Electrical machine having permanent magnets

A permanent magnet and rotor technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problem of increasing the axial length of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

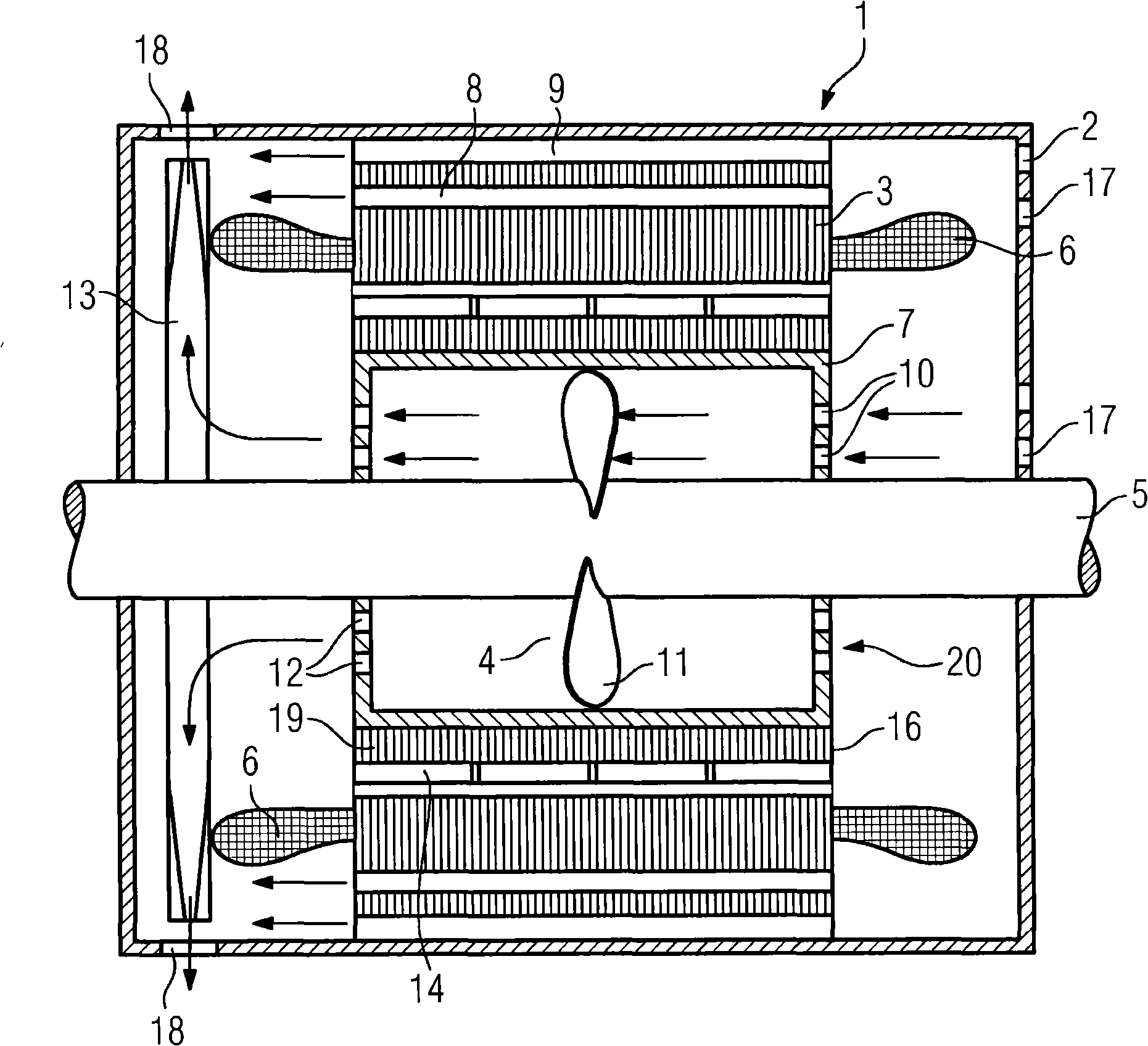

[0021] The drawing shows a schematic diagram of an electric machine 1 , in particular a permanent magnet synchronous machine arranged in a housing 2 . The electric machine comprises a stator 3 in which a winding system is arranged in a plurality of slots, this winding system forming an end winding 6 at the end face of the stator 3 . The winding system is in particular a three-phase winding system, in which both conventional winding techniques (ie short-pitch windings) and toothed coils can be used.

[0022] Tooth-wound coils are coils which each only wrap around one mechanical tooth of the stator 3 . The stator 3 is embodied as a lamination stack and comprises a plurality of cooling channels 8 extending substantially in the axial direction. A cooling channel 9 is also provided between the housing 2 and the stator 3, but in other embodiments, the cooling channel 9 is not a necessary component; in addition, even without the cooling channel 9, the working principle of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com