A multi-layer anti-static shielding slice material and its processing method

A multi-layer structure, anti-static technology, applied in the direction of magnetic/electric field shielding, static electricity, electrical components, etc., can solve problems such as no solution, achieve good anti-static and shielding functions, reliable anti-static and shielding functions, high The effect of using intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now the present invention is further described in detail in conjunction with the accompanying drawings:

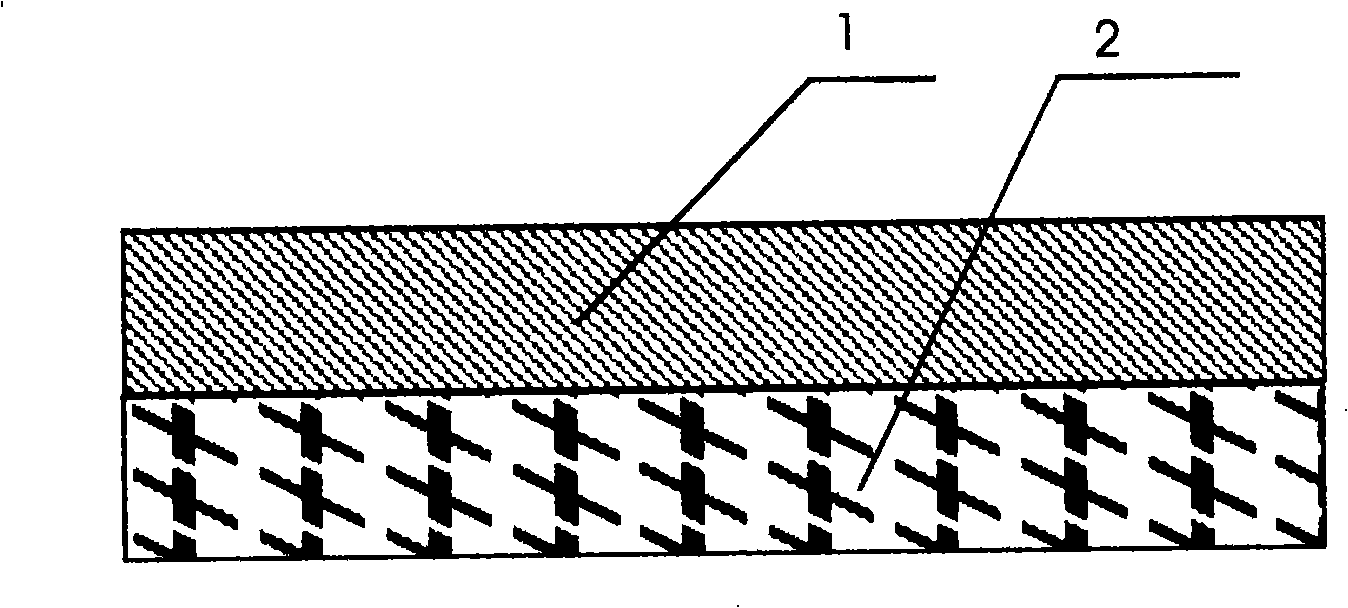

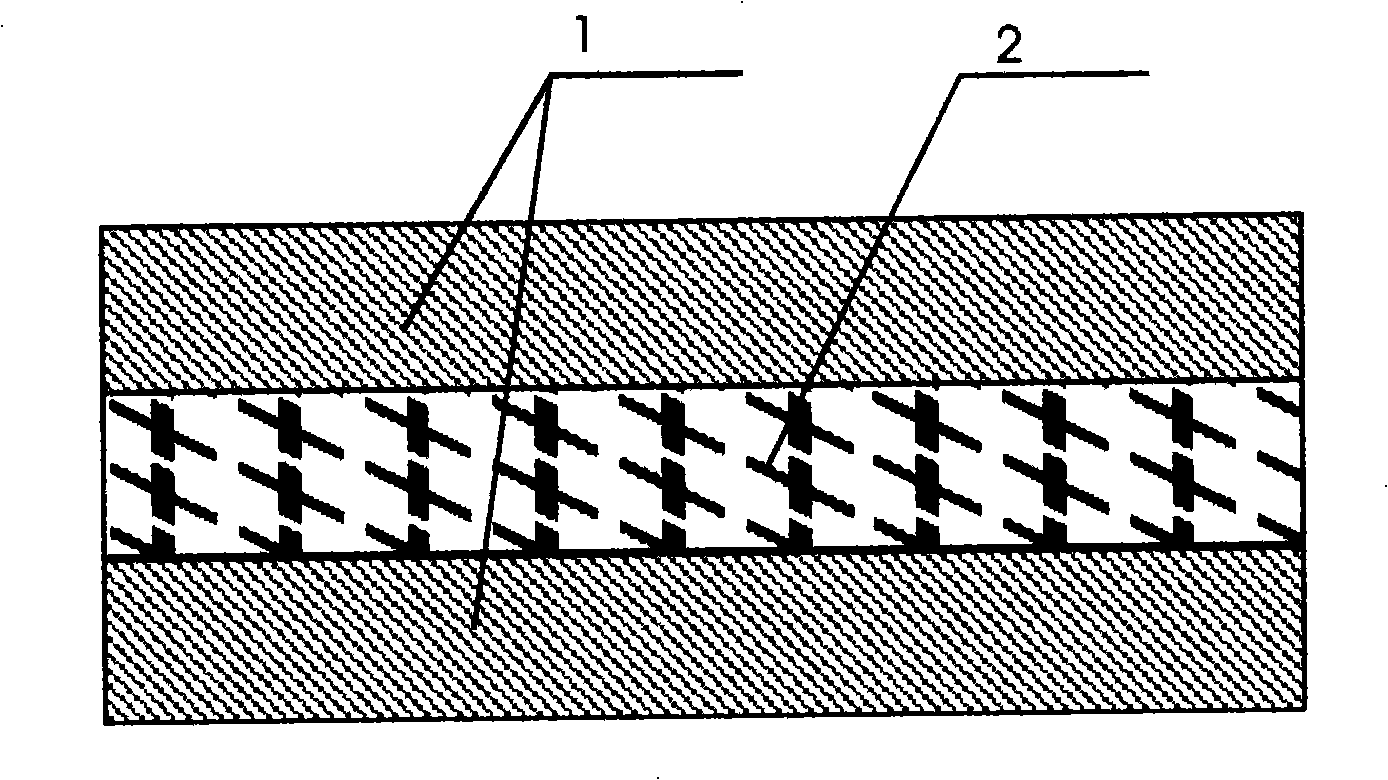

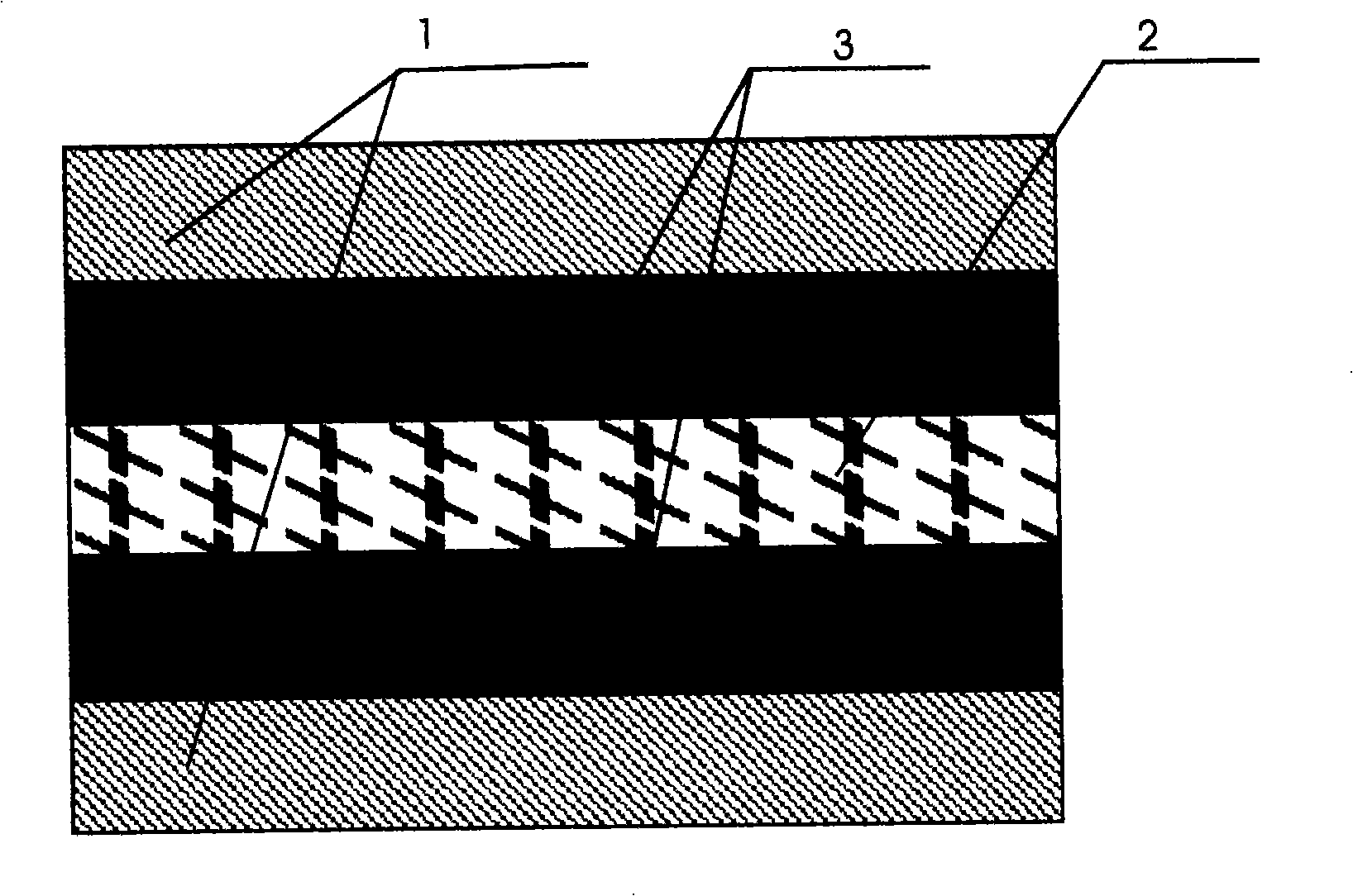

[0020] The technical solution adopted by the present invention includes the following content: an antistatic shielding sheet with a multilayer structure, the sheet body is composed of at least two layers of materials, and includes at least one antistatic layer and at least one layer shielding. The multi-layer structure in this sheet is completed by one-time molding through a multi-layer composite sheet production extruder. In actual use, it is better to arrange the antistatic layer and the shielding layer at a distance from each other. However, during use, it is not ruled out that two or more antistatic layers and two or more shielding layers are spaced apart from each other at the same time. Such as figure 1 Shown is the most basic composition of the sheet in the present invention, the antistatic layer 1 and the shielding layer 2 are simply combined to form a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com