Method for rapid accurate determination of superelevation reflectance ratio eyeglass

A reflectivity and fast technology, applied in the testing of optical performance, scattering characteristic measurement, etc., can solve the problems of time-consuming and laborious debugging, low measurement accuracy, etc., and achieve the effect of reducing adjustment difficulty and absolute error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

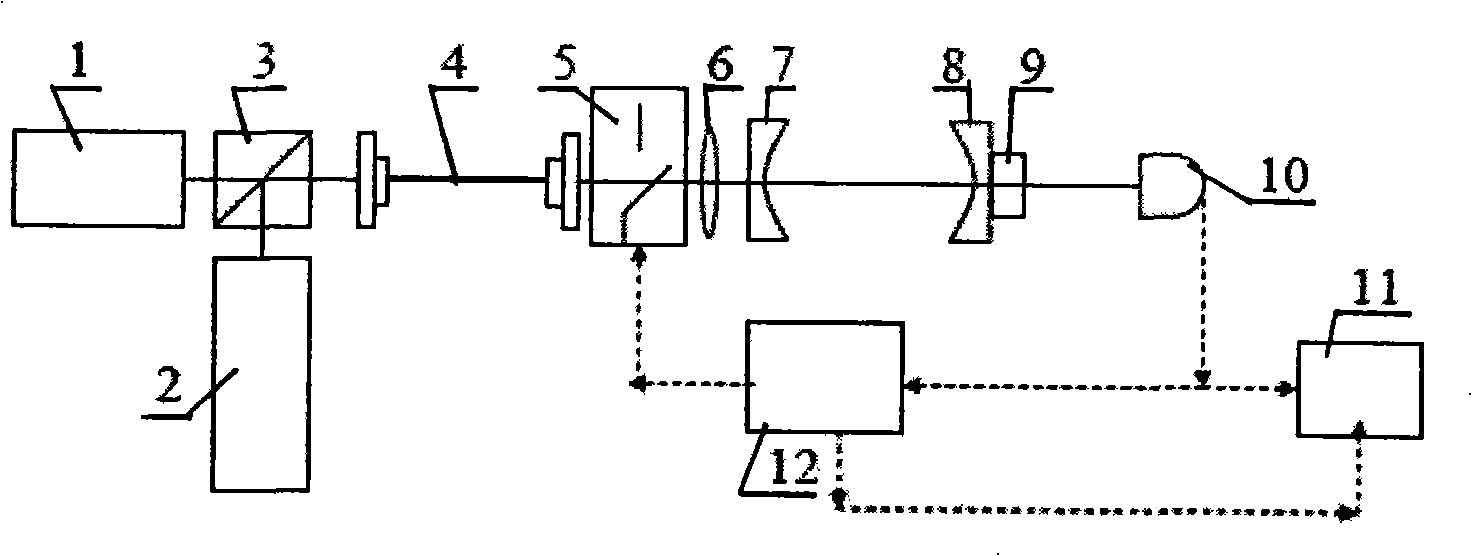

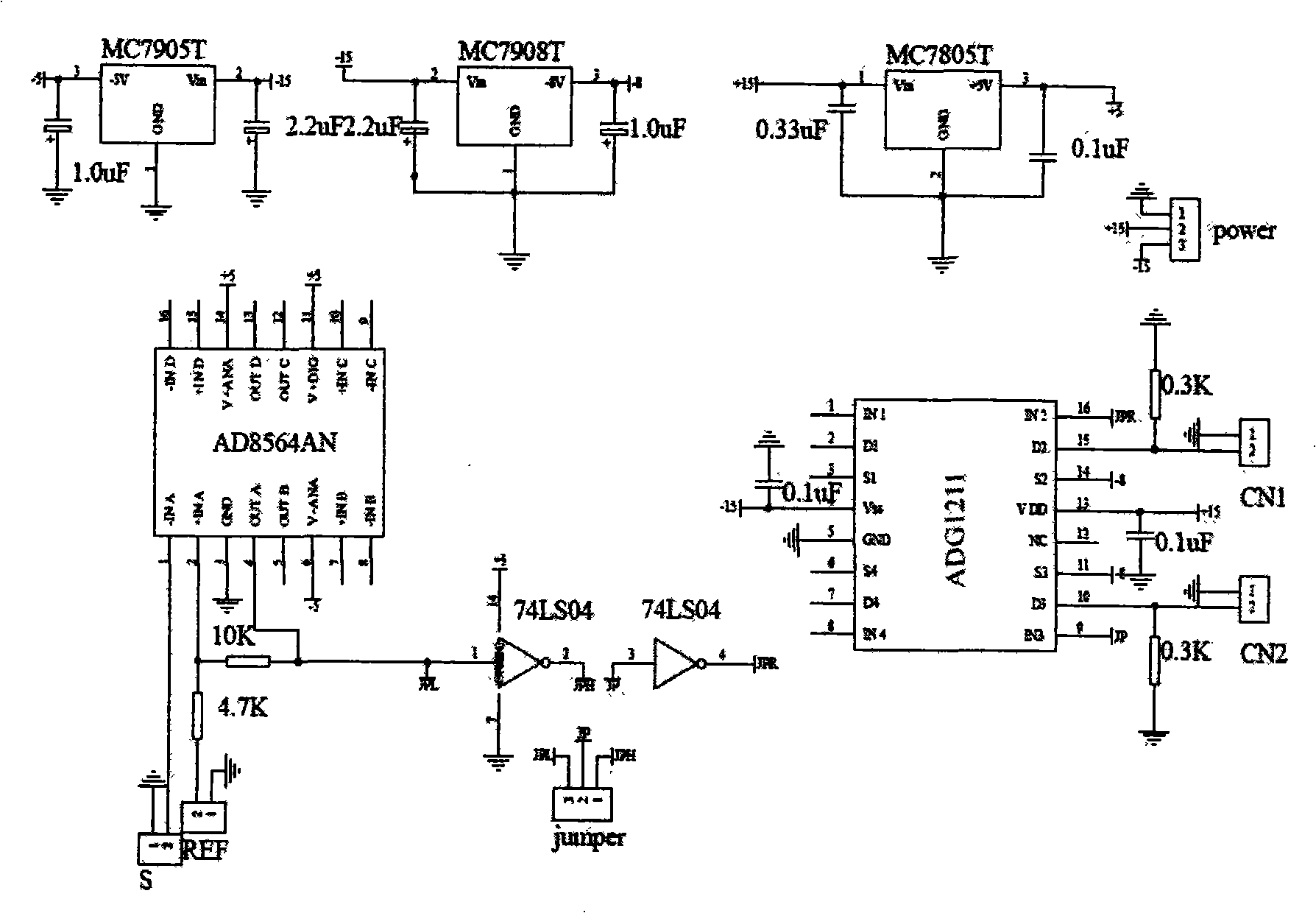

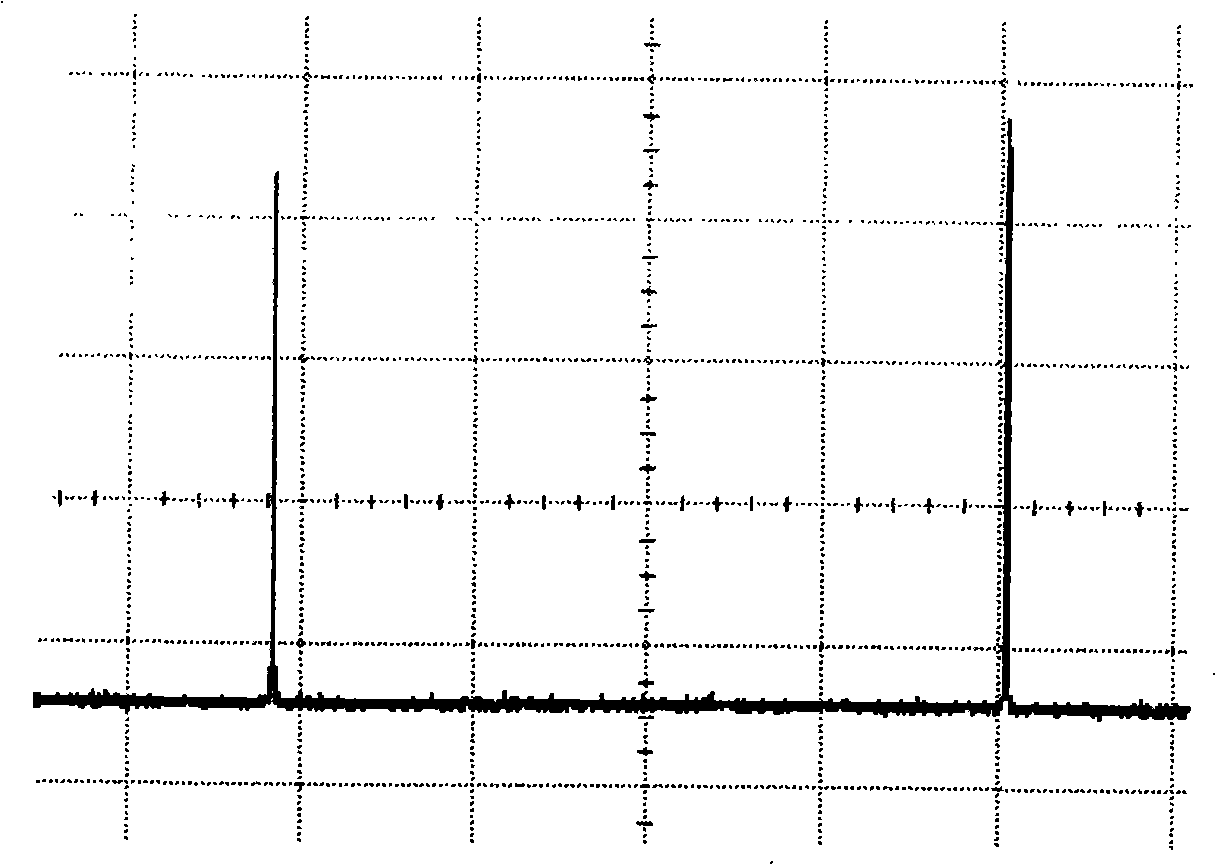

[0022]The method for quickly and accurately measuring ultra-high reflectivity lenses is realized by the following steps: (1) construct an optical cavity (also known as Fapoli-Perot or F-P cavity) including two cavity mirrors, one of the two cavity mirrors is used as a calibration moving plate 8 is placed on the piezoelectric ceramic 9, and the other is used as the static piece 7 to be measured; a matching lens 6 is set at the incident end of the optical cavity, and a fast photodetector 10 is set at the transmission end of the optical cavity; the output end of the fast photodetector is connected to the The oscilloscope 11 is connected to the signal input end of a comparison switch circuit 12, and the optical path fast controllable switch 5 is arranged on the incident light path of the optical cavity, and the controlled end of the light path fast controllable switch is connected to the output end of the comparison switch circuit. In specific implementation, when constructing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com