Transverse dipping method for preliminary dip material

A prepreg, horizontal technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of insufficient infiltration of prepregs, increase equipment investment costs, improve lamination quality, and increase residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

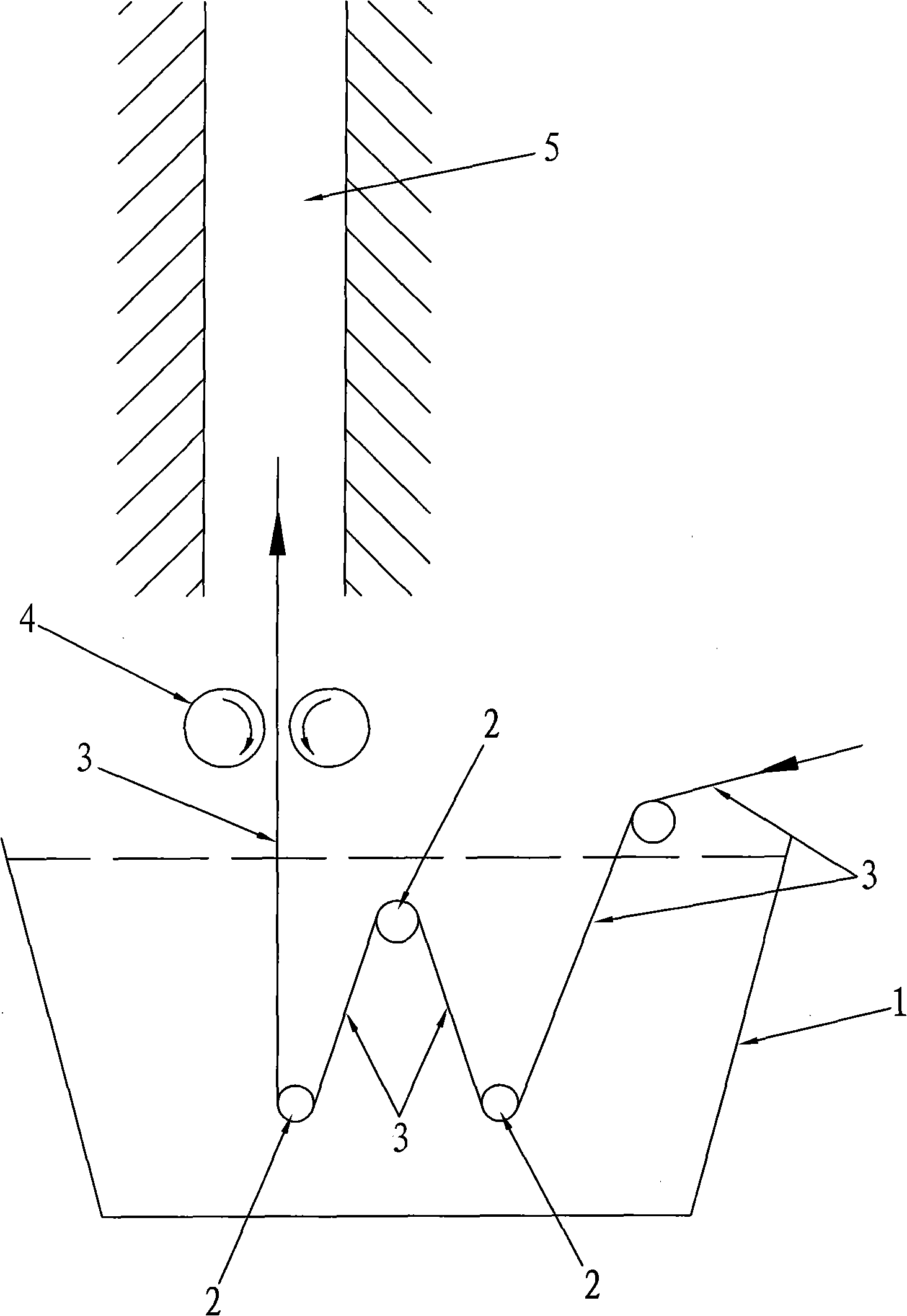

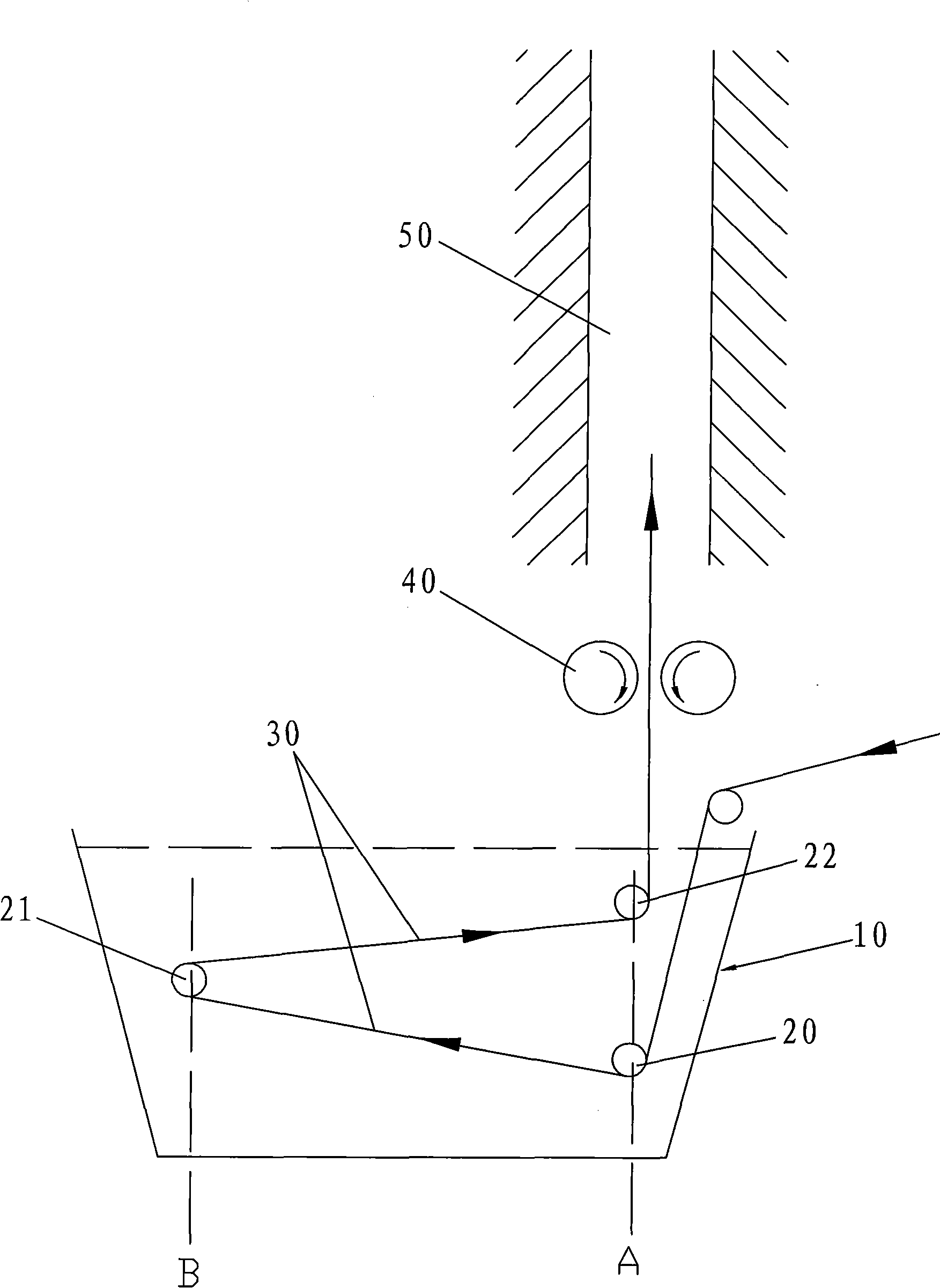

[0020] like figure 2 As shown, this embodiment describes the transverse infiltration method with the help of the applied prepreg infiltration device. The above prepreg can be selected from glass fiber cloth, fiber paper or fiber fabric; wherein, in this embodiment, the sizing tank There are 3 guide rollers in total, namely the first guide roller 20, the second guide roller 21 and the third guide roller 22; the prepreg 30 is sent longitudinally to the bottom of the glue tank 10 filled with resin glue, and then wound around On the first guide roller 20, the second guide roller 21, and the third guide roller 22, and the first guide roller 20 and the third guide roller 21 are located on a longitudinal row A, and the second guide roller 21 is located on another longitudinal row B Above, the longitudinal row A and the longitudinal row B are vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com