Integration power winch for oil-well rig

A winch and drilling rig technology, applied in the field of integrated power winches for oil drilling rigs, can solve problems such as low efficiency, difficult installation, and large structure of the winch and power system, and achieve the effects of reducing workload, convenient operation, and enhancing mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

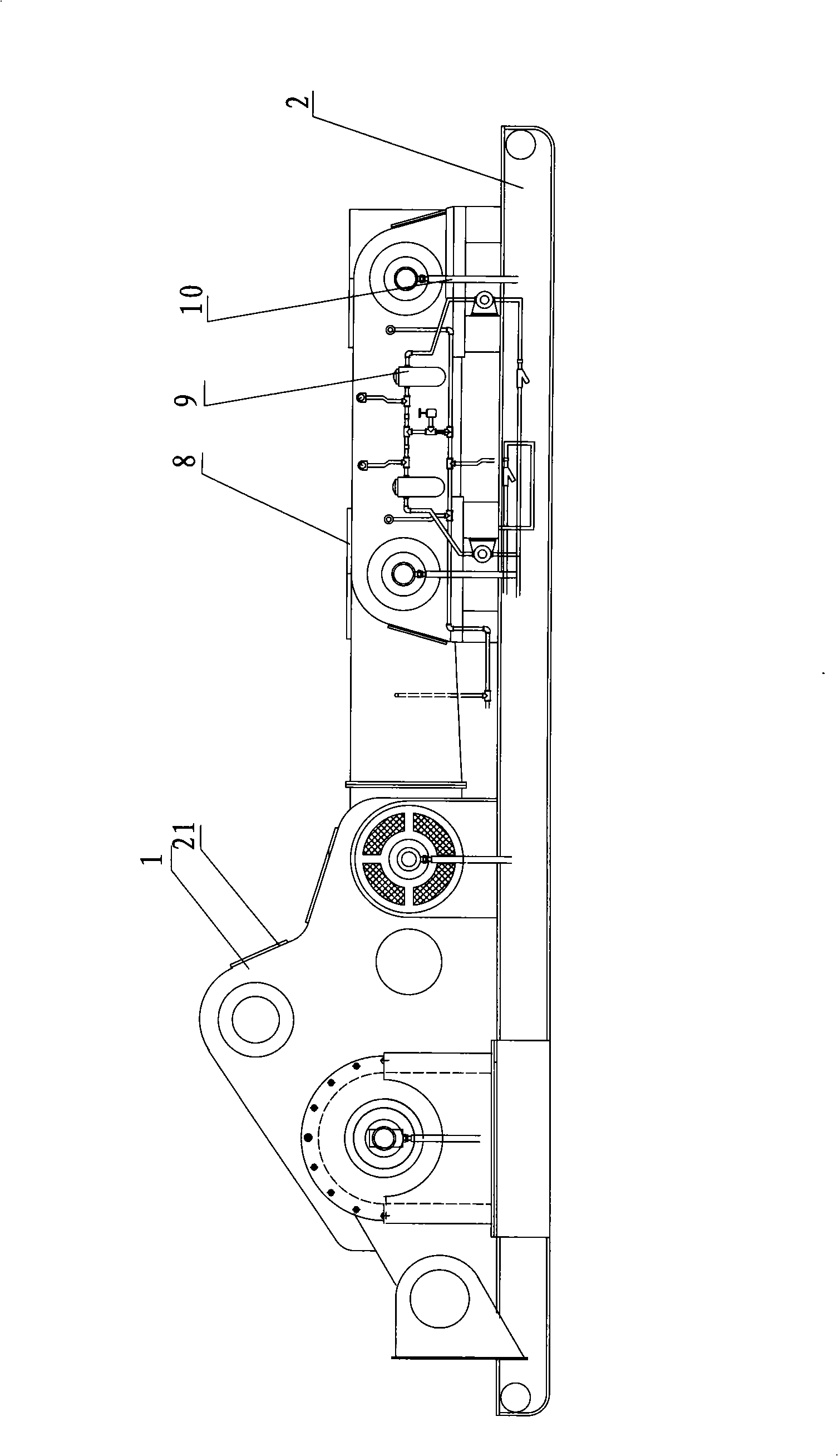

[0015] As shown in Figures 1 and 2, an integrated power winch for an oil drilling rig includes a winch frame 1, a winch bottom skid 2, a chain box 3, a drum shaft 4, an input shaft 5, a cat head shaft 6, and a turntable bridge shaft 7 , power unit 8, hydraulic system 9 and air control system 10, the winch frame 1 and winch bottom skid 2 are fixed as a whole, and the chain box 3, power unit 8, hydraulic system 9 and air control system 10 are installed on the winch On the bottom skid 2, the drum shaft 4, the input shaft 5, the cat head shaft 6, and the turntable bridge bridge shaft 7 are installed on the winch bottom skid 2 through the bearing seat 11.

[0016] The high and low speed clutches on the described drum shaft 4 and the inertia brake clutches on the turntable bridge shaft all adopt the push plate clutch 12. One side of the drum shaft 4 is equipped with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com