Quasi continuous green light laser with two-chamber interconnect V type structure one-way overlap output

A quasi-continuous, laser technology, applied in the laser field, can solve the problems of thermal lens effect, thermally induced birefringence, high photon number density, high power density, small spot area, and improved pumping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

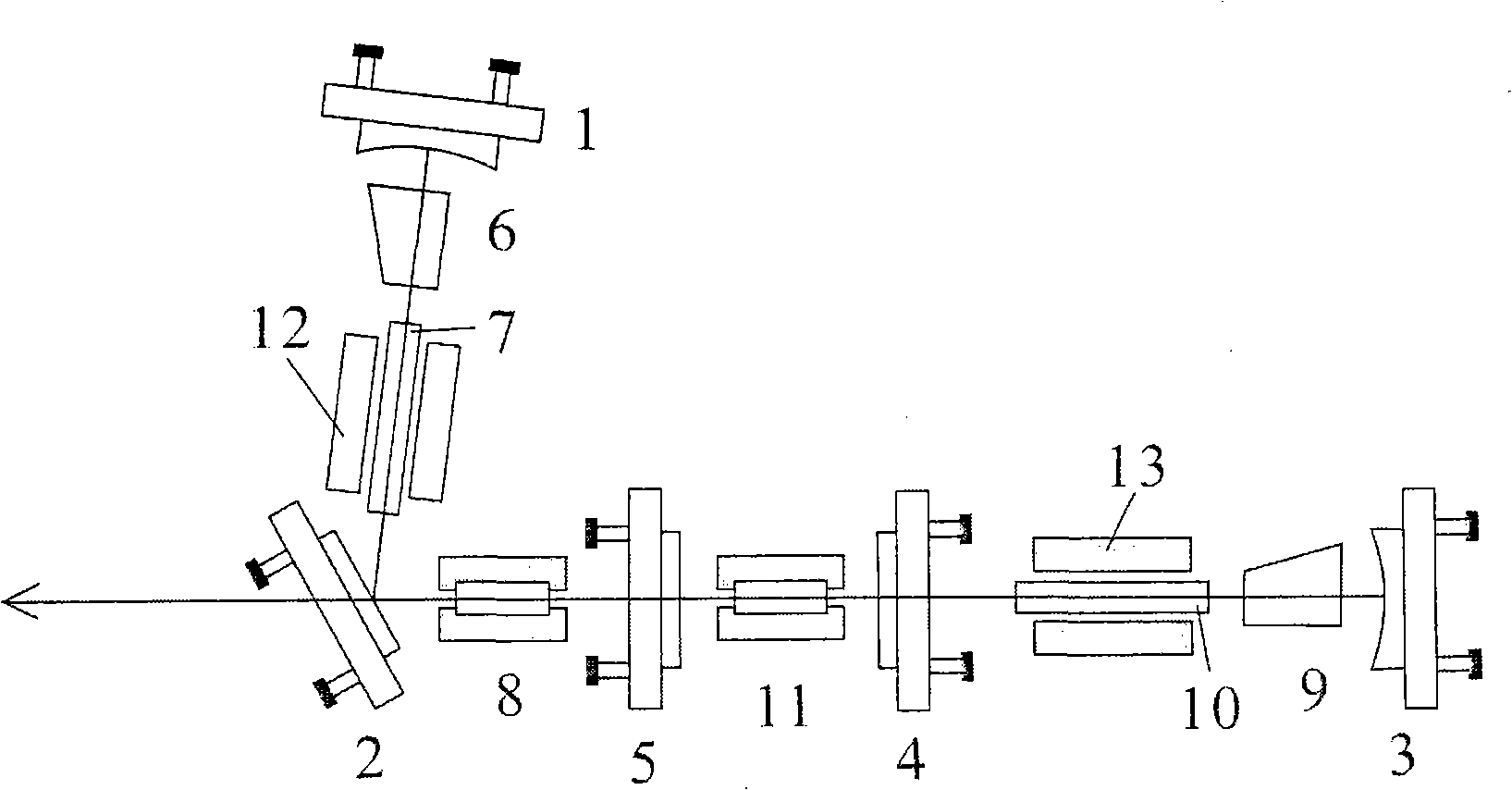

[0025] Accompanying drawing is embodiment of the present invention.

[0026] Below in conjunction with accompanying drawing, content of the present invention will be further described:

[0027] See attached figure 1 As shown, it includes plano-concave total reflection mirrors 1 and 3, and its two laser crystal rods are respectively placed in two parts of the optical path, and the optical components of a part of the optical path are sequentially composed of plano-concave total reflection mirror 1, acousto-optic Q-switching crystal 6, The laser crystal 7 and the high-power semiconductor pump components 12 on both sides of the laser crystal 7 and the plane folded green light output mirror 2 are connected with the adjustment frame to form a flat-concave V-shaped resonant cavity. The direction is followed by a frequency-doubling crystal 8, a full-reverse plane mirror 5, a frequency-doubling crystal 11, a second harmonic mirror 4, a laser crystal 10 and high-power semiconductor pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com