Electrospark forming processing DNC system facing die making system

A molding and mold manufacturing technology, applied in the field of EDM DNC system, can solve the problems of low efficiency, increase production cost, incompatibility of mold manufacturing system, etc., and achieve the effect of ensuring independence and ensuring mutual connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

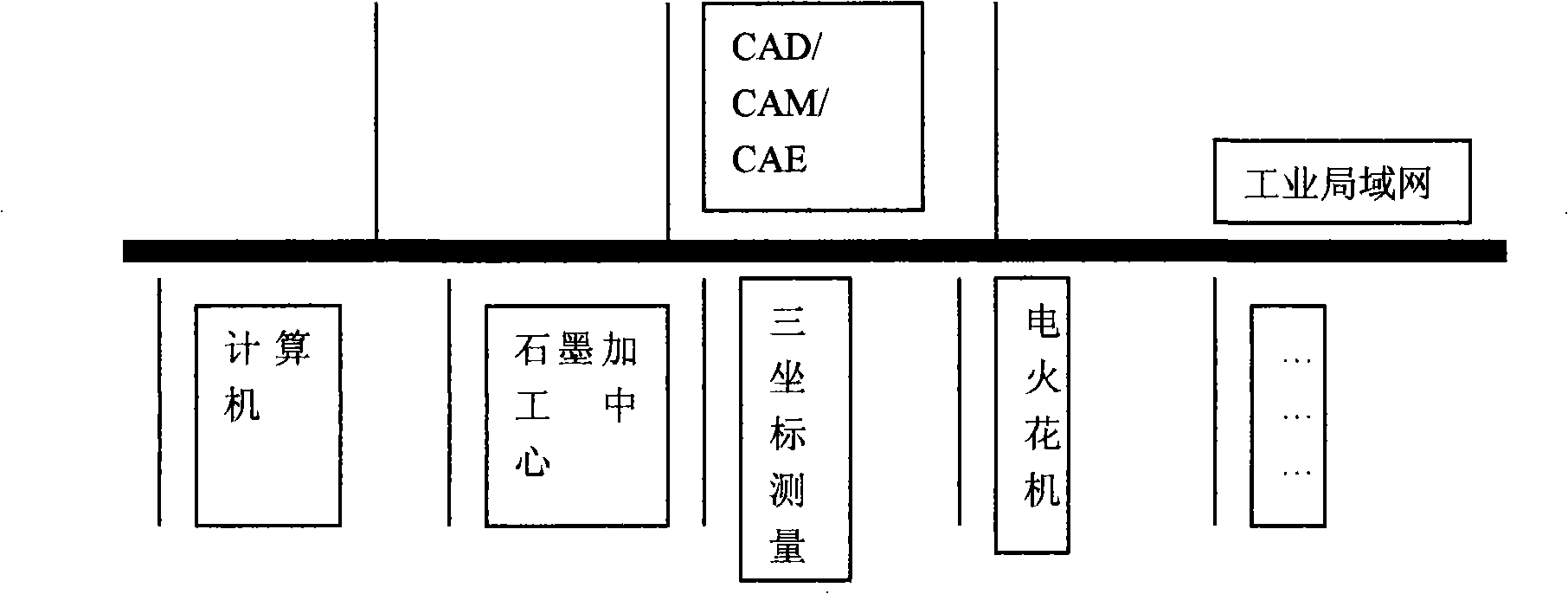

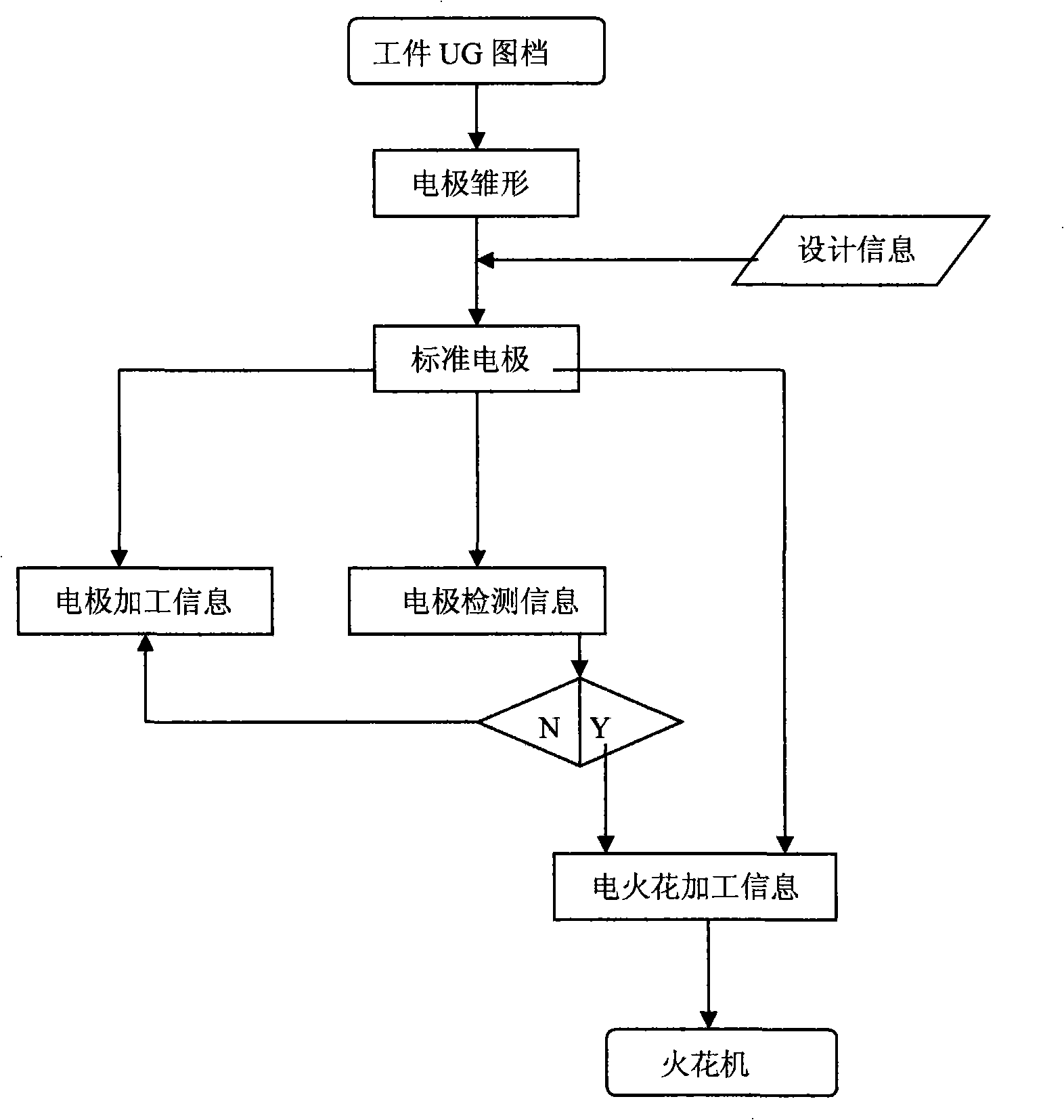

[0016] Such as figure 1 As shown, the EDM DNC system oriented to the mold manufacturing system is a powerful processing system that makes full use of the CNC machine tool, the positioning system (EROWA), the modern testing equipment CMM (three-coordinate detector) and the industrial local area network for organic integration. Control System. The system has advanced CAD / CAM / CAE software UG, and correspondingly developed electrode generation module, program generation module, point acquisition module, etc., which can quickly and accurately design high-quality electrodes, corresponding to various numerical control equipment, and develop EDMDNC programming software, three-coordinate measuring point module, and graphite processing programming module have been installed, thereby improving the efficiency of EDM, shortening the mold manufacturing cycle, realizing the automation of EDM, and filling the gap in the mold industry where EDM is difficult to automate. A big blank.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com