Probe assembling

A probe and contact member technology, applied in the field of probe assembly, can solve the problems of difficulty in exposing the surface of the electrode block, damage to the circuit of the electrode block, damage to the surface of the electrode block, etc., to achieve the effect of reliable electrical connection and reduce the contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

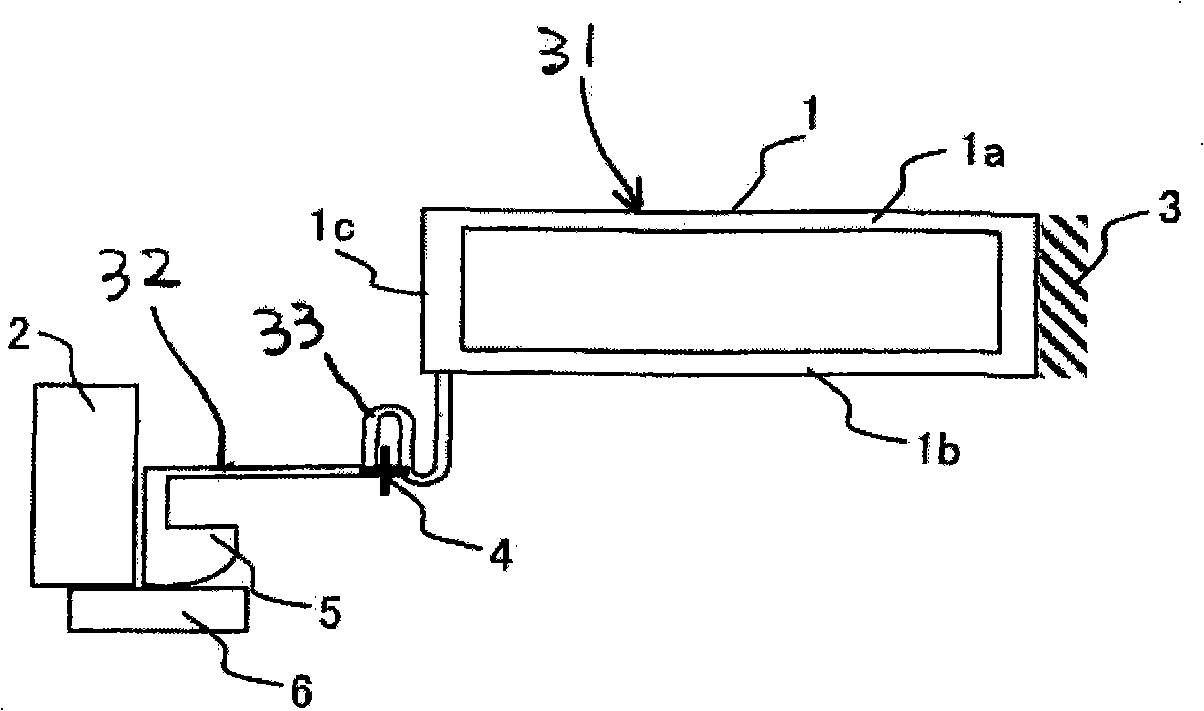

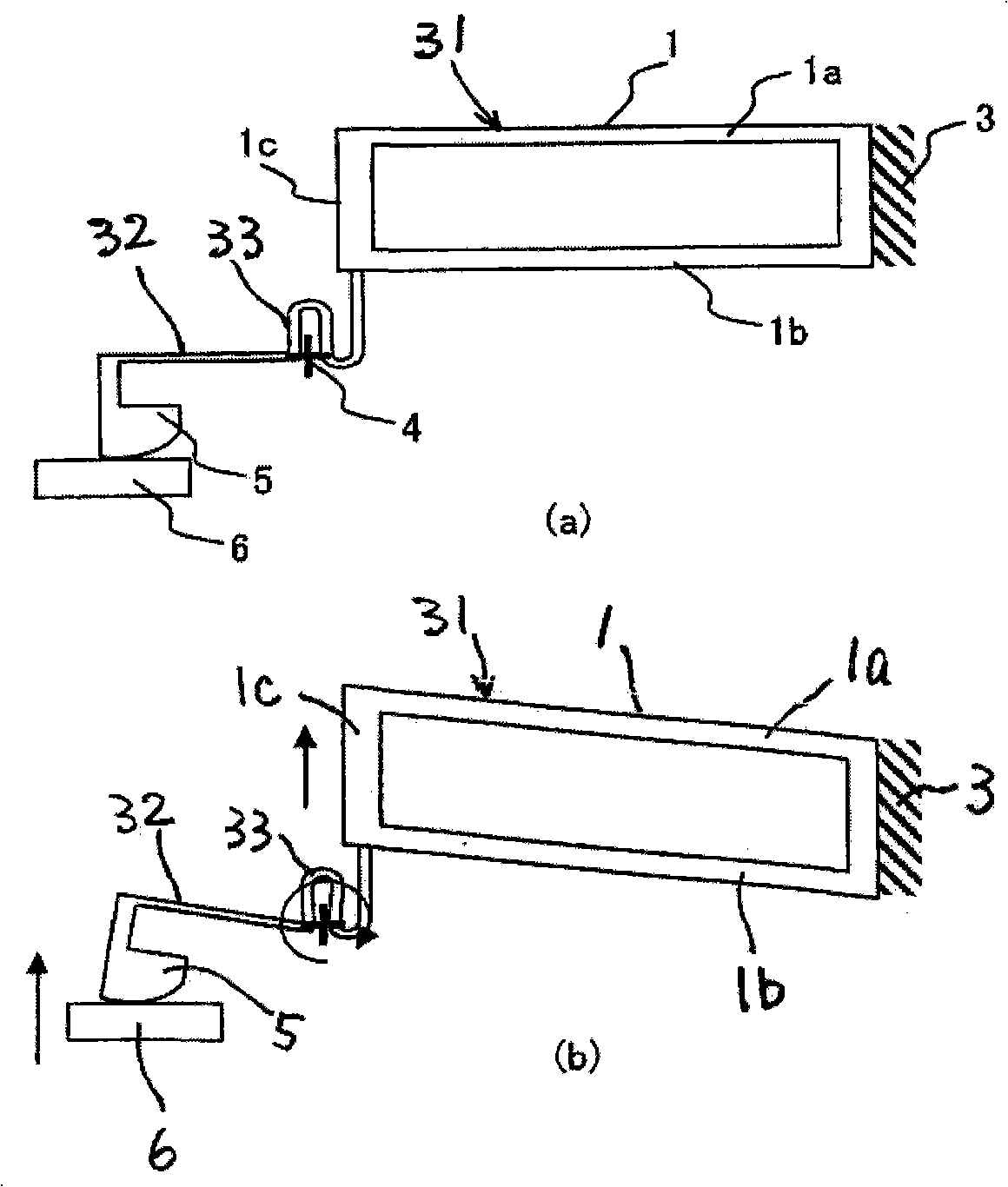

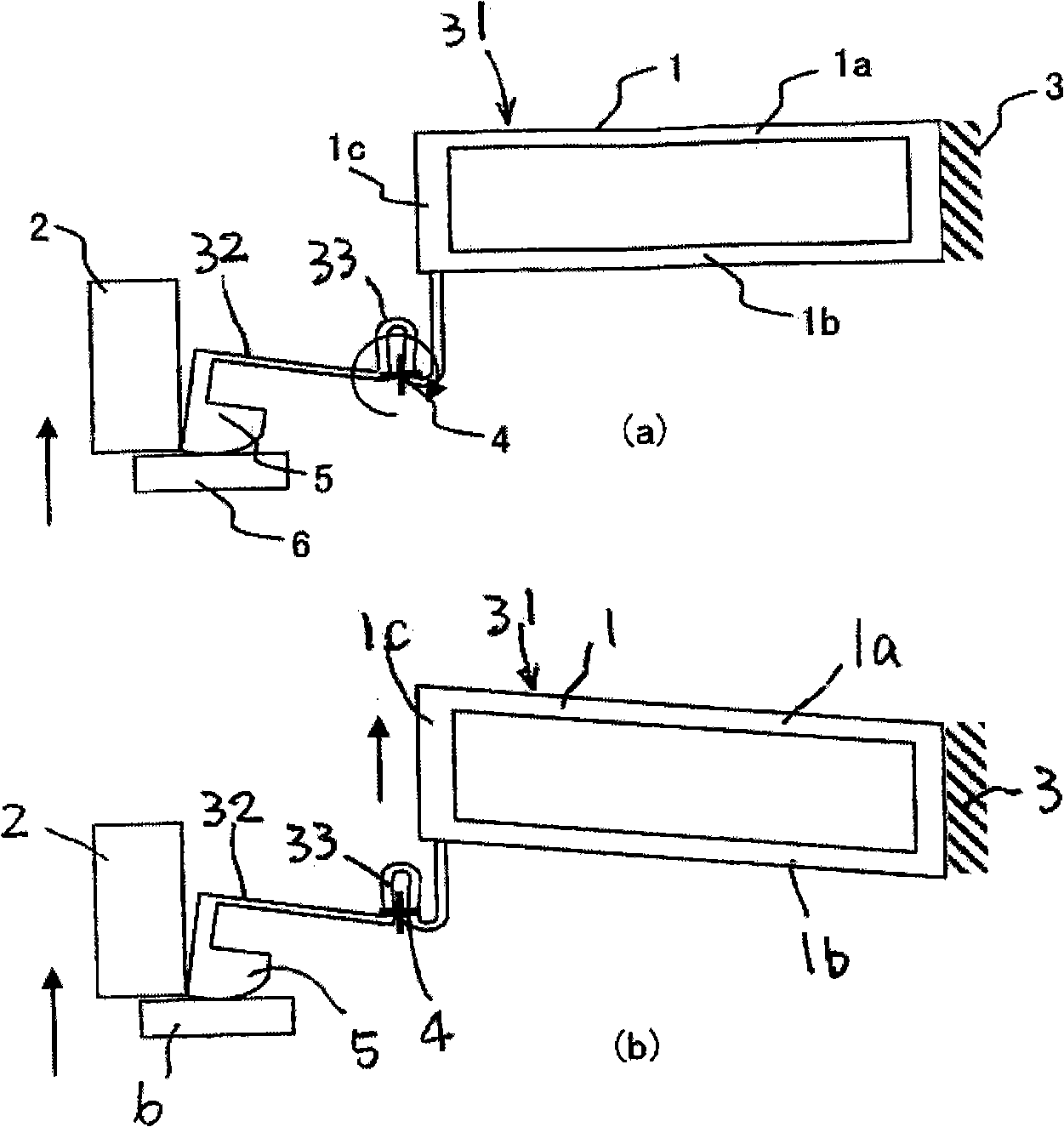

[0045] figure 1 It is a side view of the assembled probe of the first embodiment of the present invention; figure 2 and image 3 This is a side view illustrating the overall operation of this probe.

[0046] figure 1 The probe on the top is connected by parallel reeds 1, and its top and bottom sides form parallel beam parts 1a, 1b; on the other hand, the top part forms a vertical probe part 1c, and the base end constitutes a fixed The z deformation part 31 of the end 3; from the vertical probe part 1c of the parallel reed 1, extend the support arm 32, and set the top contact member 5 at the top end; the support arm 32 extends forward from the vertical probe part 1c , while setting the displacement absorbing part 33 in the central part; figure 1 In the illustration, the displacement absorbing part 33 is in reverse u-shape (u-shape is also possible), when the top contact member 5 is displaced (moved) in the up and down direction, in order to allow the top contact member ...

Embodiment 2

[0060] Image 6 and Figure 7 It is an illustration of the assembly of the probes related to the second embodiment of the present invention; Figure 8 It is an action description diagram of this implementation type; Image 6 It shows that the contact surface between the top contact members 5 is provided with a cleaning sheet (Cleaning Sheet) 7 made of a rough surface 7a; the structure of the cleaning sheet (Cleaning Sheet) 7 is for example Figure 7 As shown, a gap through which the probe can pass is provided on the resin sheet, and a cleaning sheet (Cleaning Sheet) 71 is provided on the single beam at the side of the gap, and the contact surface of the top contact member 5 can be coated with Microparticles such as cloth diamonds are realized; in addition, with the top of the rough surface 7a, the top contact member 5 of the contact part, after the cleaning sheet (Cleaning Sheet) 7 is set, through the relative offset, the rotation of the top contact member is accompanied by ...

Embodiment 3

[0065] Figure 9 It is an explanatory diagram of the tip contact member of the probe related to the third embodiment of the present invention; the shape of the tip contact member shown in Embodiments 1 and 2 can also be used such as Figure 8 The zigzag shape shown in the figure is used to promote the destruction of the oxide film, and through the rigid design and combination of the top contact components, a more suitable friction amount can be set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com