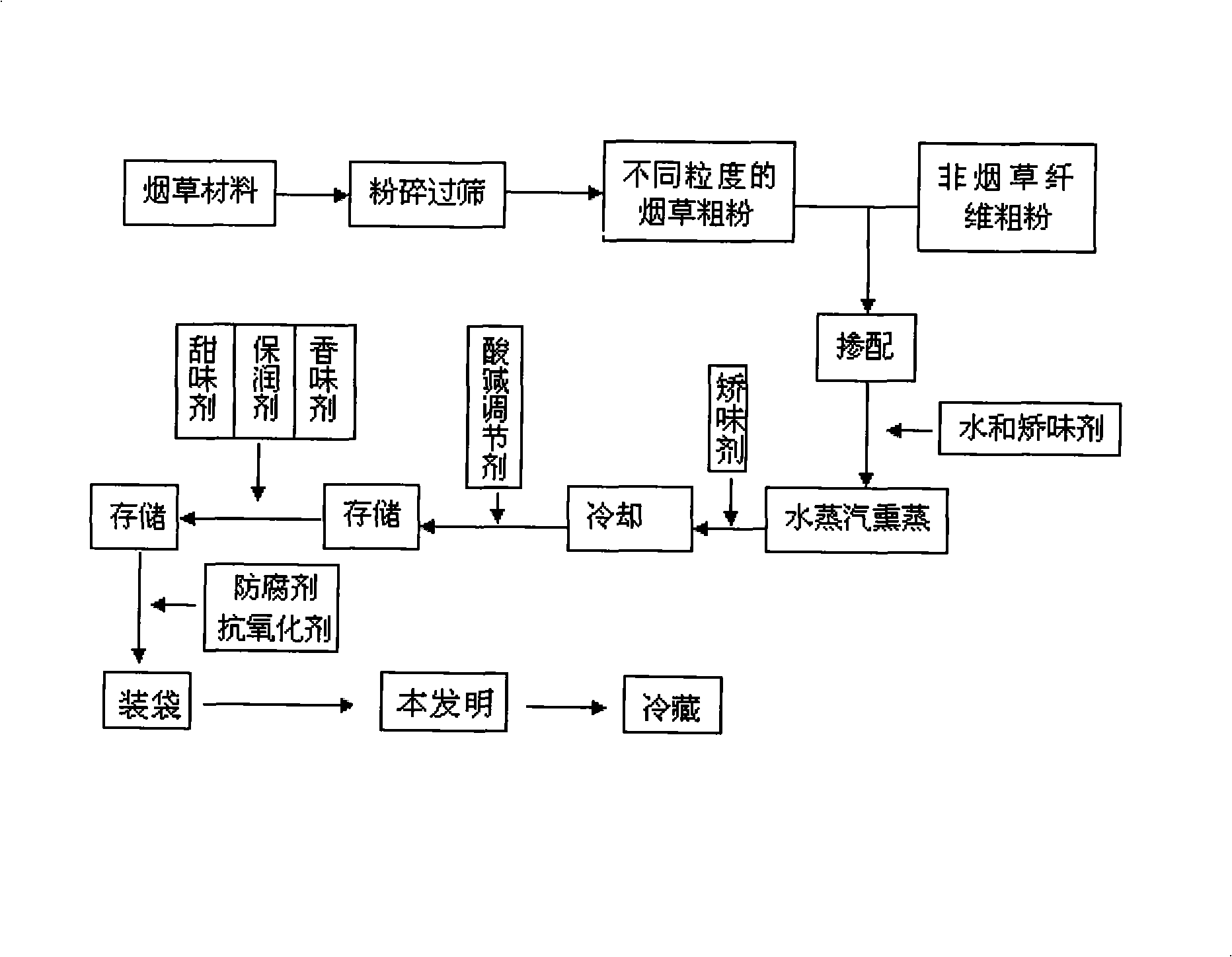

[0016] A formula consisting of 40 grams of water, 47 grams of burley tobacco, 1 gram of sodium bicarbonate, 10 grams of sodium chloride, 2 grams of propylene glycol, etc., according to the process shown in the attached figure: burley tobacco → crushing and sieving → different particle sizes Coarse tobacco powder→add water and sodium chloride→steam fumigation (temperature about 80℃, time 20 hours)→cool→sodium bicarbonate→storage→add propylene glycol→storage, then pack 0.5g per bag into 2cm *Keep refrigerated in a 1cm pouch.

Embodiment 2

[0018] A formula consisting of 41 grams of water, 42.5 grams of burley tobacco and oriental tobacco, 2 grams of sodium bicarbonate, 2 grams of sodium chloride, 8 grams of stevia, 4 grams of propylene glycol, and 0.5 grams of 2-butyrol, as shown in the attached drawing Process flow: Burley tobacco and oriental tobacco→crushing and sieving→coarse tobacco powder of different particle sizes→adding water, sodium chloride, blending→water vapor fumigation (temperature around 90°C, time 16 hours)→stevia→cooling→adding Sodium bicarbonate→storage→propylene glycol, 2-butynol→storage, processed into moist tobacco particles, and then packed into small bags of 2cm*1cm in size of 0.5g per bag, and stored in cold storage.

Embodiment 3

[0020] Composed of 30 grams of water, 32 grams of air-cured tobacco and burley tobacco, 1 gram of sodium carbonate, 10 grams of sodium chloride, 5 grams of mint, 4 grams of licorice, 15 grams of beet fiber, 2 grams of glycerol, and 1 gram of antioxidant According to the process flow shown in the attached drawing: air-dried tobacco and Burley tobacco→crushing and sieving→coarse tobacco powder of different particle sizes→adding beet fiber→adding water and sodium chloride blending→water vapor fumigation (at a temperature of about 70°C, Time 25 hours) → add mint, licorice blending → cooling → add sodium carbonate → store → add glycerin, antioxidant → store, process into moist tobacco particles, and then pack 0.5g in each bag into 2cm*1cm In a sachet, keep refrigerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com