Thermocouple unit for casting ingot heating stove measuring aluminum ingot temperature

A thermocouple and heating furnace technology, which is applied to measuring devices, electrical devices, thermometers, etc., can solve the problems of unreal temperature measurement, low accuracy, unsafe manual operation, etc., and achieves increased authenticity, flexible use, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

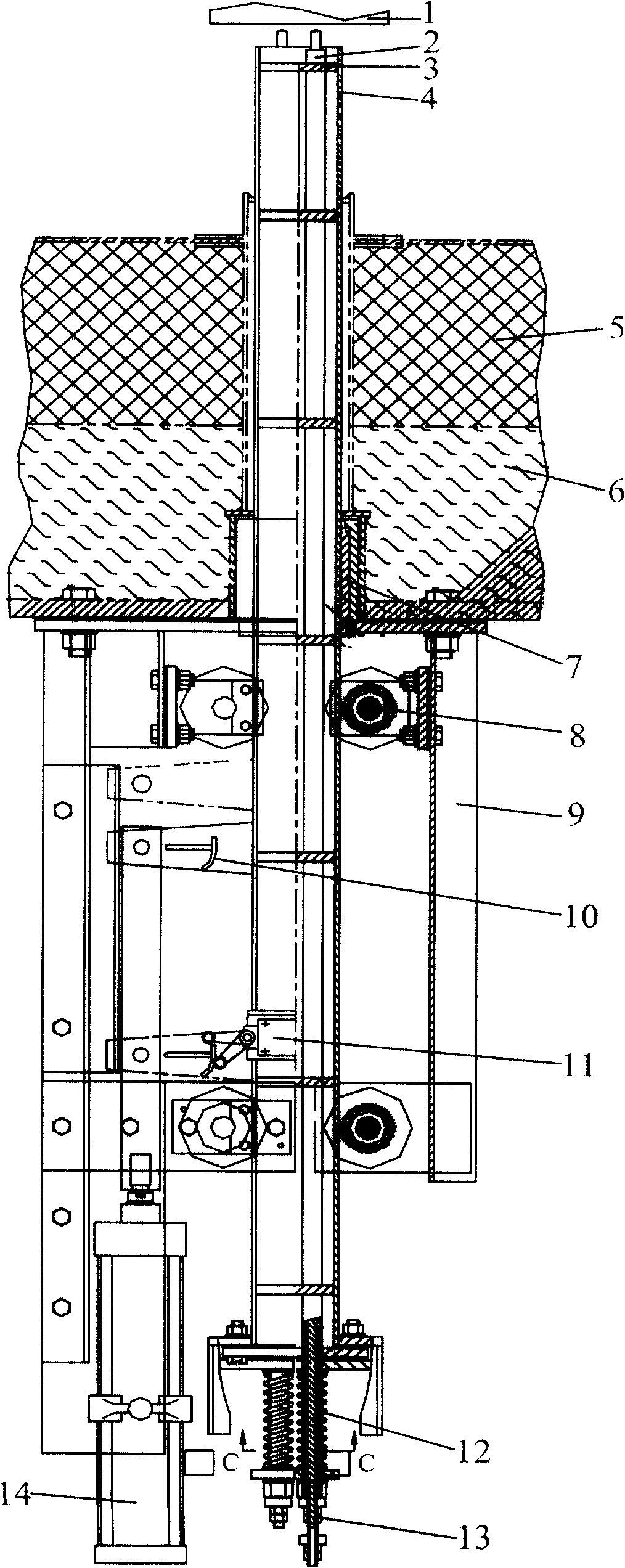

[0026] On the aluminum slab heating furnace, it is necessary to monitor the surface temperature of the aluminum slab during the heating process in real time and participate in process control. In addition, in order to meet the hot rolling control requirements of large-scale production, the real temperature data of the metal needs to be recorded before being heated out of the furnace. Send to the main control room of hot rolling. The invention provides a complete and reasonable thermocouple device for detecting the temperature of the ingot in real time, which can be directly installed on the furnace bottom of the heating furnace to complete the detection of the temperature of the ingot in the furnace.

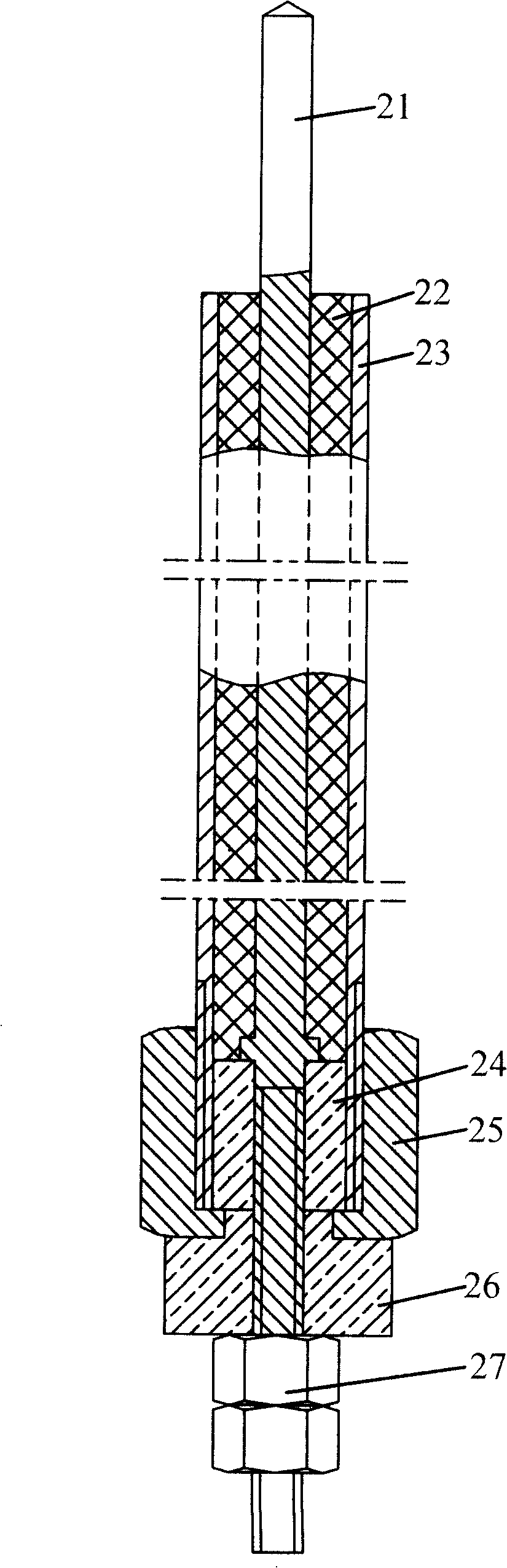

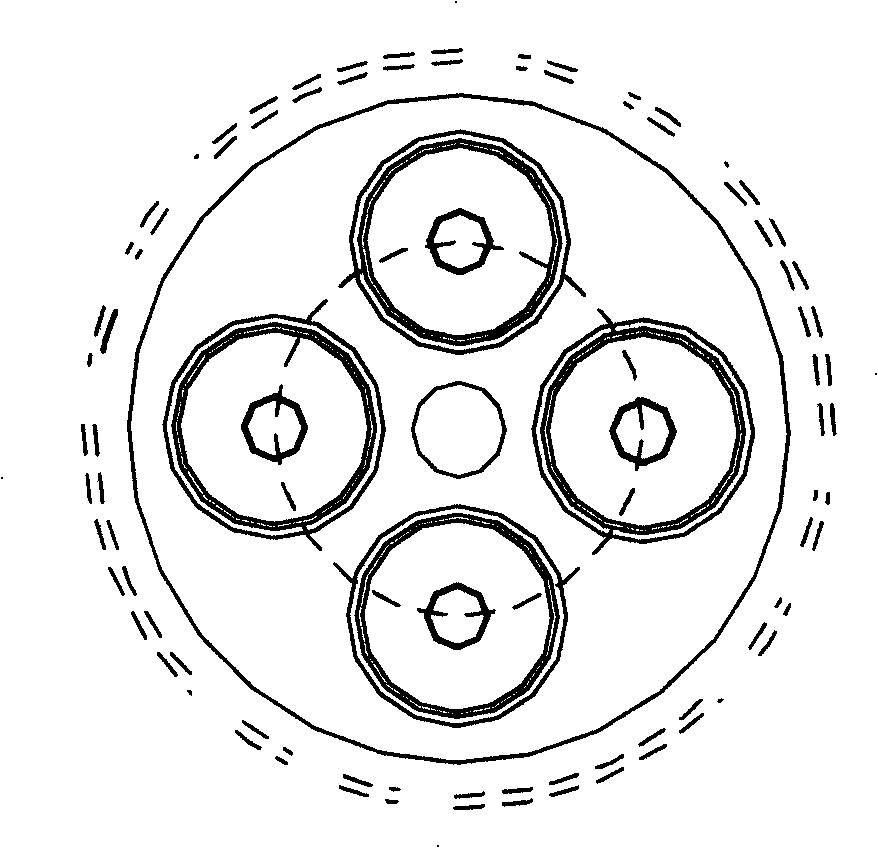

[0027] Such as Figure 1 ~ Figure 4 As shown, the thermocouple device for measuring the temperature of the aluminum ingot in the ingot heating furnace includes thermocouple wires, the front ends of the thermocouple wires form a joint section, and the output wires are drawn from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com