Device for burning Jun porcelain by hot coal gas

A technology of hot gas and Jun porcelain, which is applied in the field of equipment for firing Jun porcelain with hot gas, which can solve the problems of long firing time, difficult effective control, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

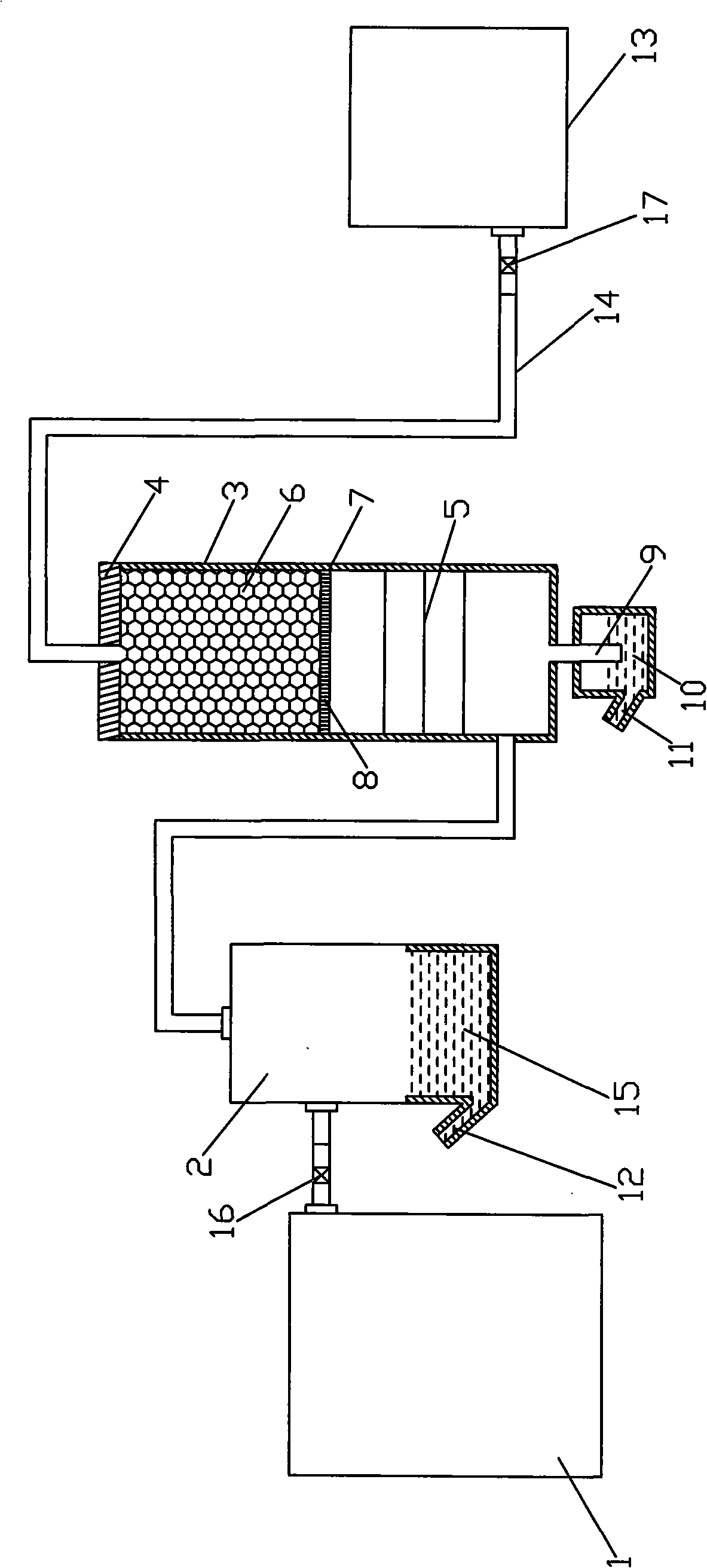

[0005] The specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0006] Provided by the accompanying drawings, the present invention includes a gas generator, a cyclone dust collector, an adsorption dust collector, and a Jun porcelain kiln. The outlet of the gas generator 1 hot gas passes through the gas pipe through the cyclone dust collector 2 and the adsorption dust collector 3 The lower part of the hot gas inlet is connected, and the adsorption dust collector 3 housing is horizontally equipped with a movable filter plate layer (adsorption sheet) 5, and the upper part of the movable filter plate layer has a particle adsorption filter screen 6 in the housing, and the particle adsorption filter screen has a hole 8 in the lower part. Partition plate 7, the housing bottom of movable filter plate layer 5 bottoms has the air duct 9 that stretches into lower water-sealed pool 10, and the gas outlet pipe 14 that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com