Method and devices for sonicating liquids with low-frequency high energy ultrasound

An ultrasonic, high-energy technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical/physical-chemical nozzle reactors, etc. Expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

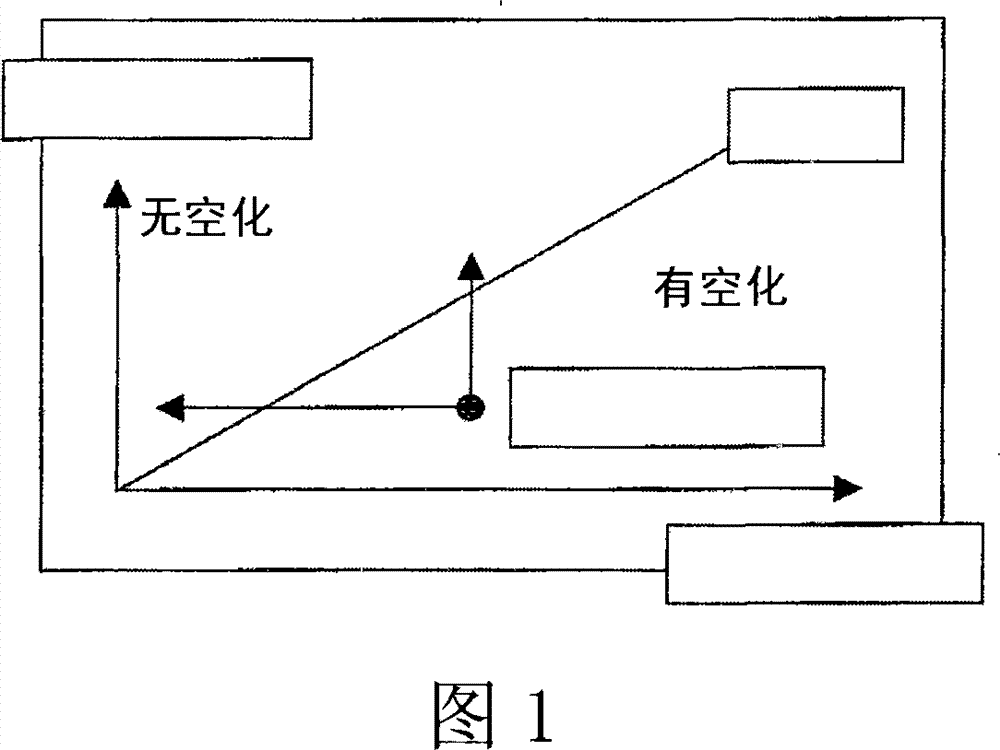

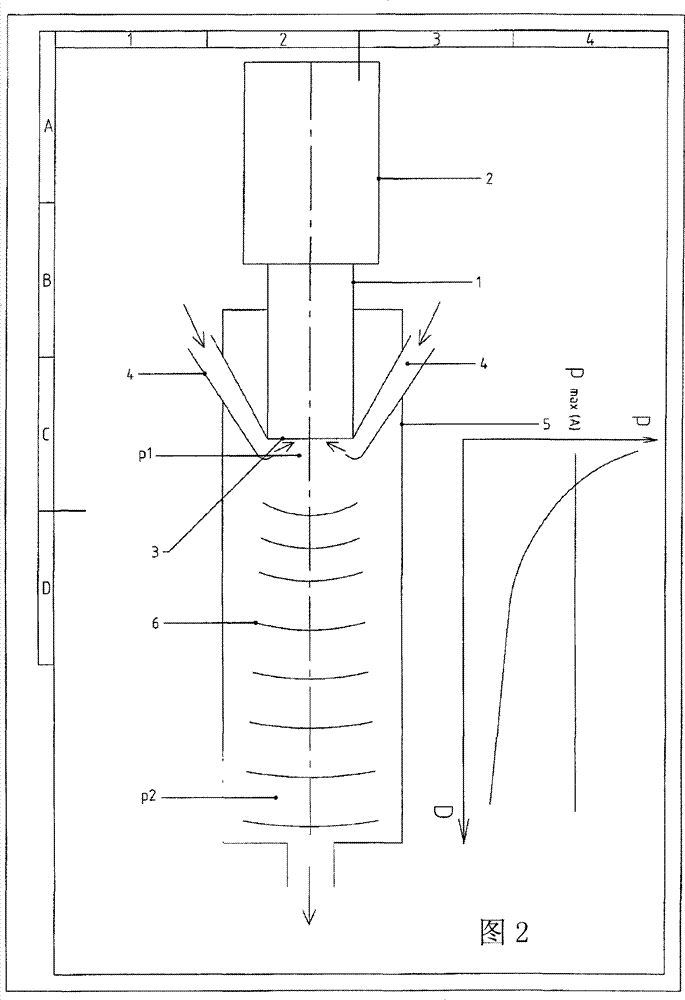

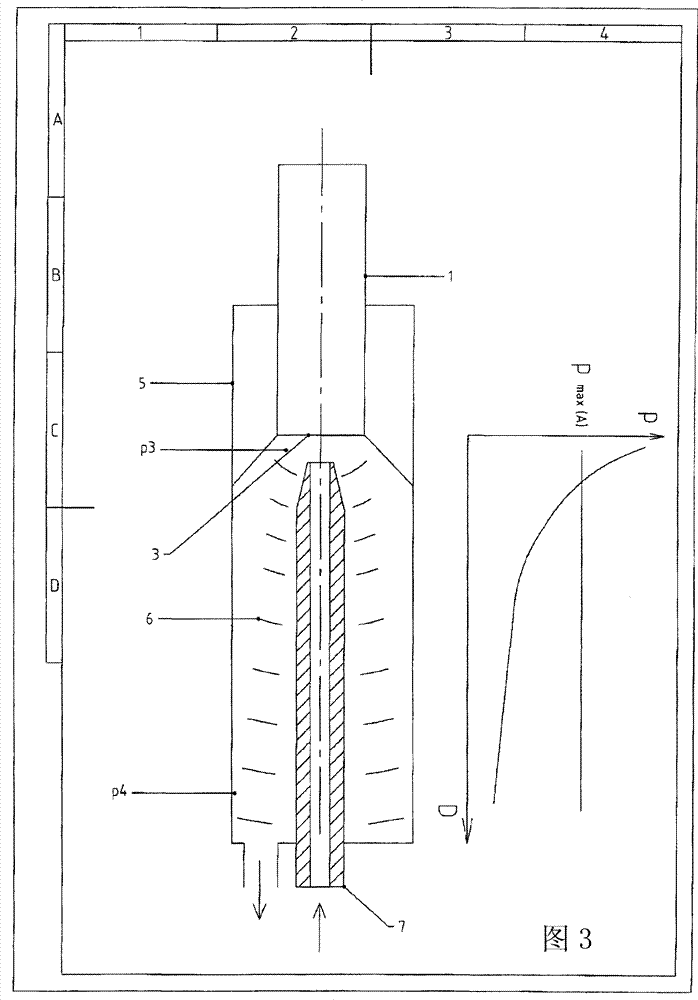

[0031] figure 1 The liquid pressure pmax(A) process is shown, through which the generation of cavitation can be completely suppressed, because when p>pmax(A), the liquid is pressed on the surface of the ultrasonic probe that transmits vibrations, so that local vacuum bubbles cannot appear. In contrast, there is a minimum vibration amplitude Amin(p) for each liquid pressure p below which cavitation cannot occur. The maximum liquid pressure pmax(A) and the minimum vibration amplitude Amin(p) can be determined empirically for different liquids. For example, cavitation erosion or high-frequency ultrasound reflections at the surface of the vibratingly propagating ultrasound probe can be used as measured values. The latter is used to generate vibrations in the megahertz range when cavitation bubbles implode.

[0032] By changing the vibration amplitude A at different distances D from the surface of the ultrasonic probe propagating vibrations according to the present invention, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com