Ceramic tile micro mist cloth technique method and equipment

A process method and technology of porcelain tiles, which is applied in the field of porcelain tile production, can solve the problems of lack of three-dimensional particles and flatness of the decorative surface, and achieve the effect of rich texture and strong texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

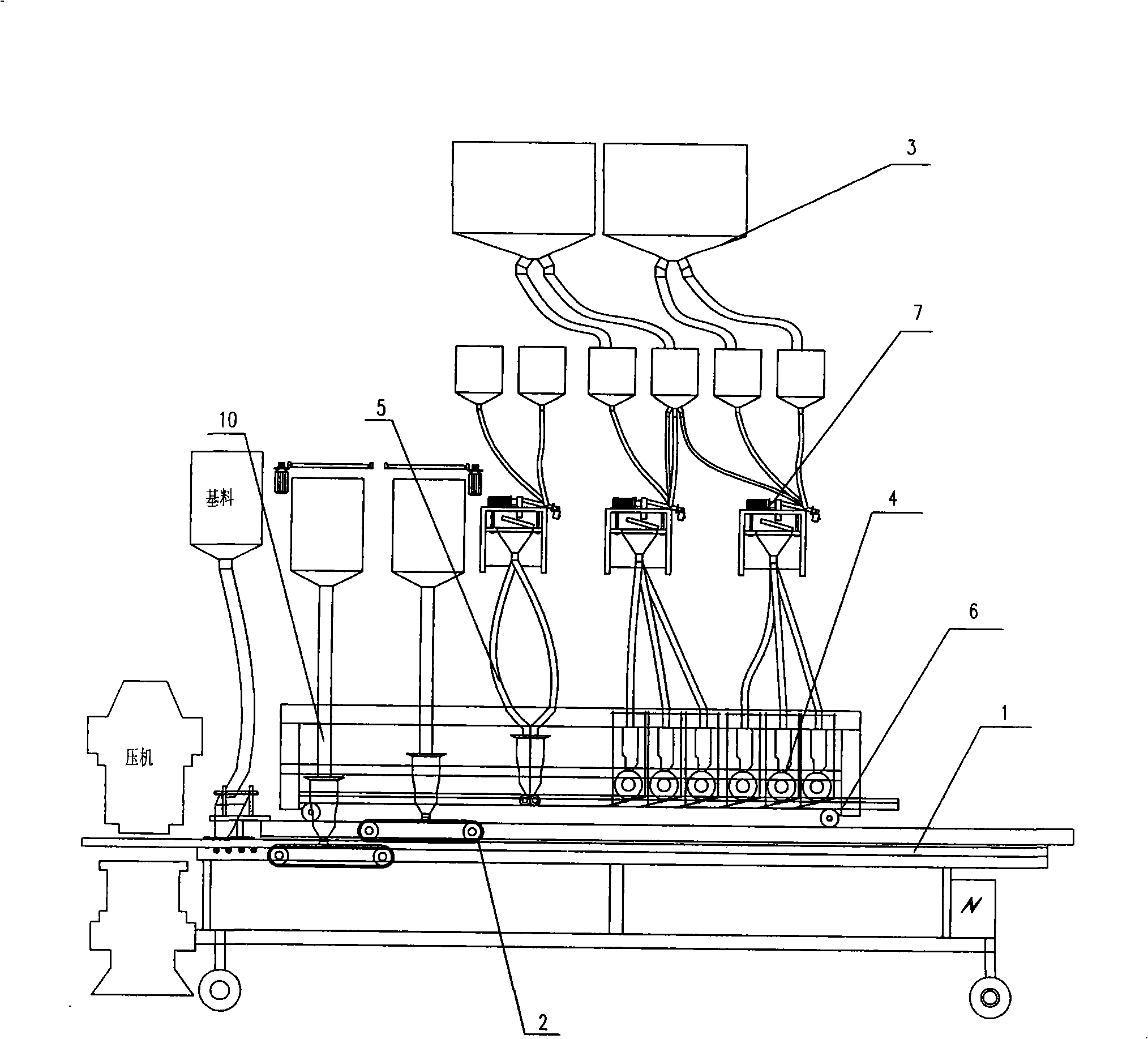

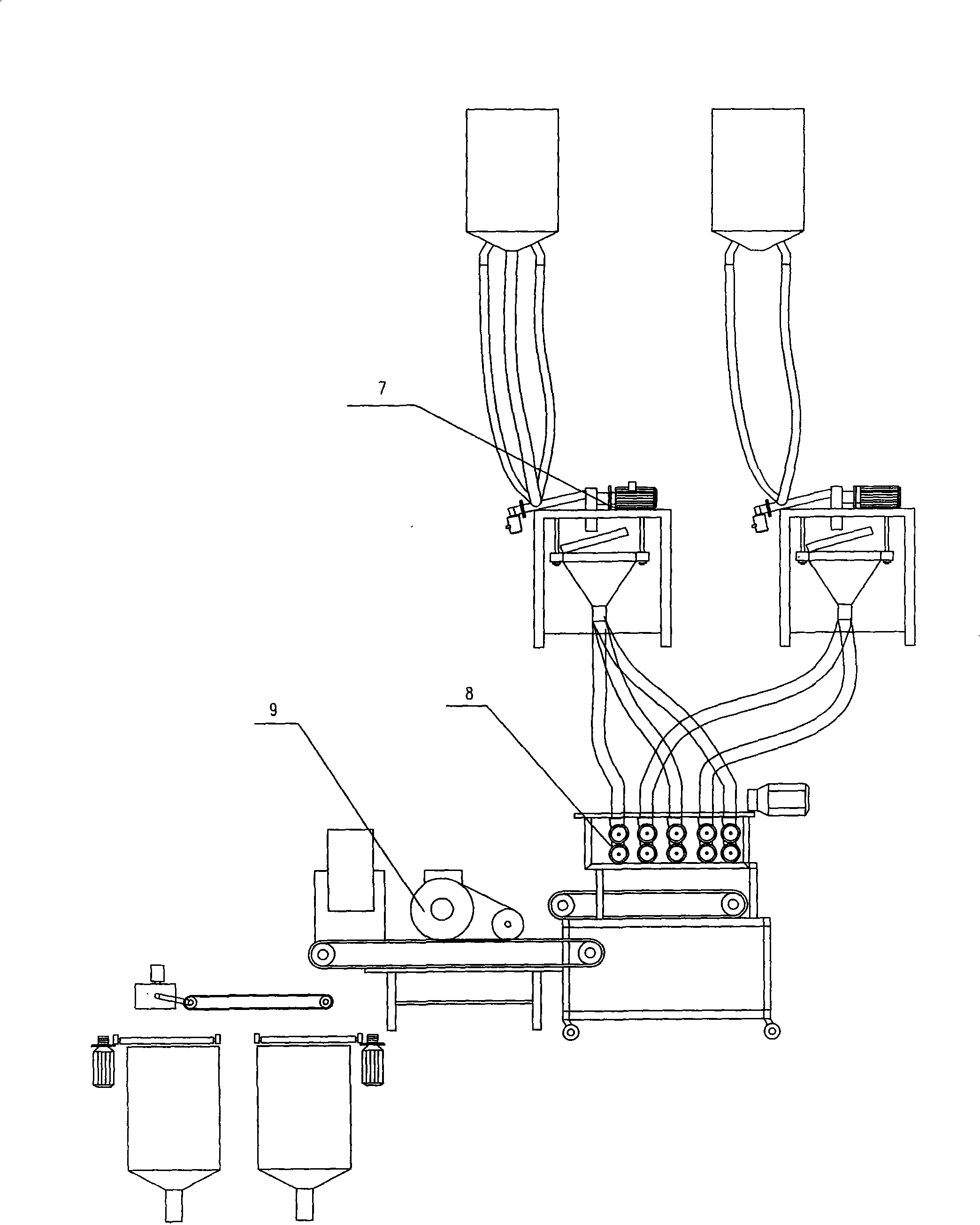

[0018] The fine powder distributing process for porcelain tiles of the present invention is improved on the basis of the existing anti-beating micro powder distributing process and line distributing process, and specifically includes: firstly, the flake granular material distributing device is directly placed in the grid. The sheet-like granular material with hierarchical structure is formed by pre-pressing, and forms irregular accumulation with the remaining material in the grid; then a thin layer of powder is applied on the surface of the irregular accumulation to form a random line decorative texture; finally, the micro-powder pattern The fabric is directly fed by the belt to fill the grid without going through the material box, and completes the cloth work of the three-dimensional decorative pattern in the grid.

[0019] The specific operation process is as follows:

[0020] First of all, the push rack returns to its original position after the last cycle of action, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com