Chemical water pump

A water pump and chemical technology, which is applied in the field of centrifugal chemical water pumps, can solve the problems of large input power, high energy consumption, and small output pressure (lift), and achieve the effect of large load, low energy consumption, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

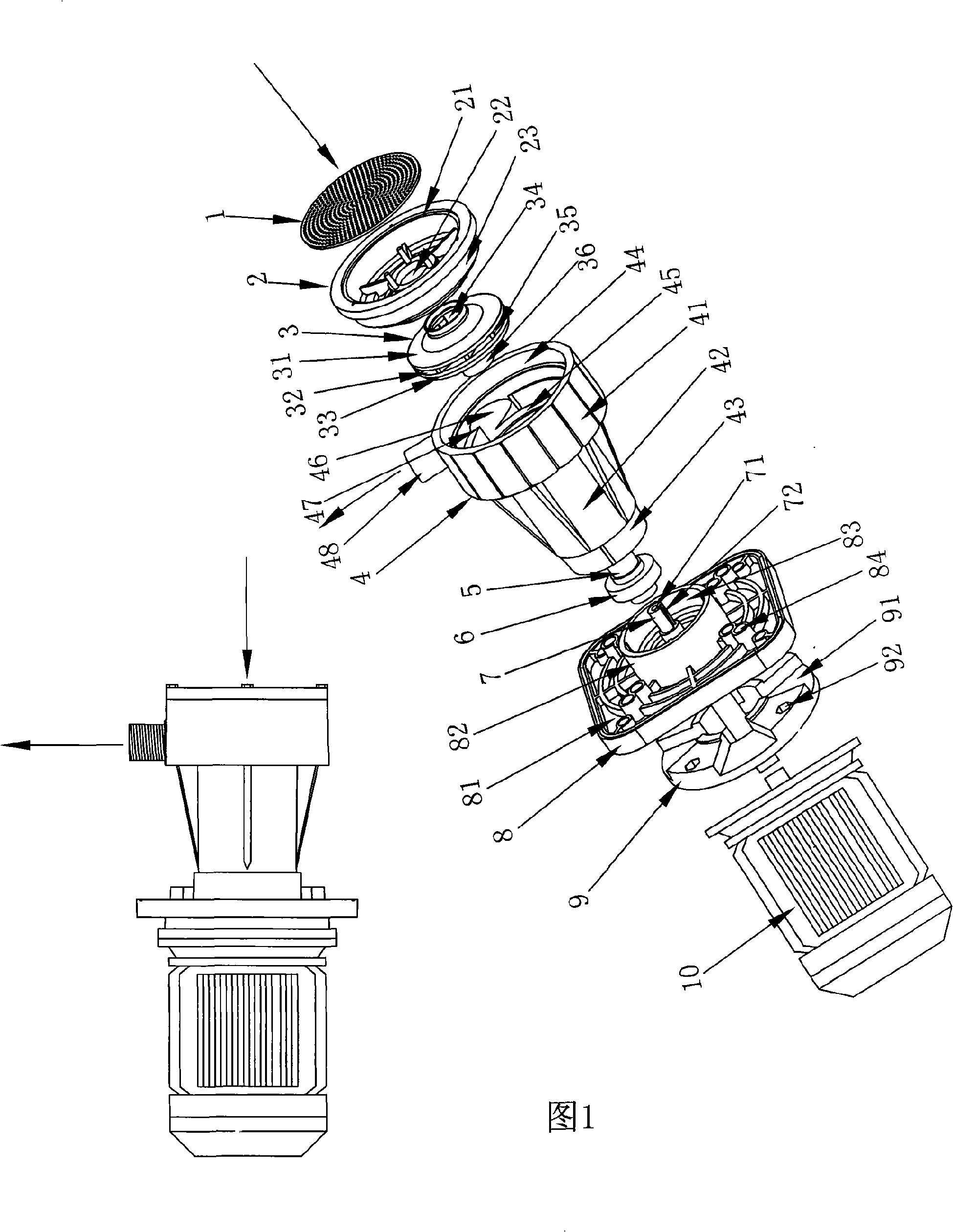

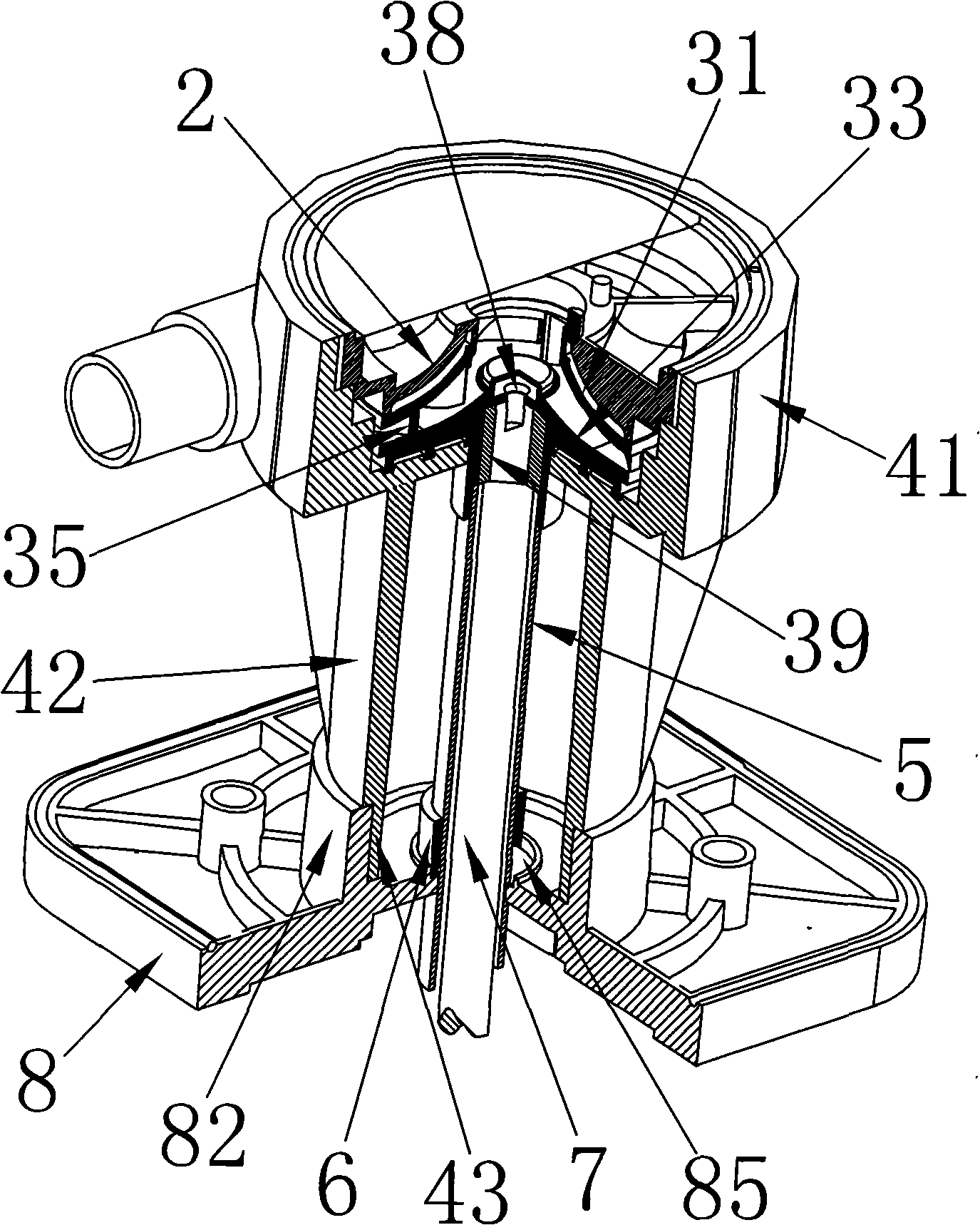

[0035] Please refer to Figure 1 to Figure 5 , a centrifugal chemical water pump comprising a filter screen 1, a pump cover 2, an impeller 3, a pump cavity 4, a motor shaft sleeve 5, a seal ring 6, a motor shaft 7, a pump base 8, a method Blue plate 9, a motor 10.

[0036] The pump base 8 includes a bottom plate 81 , a convex annular outer wall surface 82 on the bottom plate, a convex inverted conical inner wall surface 83 on the bottom plate, several screw holes 84 , and a first motor shaft hole 85 .

[0037] The pump base 8 also includes a flange 9, which includes a set of evenly distributed grooves 91 for ventilation and a set of screw holes 92 for connecting the motor.

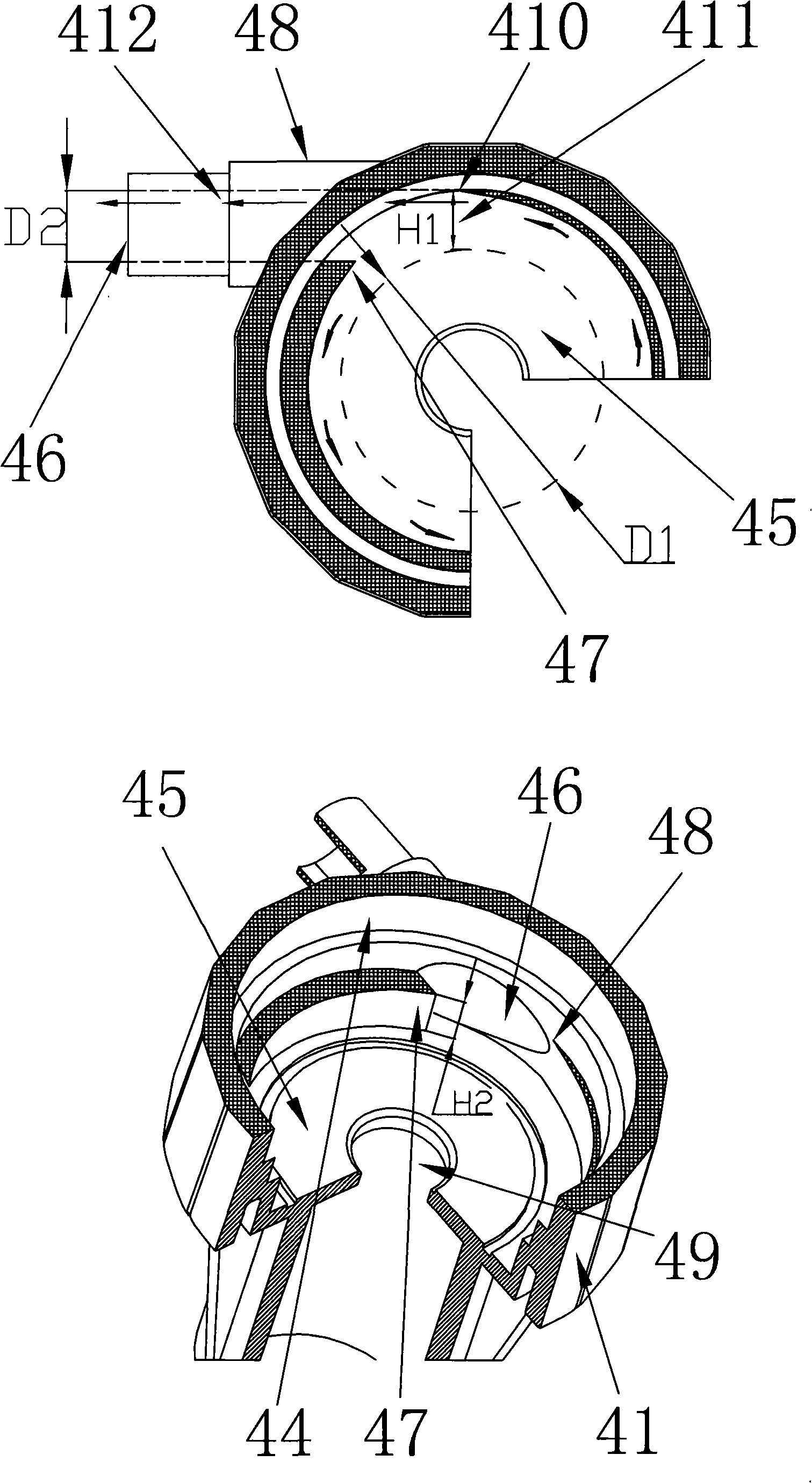

[0038] The pump chamber 4 includes an annular upper shell 41 , an annular lower shell 42 , and an outer conical wall 43 of the annular lower shell.

[0039] The annular upper shell 41 includes an annular inner wall 44 , a pump chamber upper shell bottom plate 45 , a water outlet 46 , a water outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com