Ultra-high tensile steel vehicle door anti-collision joist and method of manufacture

A technology of ultra-high-strength steel and automobile doors, which is applied in the field of ultra-high-strength steel automobile door anti-collision beams and its manufacturing, can solve the problems of difficult implementation and large investment in equipment, and achieve the effect of avoiding cracking and ensuring accuracy and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

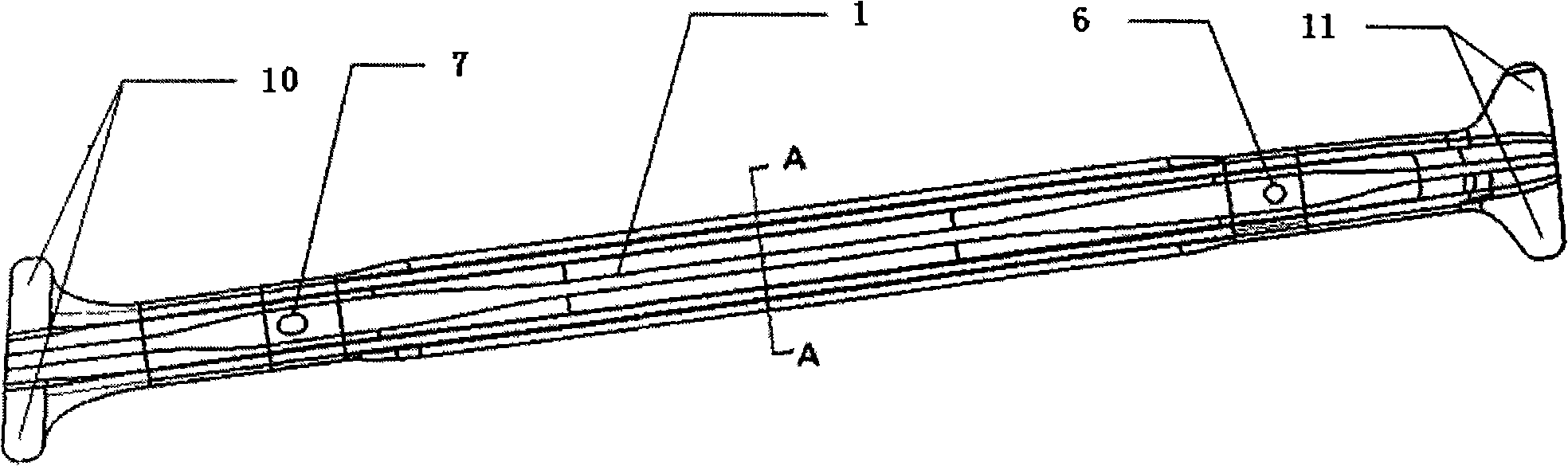

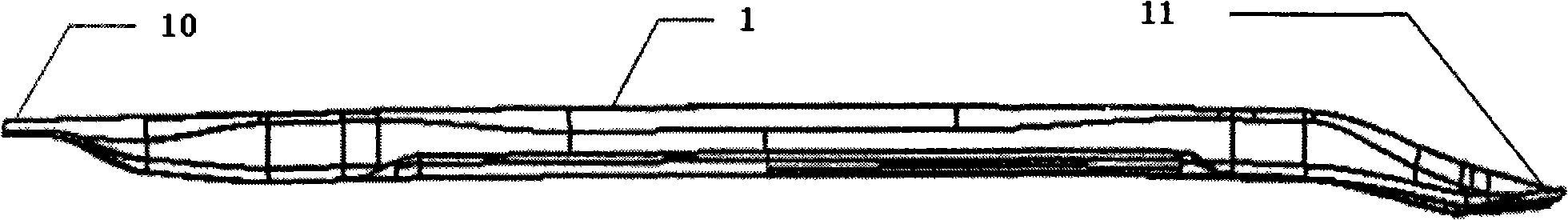

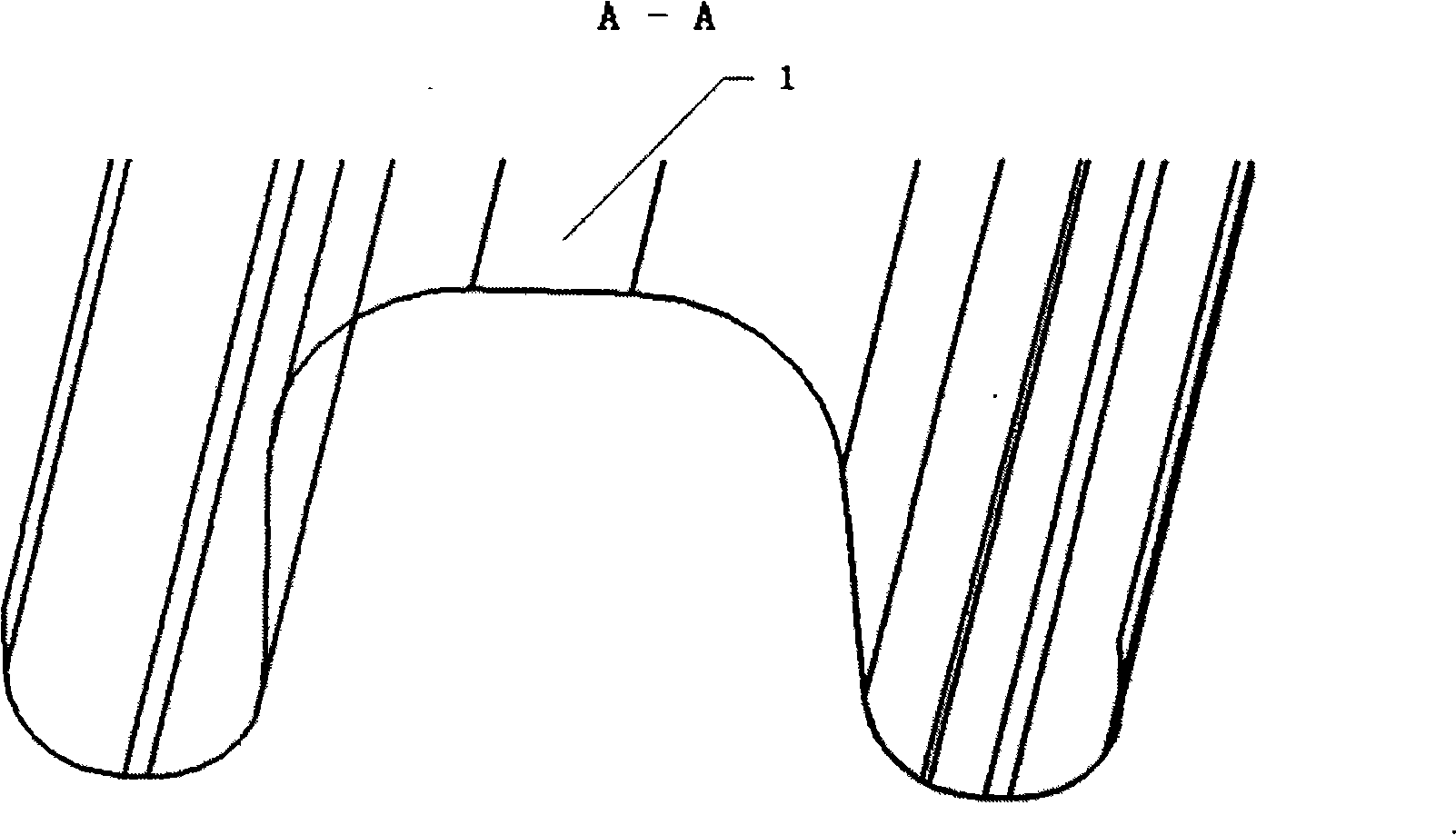

[0024] see figure 1 , figure 2 with image 3 , the beam body 1 of the ultra-high-strength steel automobile door anti-collision beam according to the present invention is a steel plate formed integral member with a "U" shape in cross section, the beam body is in a slender shape, and a main positioning device is arranged on the right part of the beam body The hole 6 and the left part are provided with auxiliary positioning holes 7, and the left and right ends of the beam body are respectively provided with welding overlapping surfaces 10 and 11;

[0025] The beam body 1 is made of ultra-high-strength steel, and its composition contains C=0.11%, Si=0.20%, Mn=1.6%, P≤0.015%, S≤0.002%, Al=0.04%, Nb≤0.015%, Its yield strength is greater than 950Mpa, and its tensile strength is greater than 1200Mpa. The selected material is Docol 1200M (produced by SSAB Company in Sweden), which belongs to ultra-high strength steel plate.

[0026] see Figure 4 , the ultra-high-strength steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com