Sizing machine sizing ratio on-line checking and controlling device

A control device and technology of a sizing machine, which is applied in the directions of textile processing machine accessories, textile material inspection, and textile material processing equipment configuration, etc. and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

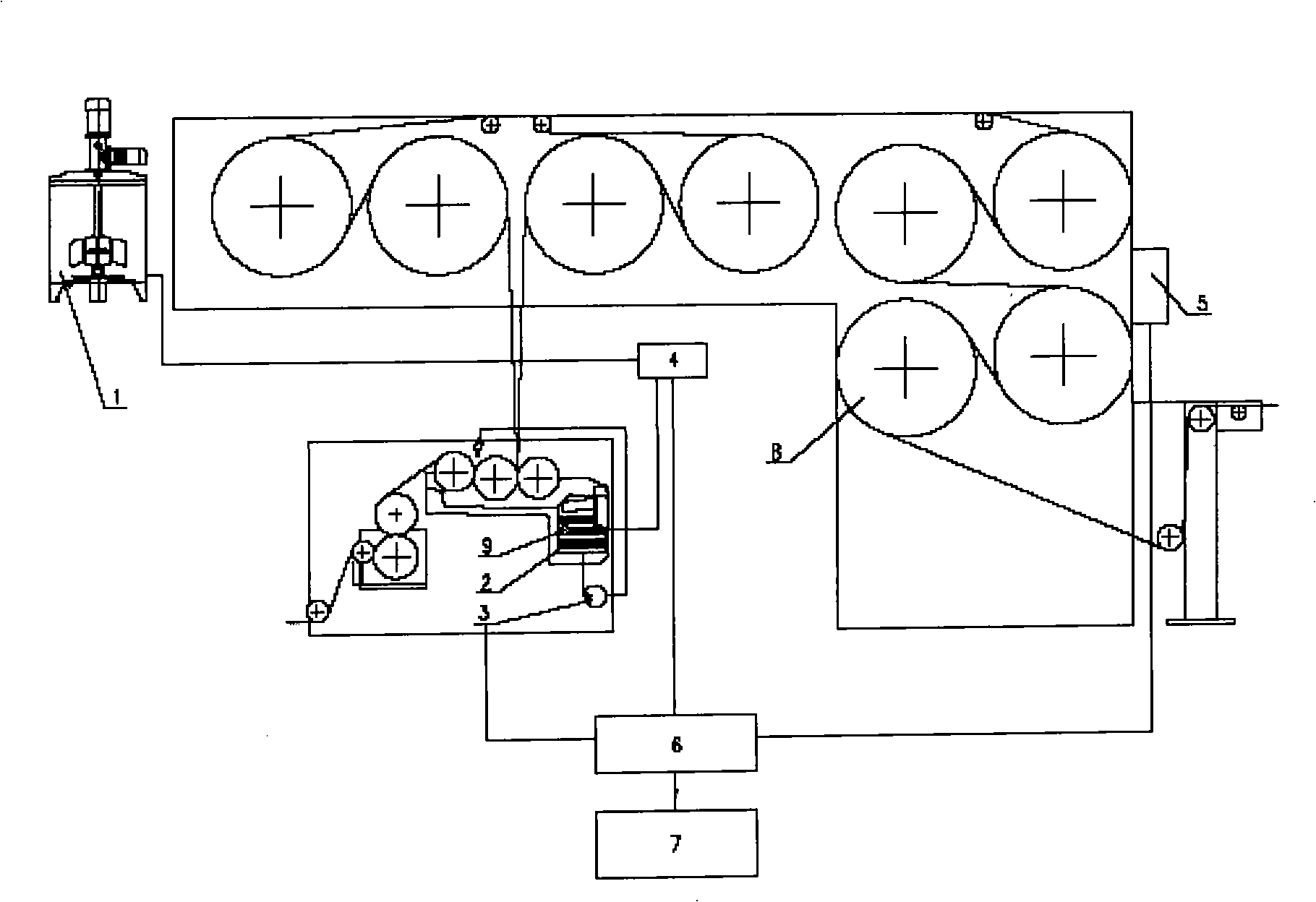

[0010] The online detection and control device for sizing rate of the sizing machine is mainly composed of a flow meter, a concentration detector, a moisture meter, and an industrial computer. A digital flow meter 4 is installed between the sizing barrel 1 and the preheating pulp box 2. A concentration detector 3 is installed on the lower pipeline of the slurry box 2, and a humidity meter 5 is installed at the outlet of the drying room 8, and the output ports of the flowmeter, the concentration detector, and the humidity meter are connected with an industrial computer 6.

[0011] A ball float 9 is housed in the above-mentioned preheating pulp box 2.

[0012] In the warp sizing process, the upper and lower limit switches controlled by a floating ball in the preheating size box 2 control the size from the pulping tank 1 into the preheating pulping tank 2, so as to ensure the normal supply of the size in the sizing process; the pulping tank A digital flowmeter 4 is installed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com