Detachable can-type pallet case

A pallet box and tank-type technology, applied in the field of detachable tank-type pallet boxes, can solve the problems of inconvenient maintenance and cleaning, easily damaged pallet boxes, and inconvenient reuse, etc., and achieve good overall mechanical properties and impact resistance performance, reduced manufacturing costs, ease of maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to help illustrate the technical solution of the present invention, terms such as frame, cylinder, connecting plate, outrigger, etc. are used in the following description, and it should be understood that they should not be used as a limitation of the present invention.

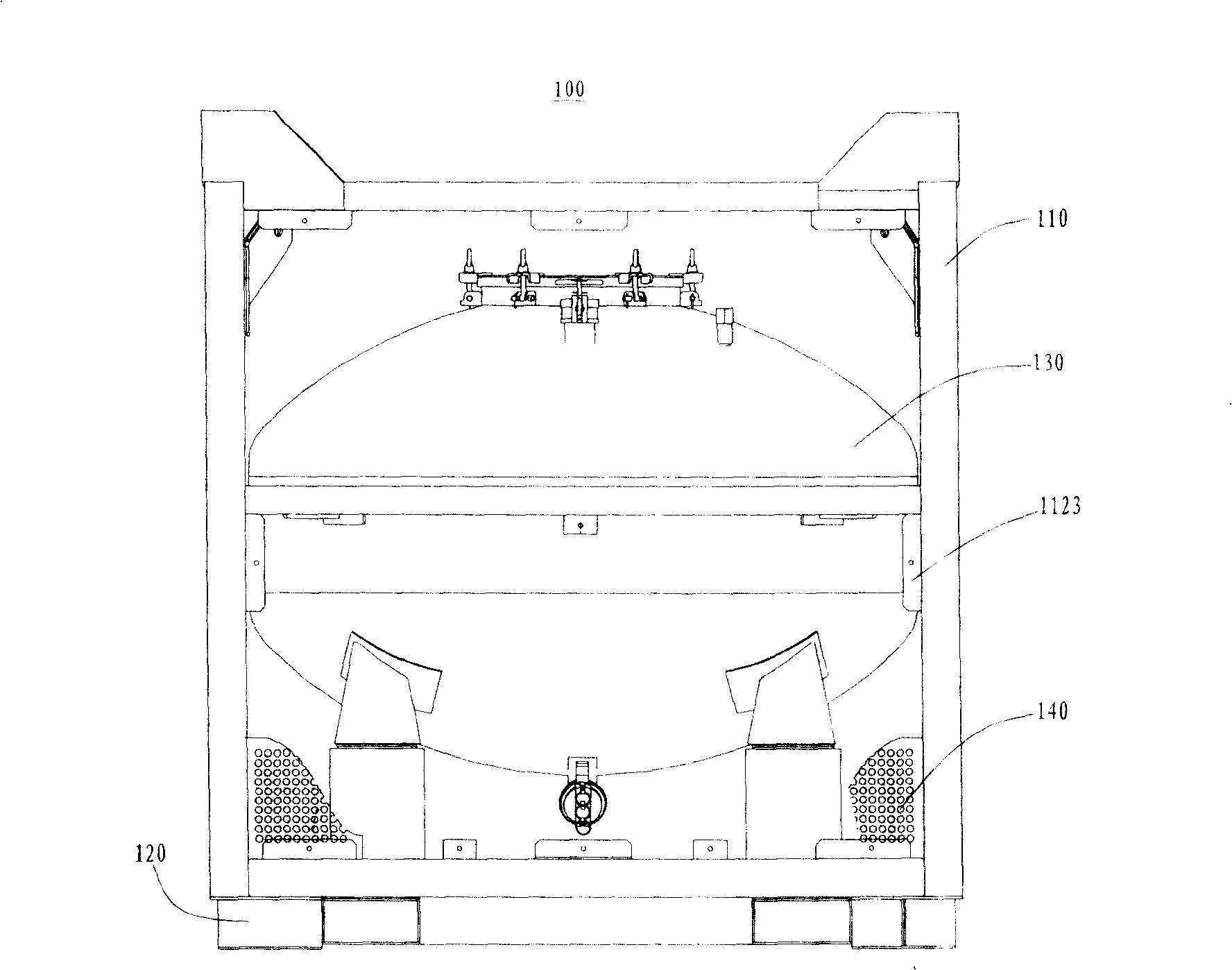

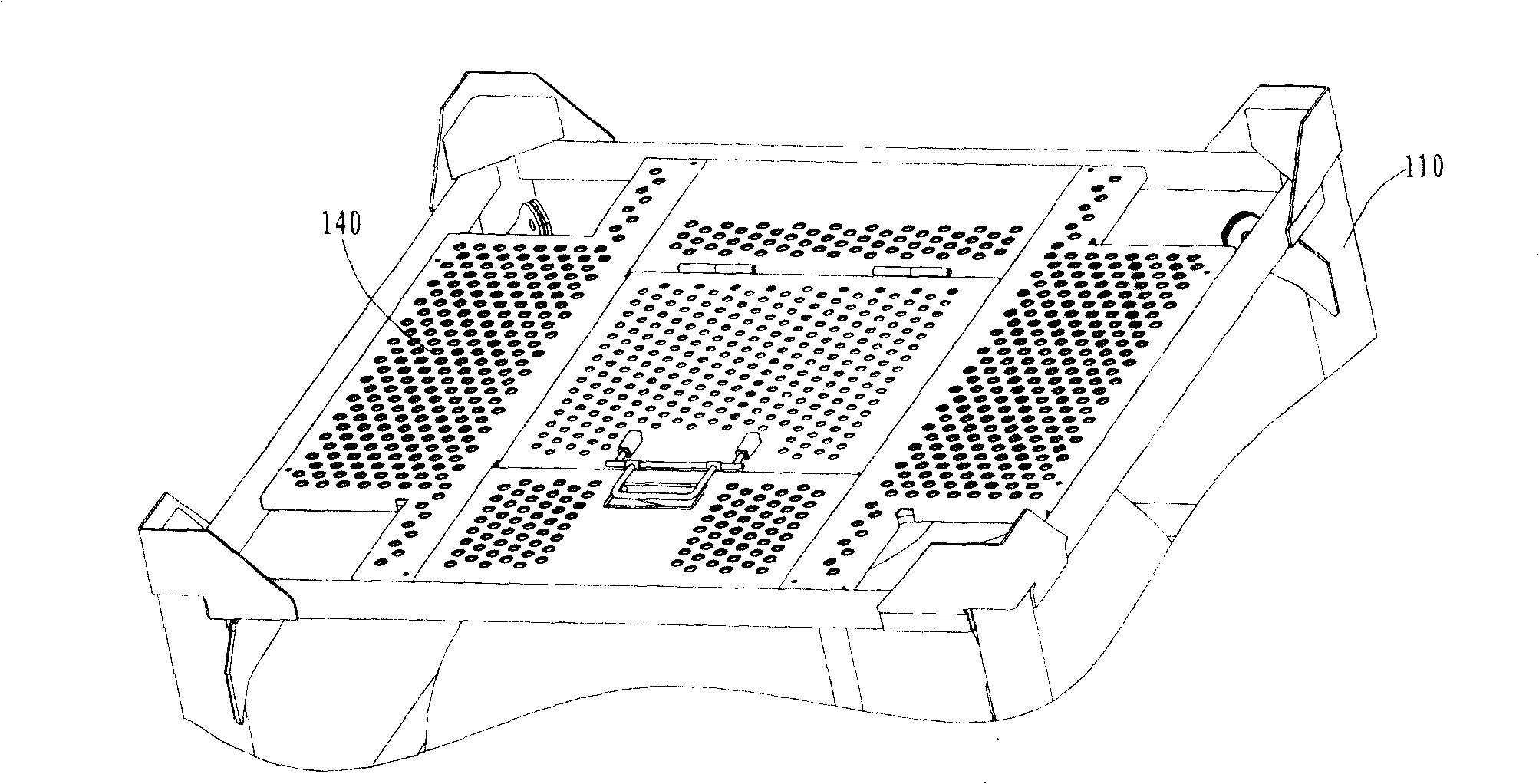

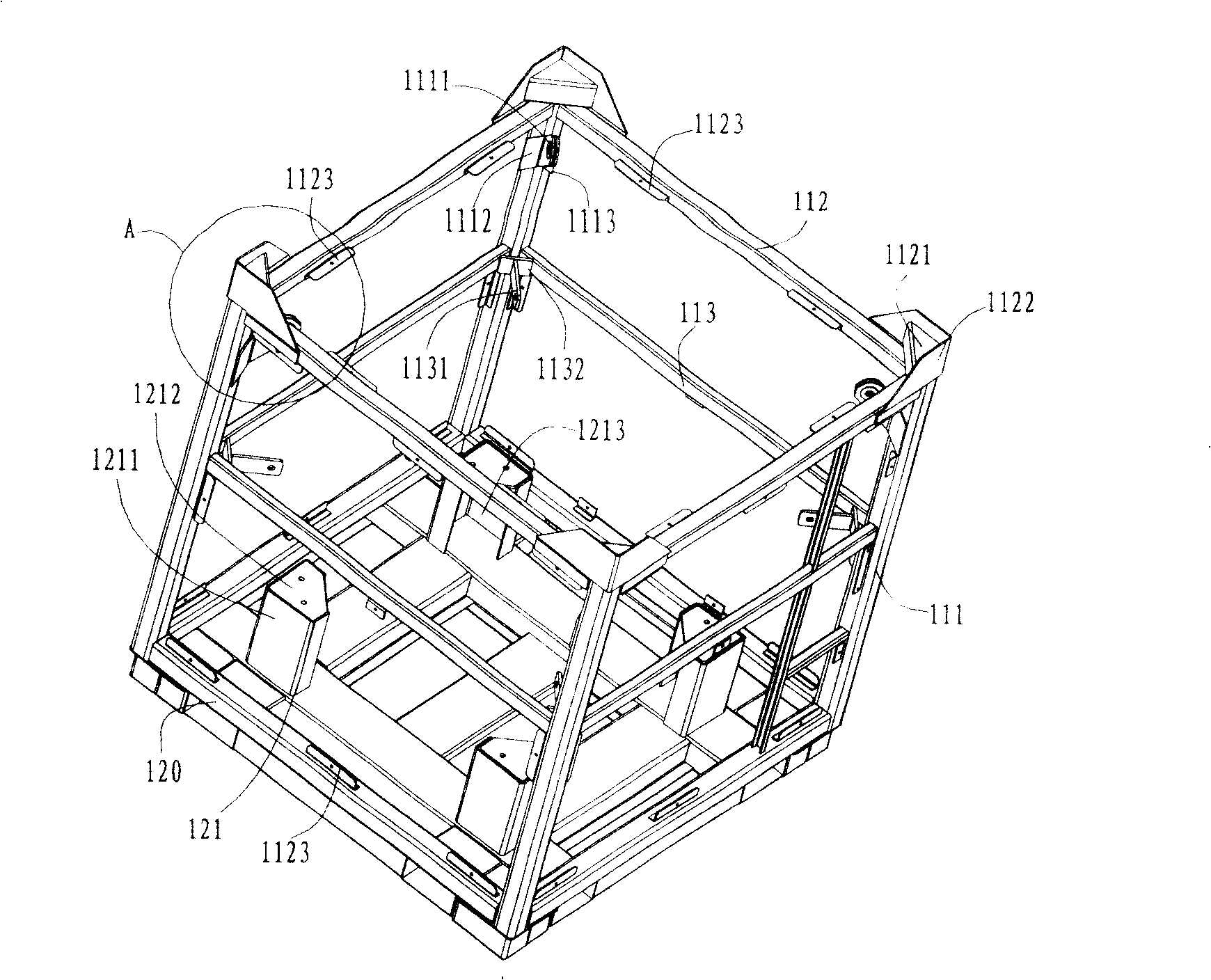

[0041] Such as Figure 1A and Figure 1B As shown, the detachable tank pallet box 100 of the present invention includes: a frame 110; an underframe 120, wherein the frame 110 is arranged on the underframe 120 to form an integral frame; a cylinder 130, which is detachably arranged On the bottom frame 120, and is defined inside the frame 110; and, the protective plate 140 with holes is arranged on the four sides and the top of the frame 110 for protecting the cylinder 130, preferably, the frame 110 It is made of common metals such as carbon steel, and the cylinder body 130 is made of corrosion-resistant metals such as stainless steel, so that the manufacturing cost of the tank pallet box 100 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com