Modeling method for alkylarene liquid phase oxidation dynamics mechanism model

A liquid-phase oxidation and mechanism model technology, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problems of inability to establish, the complexity of catalysts affecting the reaction and inability to detect free radicals and molecular products, etc. The effect of reducing estimation difficulty, simplifying chemical reaction models, and good practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

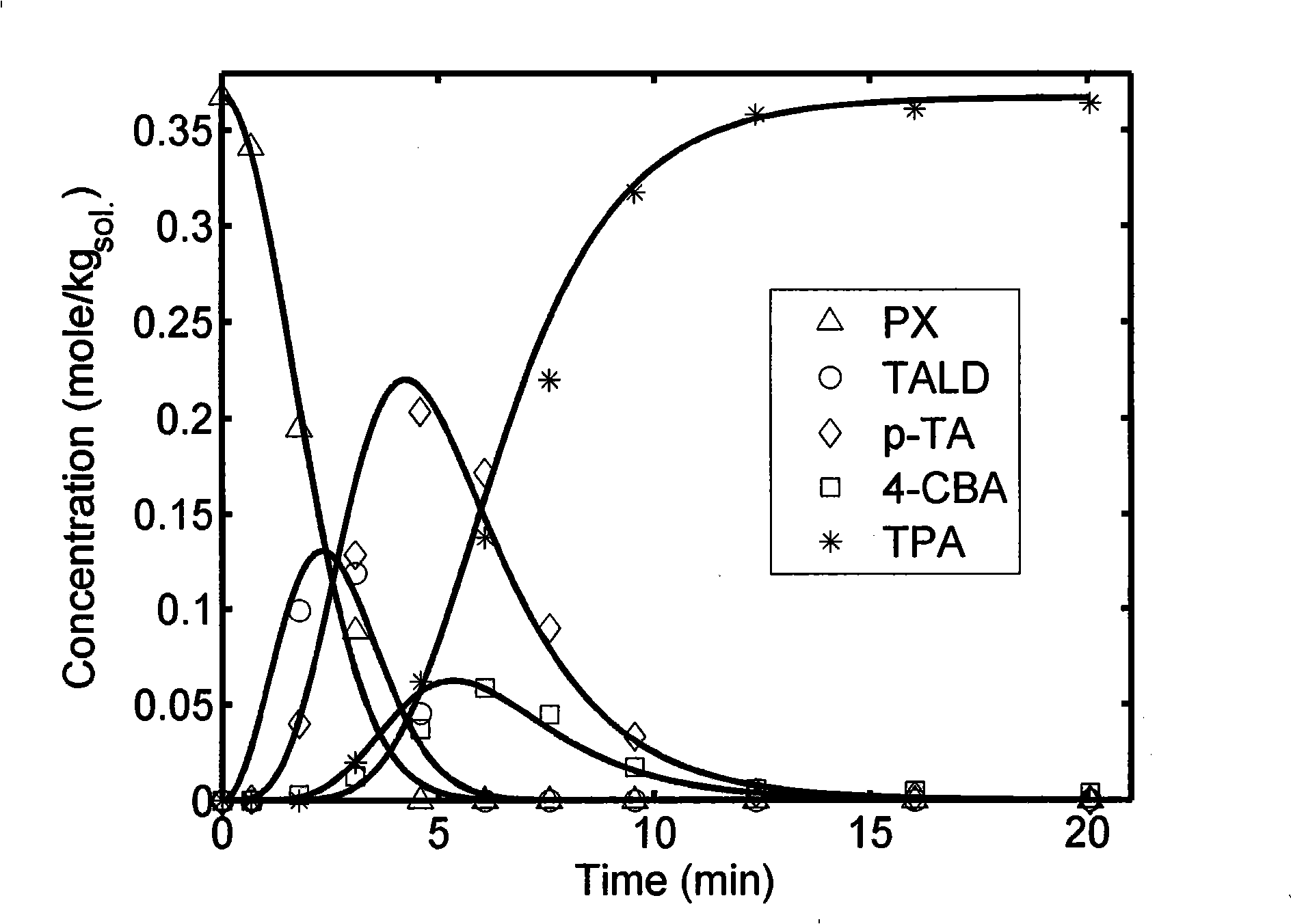

[0028] The following example takes the reaction process of PX liquid-phase oxidation to TPA catalyzed by the catalyst Co / Mn / Br as an example to illustrate the modeling method of the liquid-phase oxidation kinetic model of alkyl aromatic hydrocarbons.

[0029] 1. Analyze the PX liquid-phase oxidation process and extract the chemical reaction components involved.

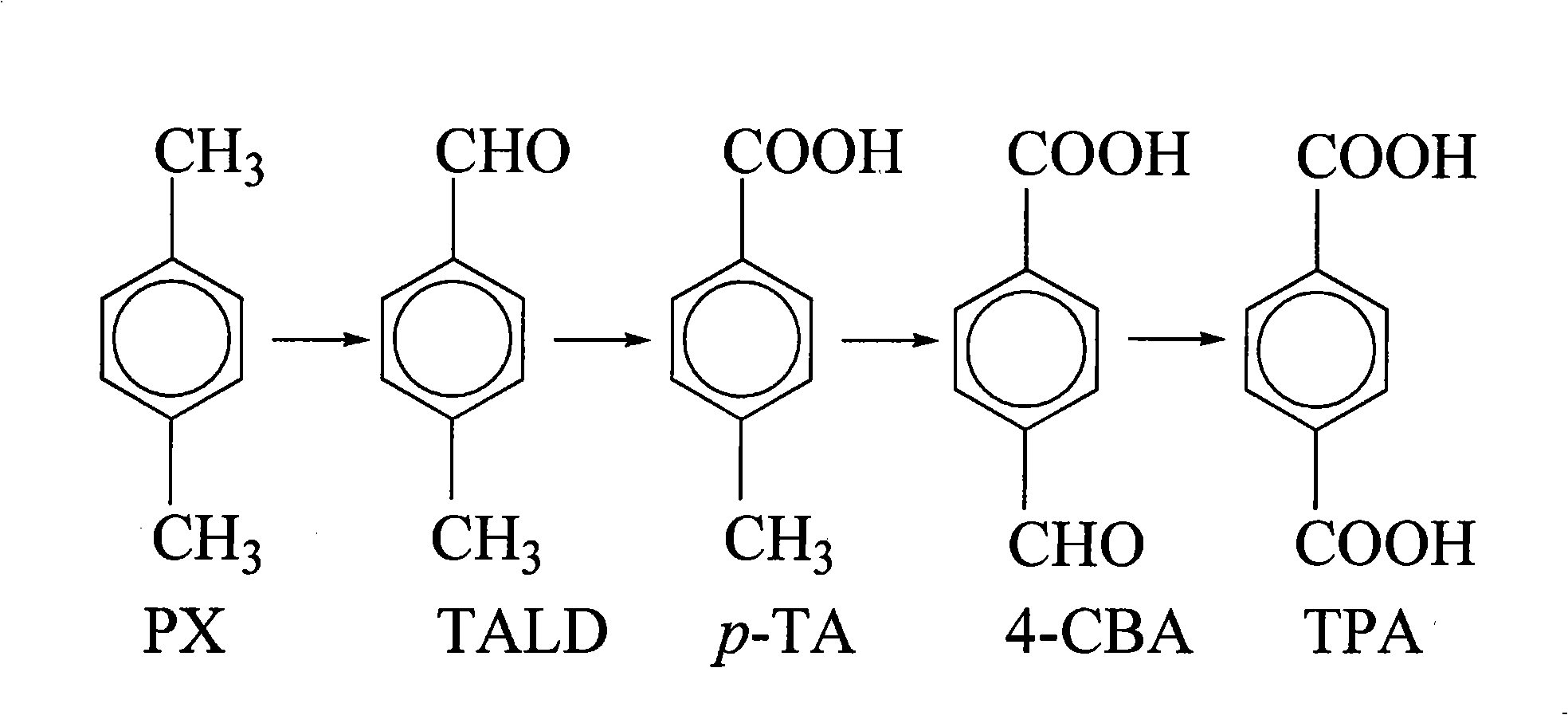

[0030] Please refer to figure 1 , that is, the process path of PX liquid phase oxidation. First, the methyl group on the benzene ring of the reactant xylene generates an aldehyde, and the aldehyde group subsequently generates a carboxylic acid, and the oxidation of the second methyl group occurs after the first methyl group is oxidized to a carboxyl group, so the reaction process The intermediate products generated in the process include p-tolualdehyde (TALD, Tolualdehyde), p-toluic acid (p-T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com