Oil-free fluid machine having two or more rotors

A fluid machinery, rotor housing technology, applied in the direction of rotary piston machinery, mechanical equipment, liquid fuel engines, etc., can solve the problems of plastic gear damage, reduce working life and other problems, achieve balanced torque transmission, prolong working life, easy to use. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the present invention will be described with reference to the drawings. However, it should be pointed out that unless otherwise specified, dimensions, materials, relative positions, and components in the embodiments should be interpreted as illustrative only, and not as limiting the protection scope of the present invention.

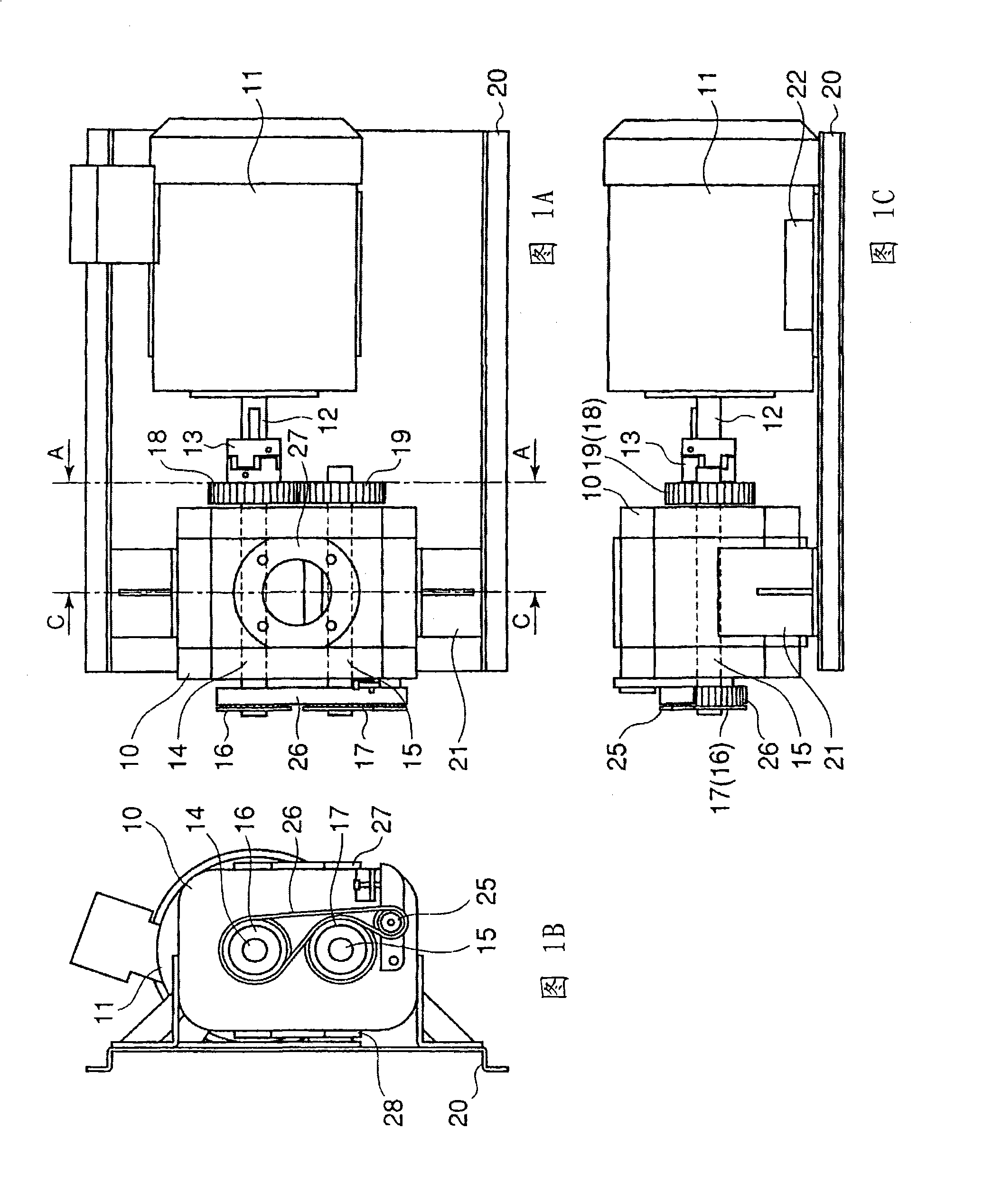

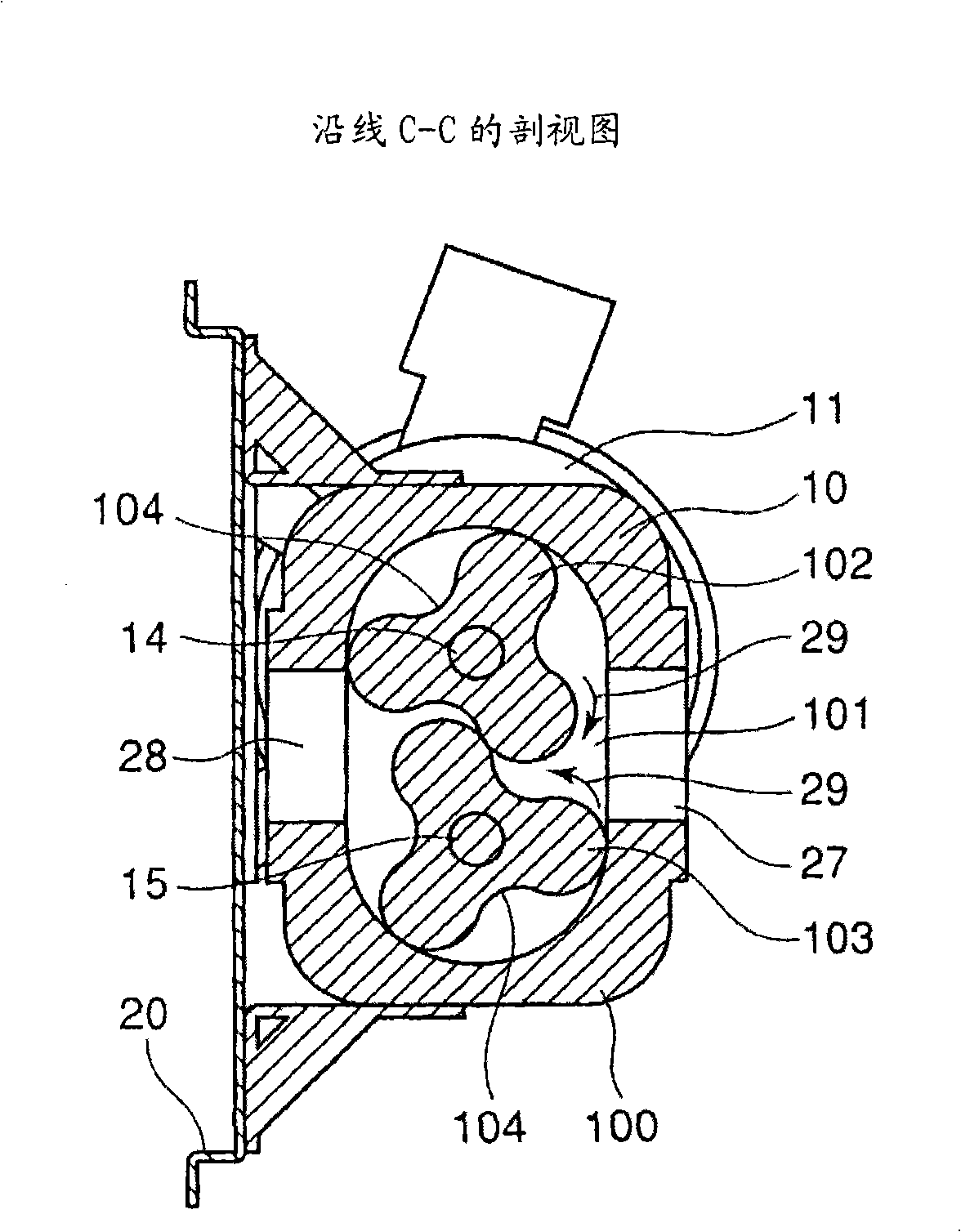

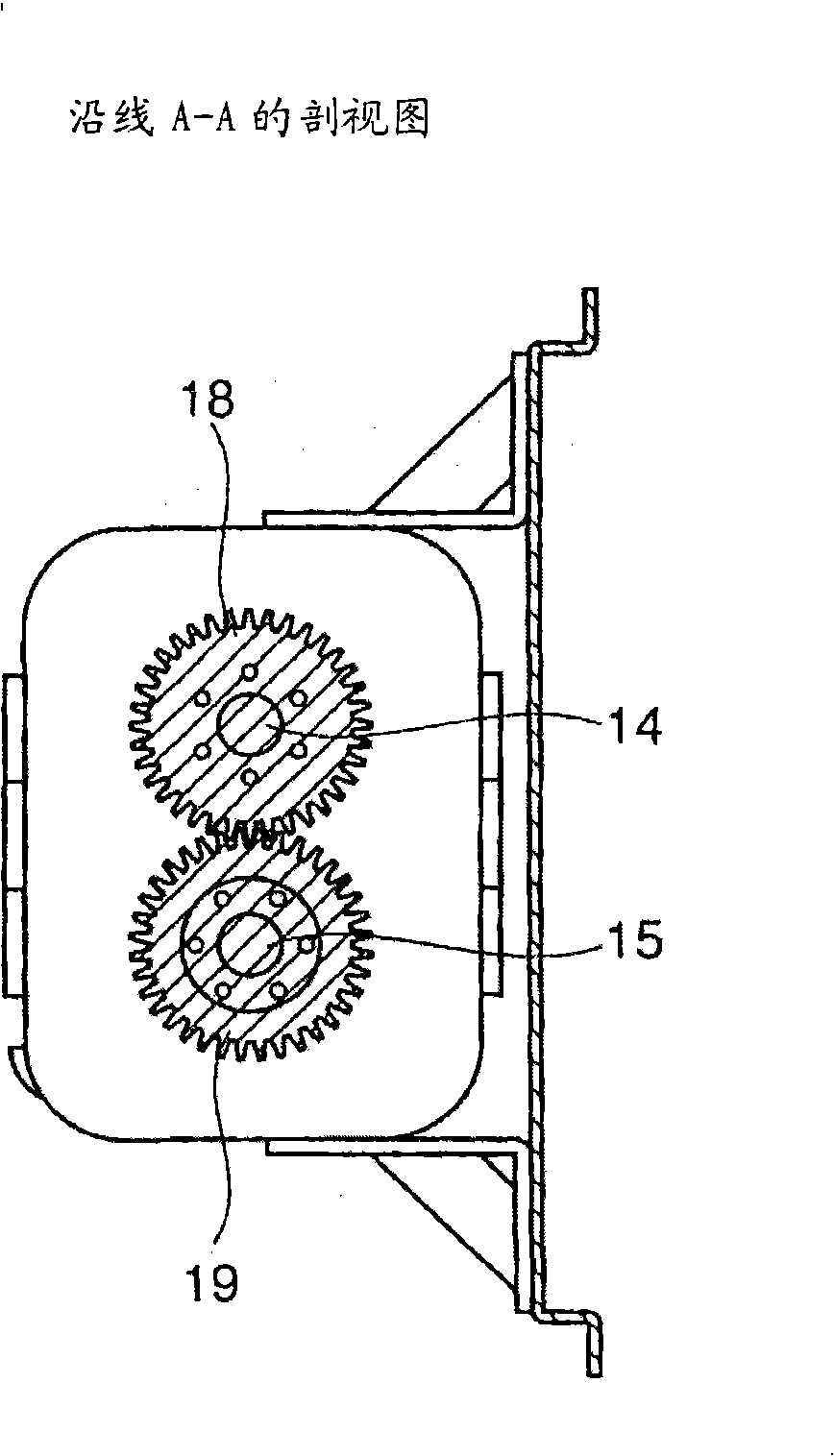

[0016] 1A is a plan view of an oil-free fluid machine constituted as a dry Roots mechanical vacuum pump with a drive transmission mechanism according to the present invention, FIG. 1B is its side view, and FIG. 1C is its front view. Figure 2A is a cross-sectional view along line A-A in FIG. 1A, and Figure 2B It is a transverse cross-sectional view along line C-C in FIG. 1A. Although the present invention will be described taking a dry mechanical vacuum Roots pump as an example, and it has two rotors equipped with a drive transmission mechanism, the drive transmission mechanism applied to the fluid machine of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com