Condenser condensed water sampling device separator for water and vapor

A technology of gas-water separator and sampling device, which is applied in the direction of sampling device, test sample preparation, steam generation, etc. It can solve the problems of poor adaptability, stability and reliability, achieve good reliability and reduce pressure head loss , the effect of stabilizing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

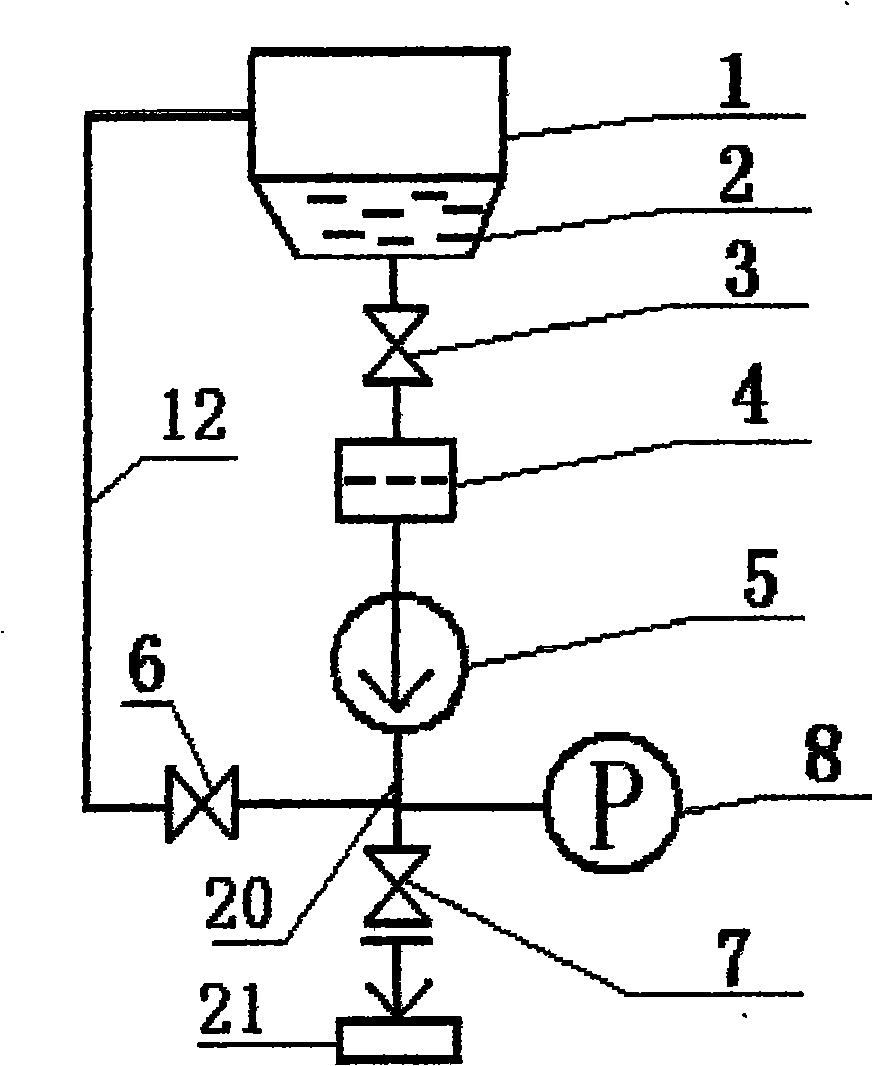

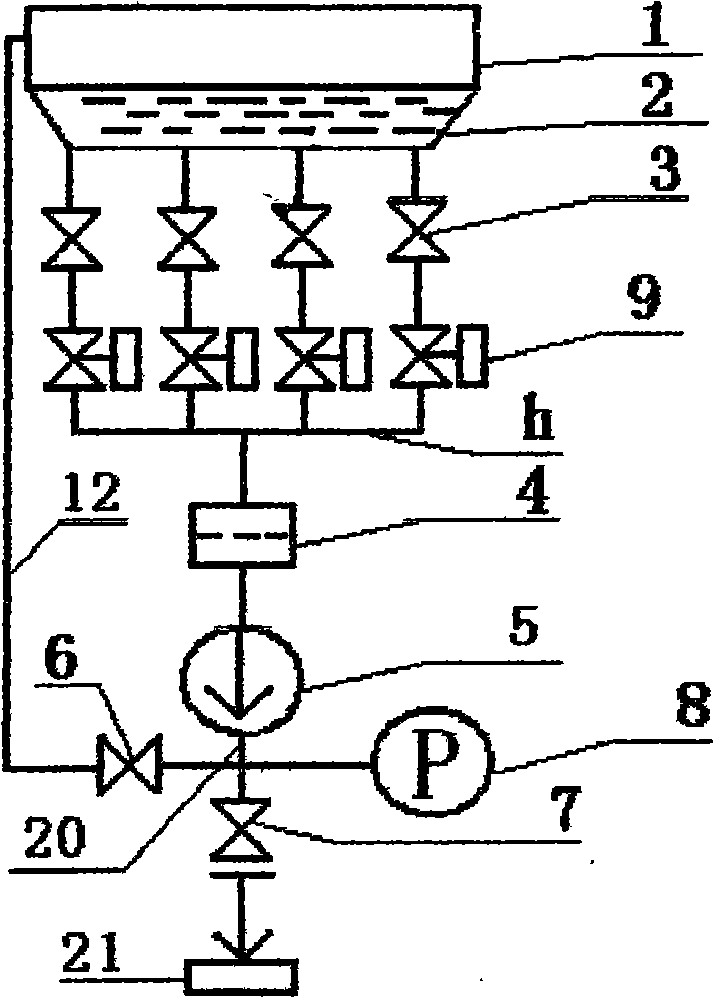

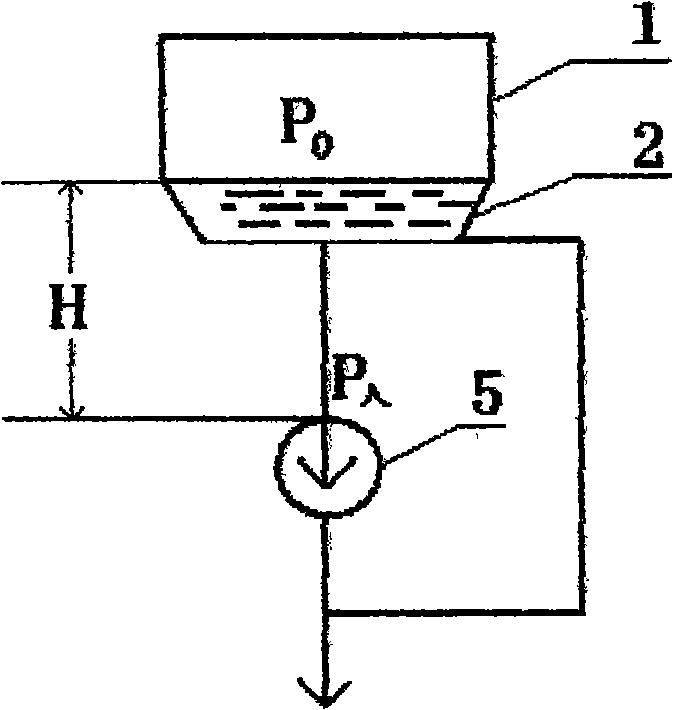

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: refer to Figure 4 The structure of the gas-water separator 10 of the condenser condensate sampling device of embodiment 1 is to have a tank body 13, a sample water distributor 14 is provided in the tank body 13, and an air outlet 15 is provided at the tank body 13 upper end, A sample water outlet 17 is provided at the lower end of the tank body 13 . Described sample water distributor 14 is a horizontal straight pipe 22, and the end of horizontal straight pipe 22 is closed, and the side wall of horizontal straight pipe 22 is provided with some outlet holes 16, and this kind of sample water distribution 14 from tank body 13 side walls Put it into the tank body 13 and be fixed on the side wall of the tank body 13 .

Embodiment 2

[0038] Embodiment 2: refer to Figure 5 , the structure of the gas-water separator 10 of the condenser condensate sampling device of embodiment 2 is basically the same as that of embodiment 1, the only difference is that the sample water distributor 14 is made of two straight pipes that are vertically fixed into one , the vertical straight pipe 23 is placed and fixedly connected on the upper end cover of the tank body 13, the two ends of the horizontal straight pipe 22 are open or closed, and the side walls of the horizontal pipe 22 are provided with some water outlet holes 16.

Embodiment 3

[0039] Embodiment 3: refer to Figure 6 The structure of the gas-water separator 10 of the condenser condensate sampling device of embodiment 3 is basically the same as that of embodiment 1, the only difference is that the sample water distributor 14 is an elbow 24 and a cone shower head 25 solid Connecting to form a whole, an elbow 25 is placed and fixedly connected on the side wall of the tank body 13, and a plurality of water outlet holes 16 are arranged at the lower end of the cone shower head 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com