Self-ignition fatalness decision method of coal

A judging method and dangerous technology, which is applied in the field of judging the difficulty of spontaneous combustion, can solve the problems of small heat production, practical significance, long natural heating process, etc., and achieve the effect of improving effectiveness, high reliability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

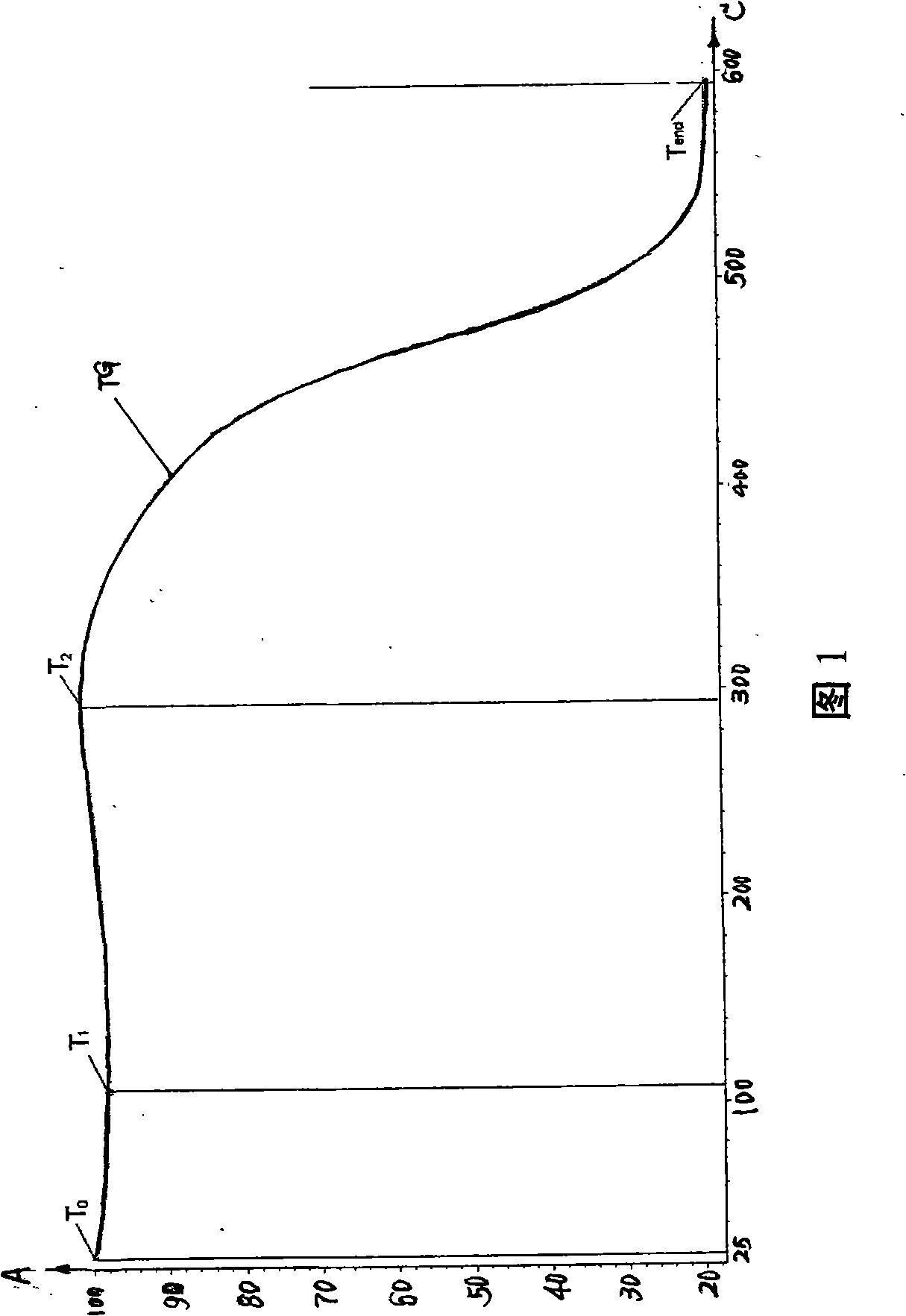

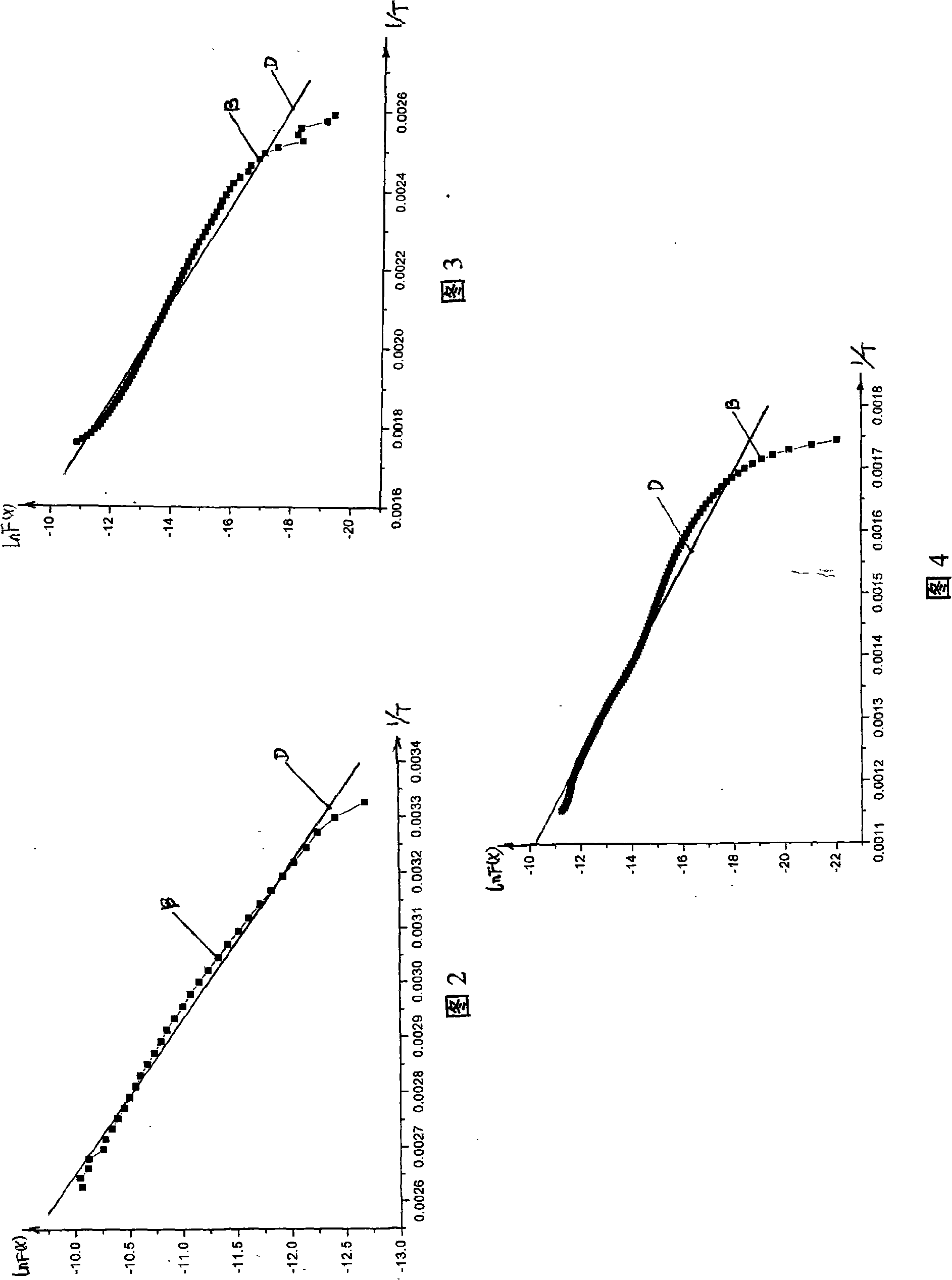

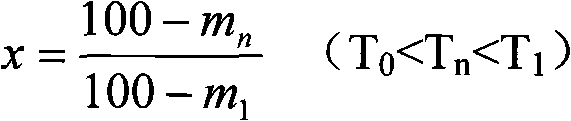

[0028] Referring to the accompanying drawings, a method for judging the spontaneous combustion risk of coal: first, sampling: seal the coal samples collected at the coal mining face and bring them back to the laboratory, grind the coal samples to below 50 mesh in the laboratory, and put them into Affix a label to the dry and clean jar, the label indicates the location of sampling and the time of coal sample preparation, and seal the jar with a rubber sleeve; the second is the test: use a thermogravimetric analyzer to conduct the experiment; the temperature in the experiment The control and data acquisition are all completed by thermogravimetric analyzer; the experimental conditions are determined as follows: coal sample mass 13.658mg, reaction gas is O 2 , the flow rate is 10ml / min, the carrier gas is N 2 , the flow rate is 40ml / min, the heating rate is 5℃·min -1 , to simulate the oxidative spontaneous combustion of coal samples in air, from room temperature at 25°C to consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com