Steel-smelting converter gravitation dry method dust-removing and residual heat reclaiming device

A waste heat recovery device and dry dust removal technology, which is applied in the field of converter steelmaking dust removal and waste heat recovery devices, energy saving and emission reduction devices, can solve the problems of poor dust removal effect, high cost, complex structure, etc., and achieve good dust removal effect and easy installation Convenience, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

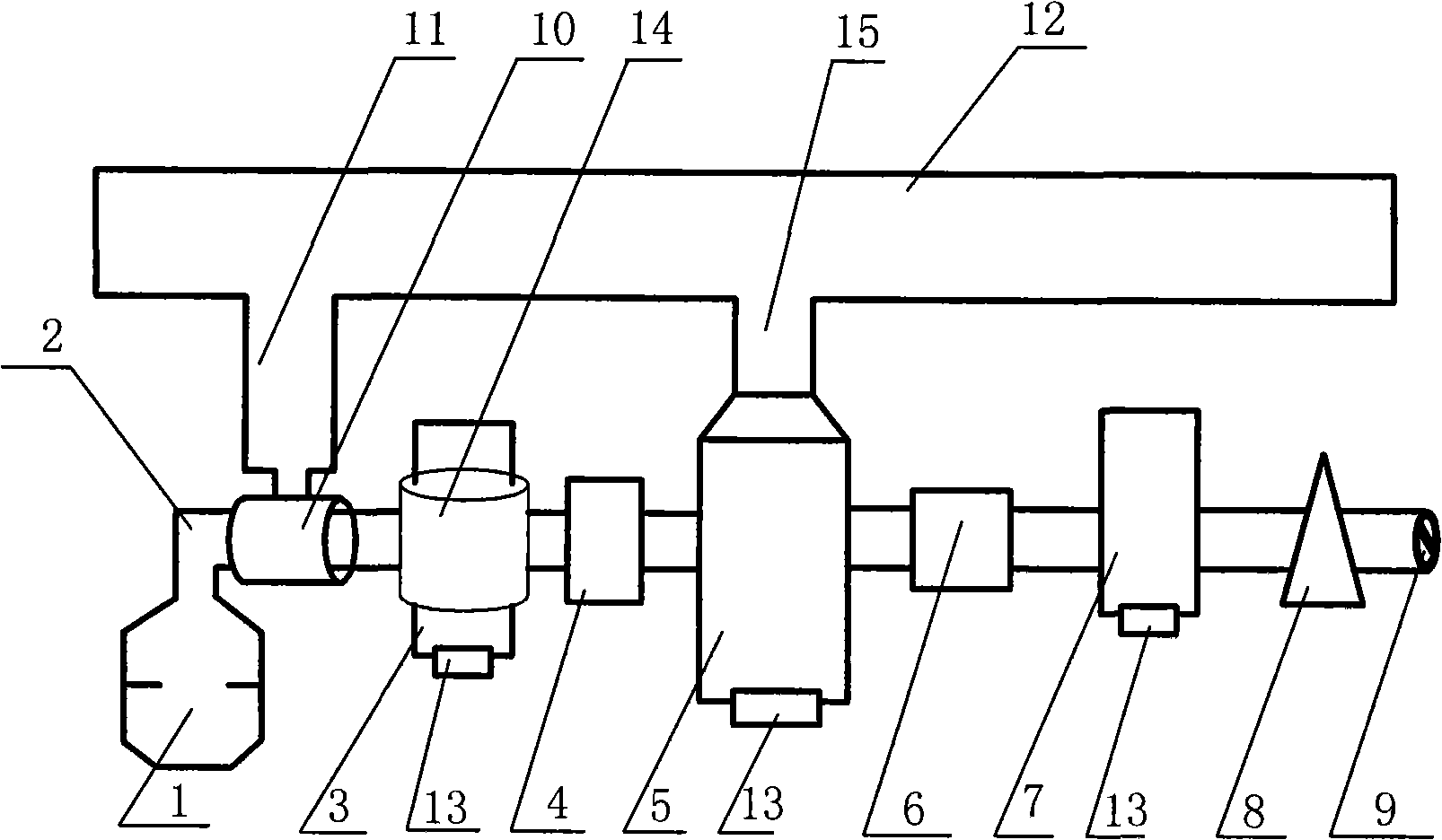

[0012] In order to enable those skilled in the art to clearly understand the technical scheme of the present invention, it will now be further described in detail in conjunction with the accompanying drawings:

[0013] The steelmaking converter gravity dry dust removal and waste heat recovery device of the present invention, such as figure 1 , including the converter 1, the converter 1 is connected to the gravity dust collector 3 through the flue 2, the gravity dust collector 3 is connected to the corrugated compensator 4 through the flue 2, the corrugated compensator 4 is connected to the dust removal boiler 5 through the flue 2, and the dust removal boiler 5 The flue 2 is connected to the heat pipe exchanger 6, the heat exchanger 6 is connected to the bag filter 7 through the flue 2, the bag filter 7 is connected to the flue gas spraying device 8 through the flue 2, and the flue gas spraying device 8 passes through The flue 2 is connected to the induced draft fan 9, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com