Wireless intelligent cuisine apparatus, cuisine stove and accessories, cuisine device and working method

A cooking utensil and intelligent cooking technology, which is applied to cooking utensils, electric heating devices, instruments, etc., can solve the problems of not being able to fry or fry, not being able to ensure strict sealing and waterproofing, and not being able to reduce the labor burden, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

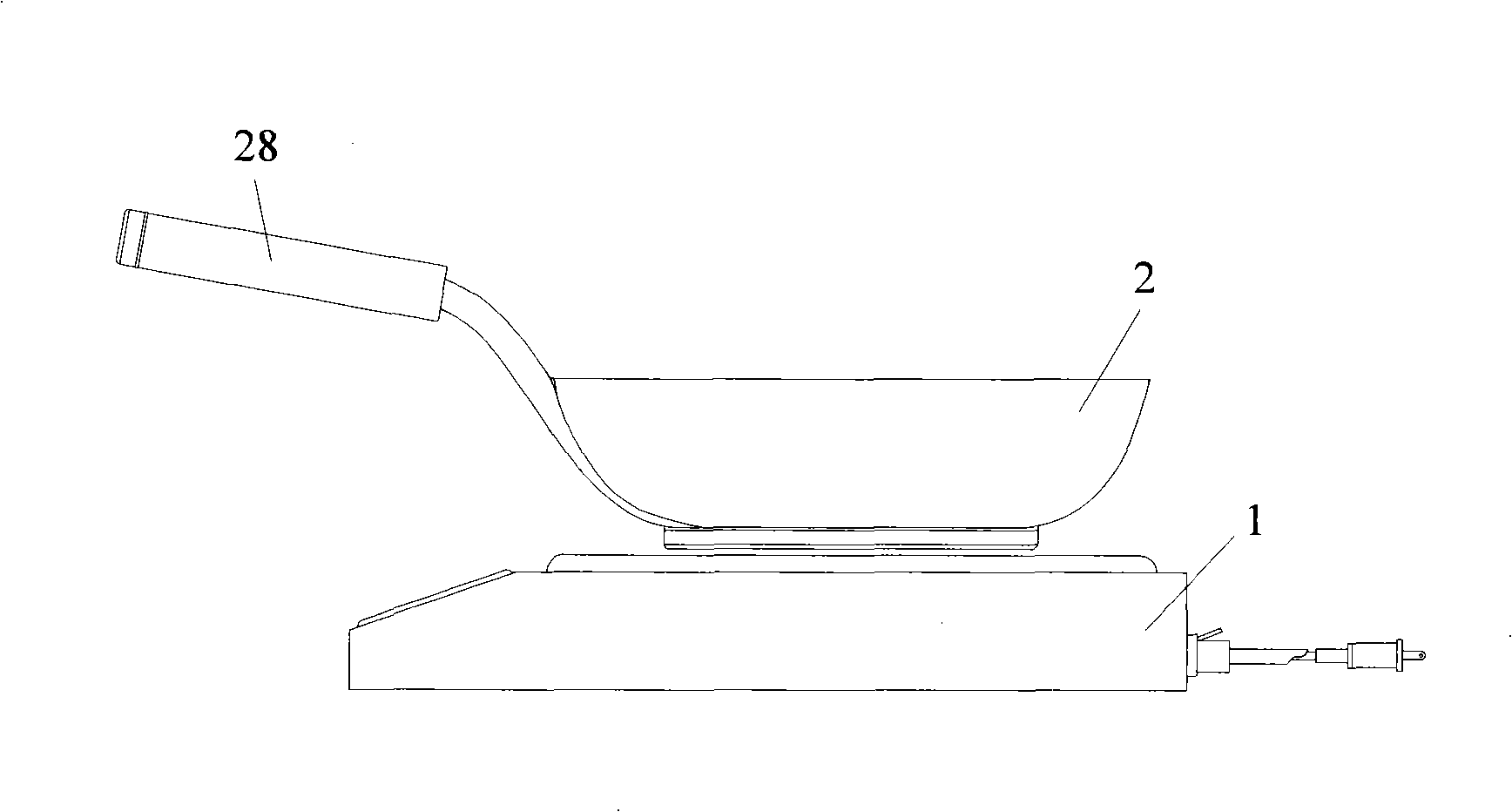

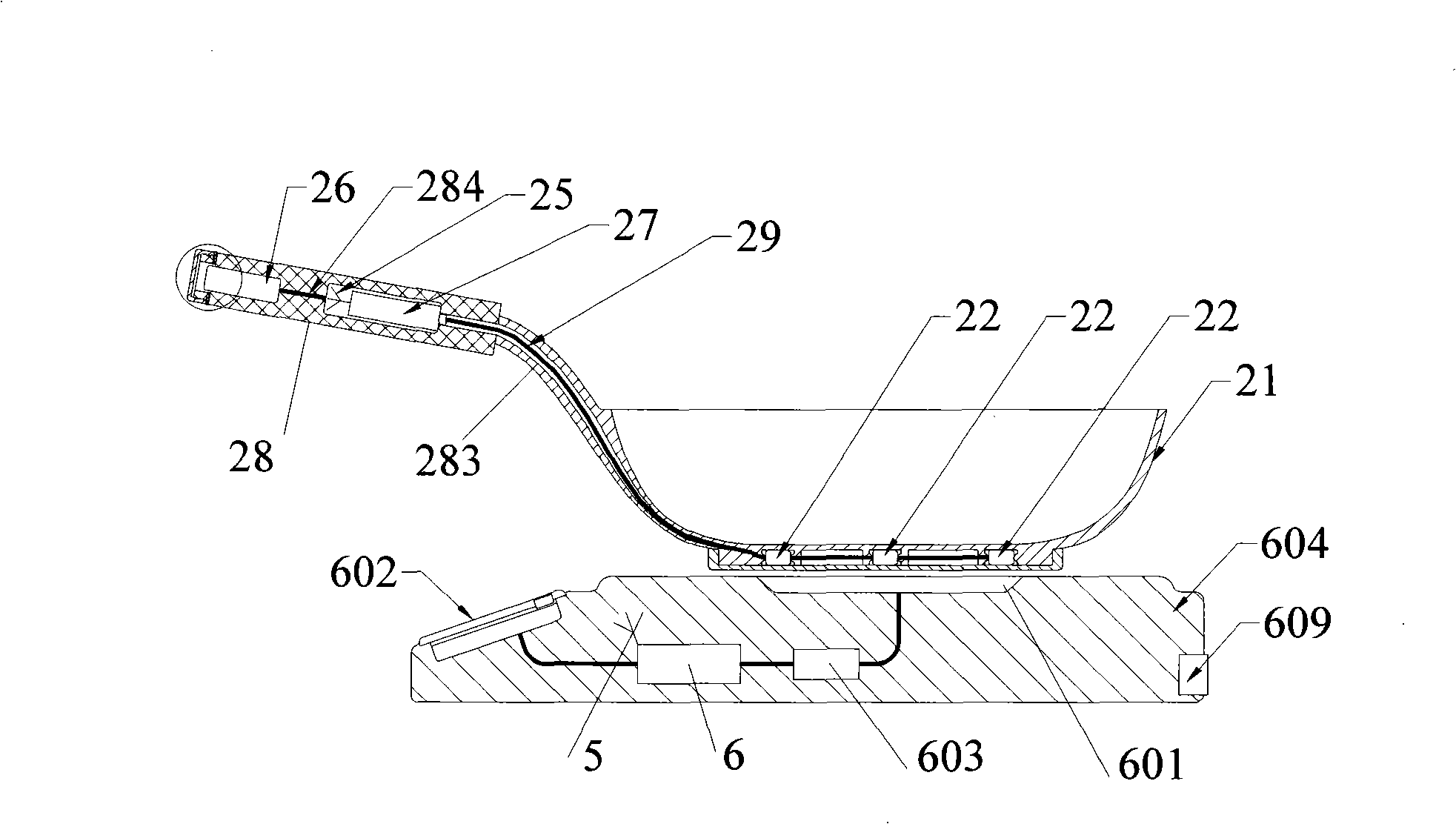

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 As shown, the wireless intelligent cooking device of this embodiment includes a stove 1 and a cooking utensil 2, wherein the stove 1 is provided with an intelligent controller 6, a wireless communication module 4 and an antenna 5, and the cooking utensil 2 is equipped with With a temperature sensor 22, an electronic circuit 23, a wireless communication module 24, an antenna 25 and a battery 26, the electronic circuit 23 includes a converter 231 and a control chip 232, and the cooking appliance 2 is compatible with the stove 1 . The control chip 232 is a microprocessor, or a programmable device that can be written into a program; the stove is an electric heating stove.

[0042] The stove 1 further includes a stove shell 604 , a heating element 601 , and a heating element controller 603 , and the heating element 601 is connected to the heating element controller 603 . The heating element 60...

Embodiment 2

[0053] Such as image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the stove is a gas stove, and the heating element is a gas hob.

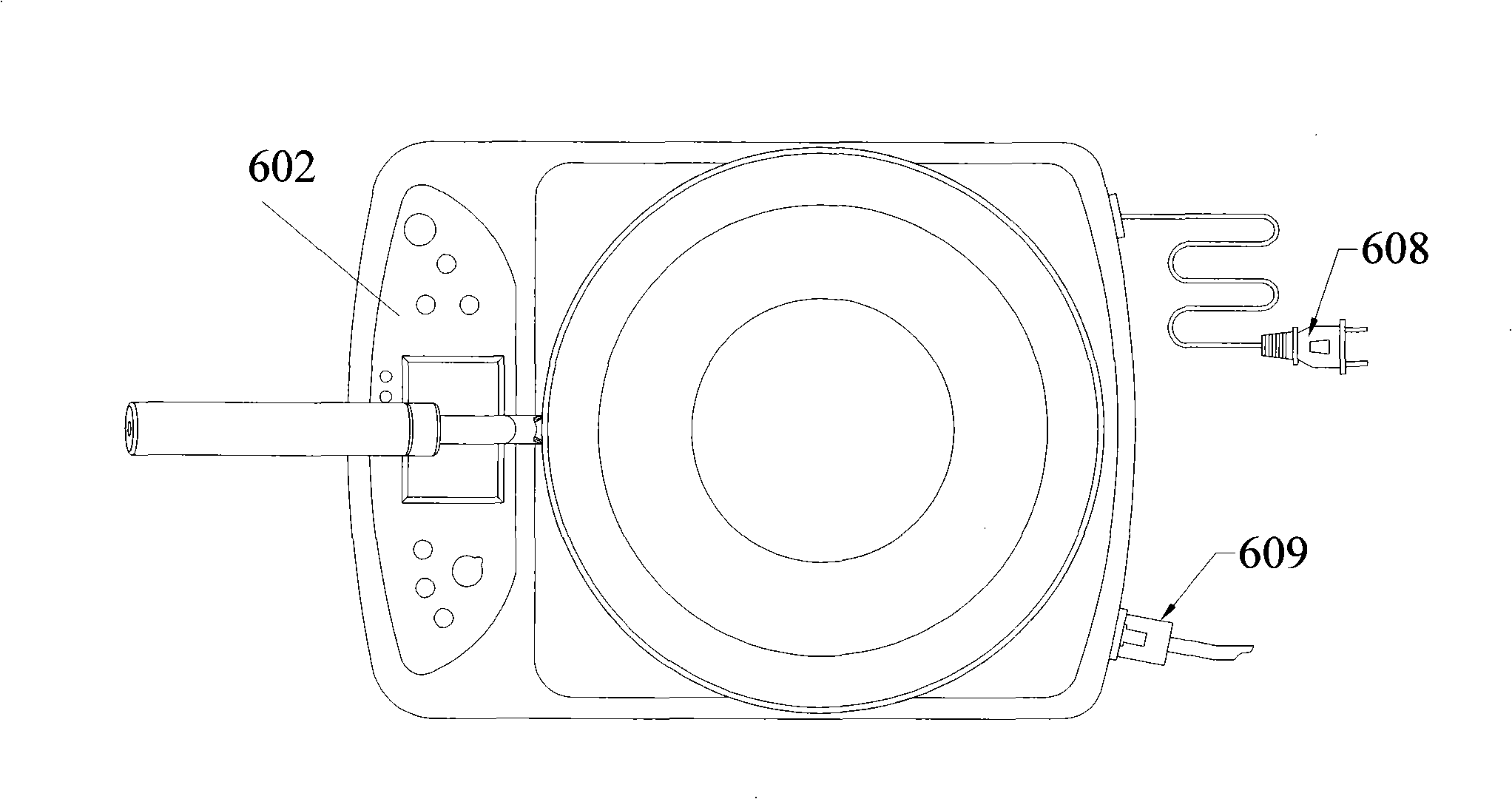

[0054] The gas stove includes a furnace body 701, an intelligent controller 6, an electric control valve 79, and an ignition circuit 706. The intelligent controller 6 is provided with a wireless communication module 4 and an antenna 5; the furnace body 701 also includes a gas hob 702 , air pipe 703, ignition needle 705, panel 602, network interface socket 609, power socket 608, the air pipe 703 connects the gas stove 702 and the electric control valve 79 in pipeline, and the ignition needle 705 is electrically connected with the ignition circuit 706 , the network interface socket 609 and the power socket 608 are electrically connected with the intelligent controller 6; the electric control valve 79 is electrically connected with the driving circuit 66 on the intell...

Embodiment 3

[0057] The stove shell of the wireless intelligent cooking device of this embodiment is provided with a network interface socket, and the network interface socket is connected to the Internet, a telephone line or other communication networks, and the network interface socket is connected to the intelligent controller. The network interface circuit is electrically connected; the intelligent controller of the stove includes a memory that can store various cooking method data.

[0058] A working method of a wireless intelligent cooking device, wherein, both the stove and the cooking utensil have a wireless communication module and an antenna, the temperature sensor signal on the cooking utensil is transmitted through the wireless communication module and the antenna, and the wireless communication module on the cooking utensil The module and antenna receive the temperature signal from the cooking utensils and transmit it to the intelligent controller. The intelligent controller co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com