Bearing tower type container of plastic anti-corrosive liner

An anti-corrosion lining, tower container technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of unreasonable production and configuration, unreasonable cost performance, etc. Simple structure, improved anti-penetration ability, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

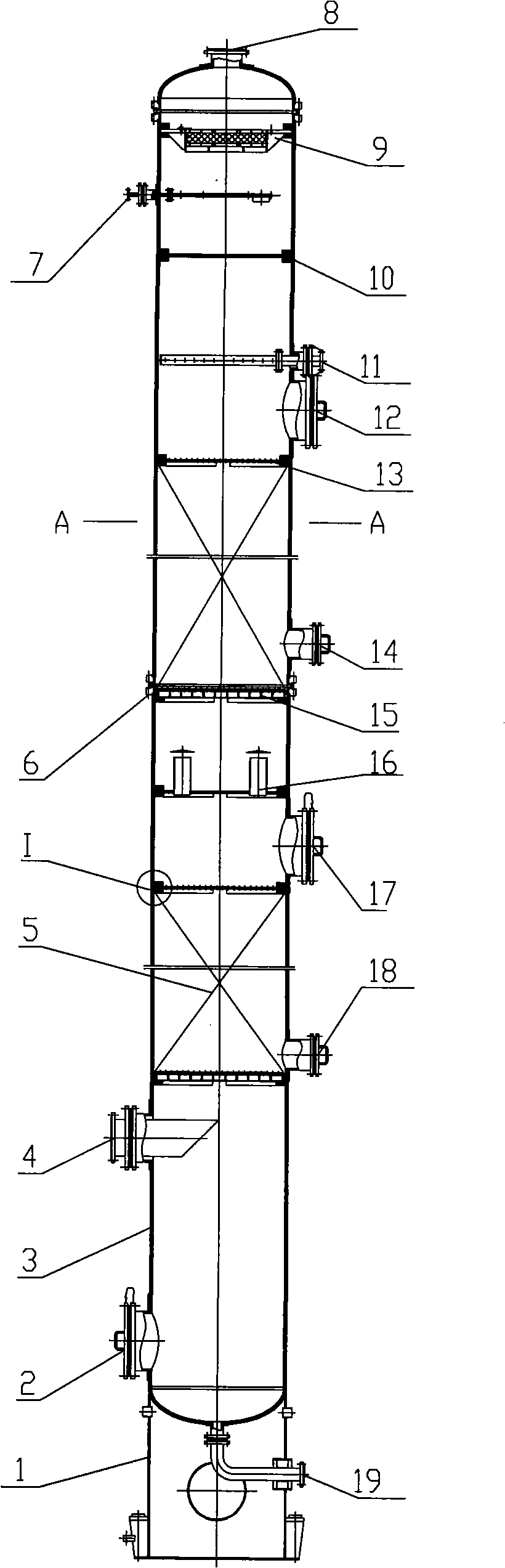

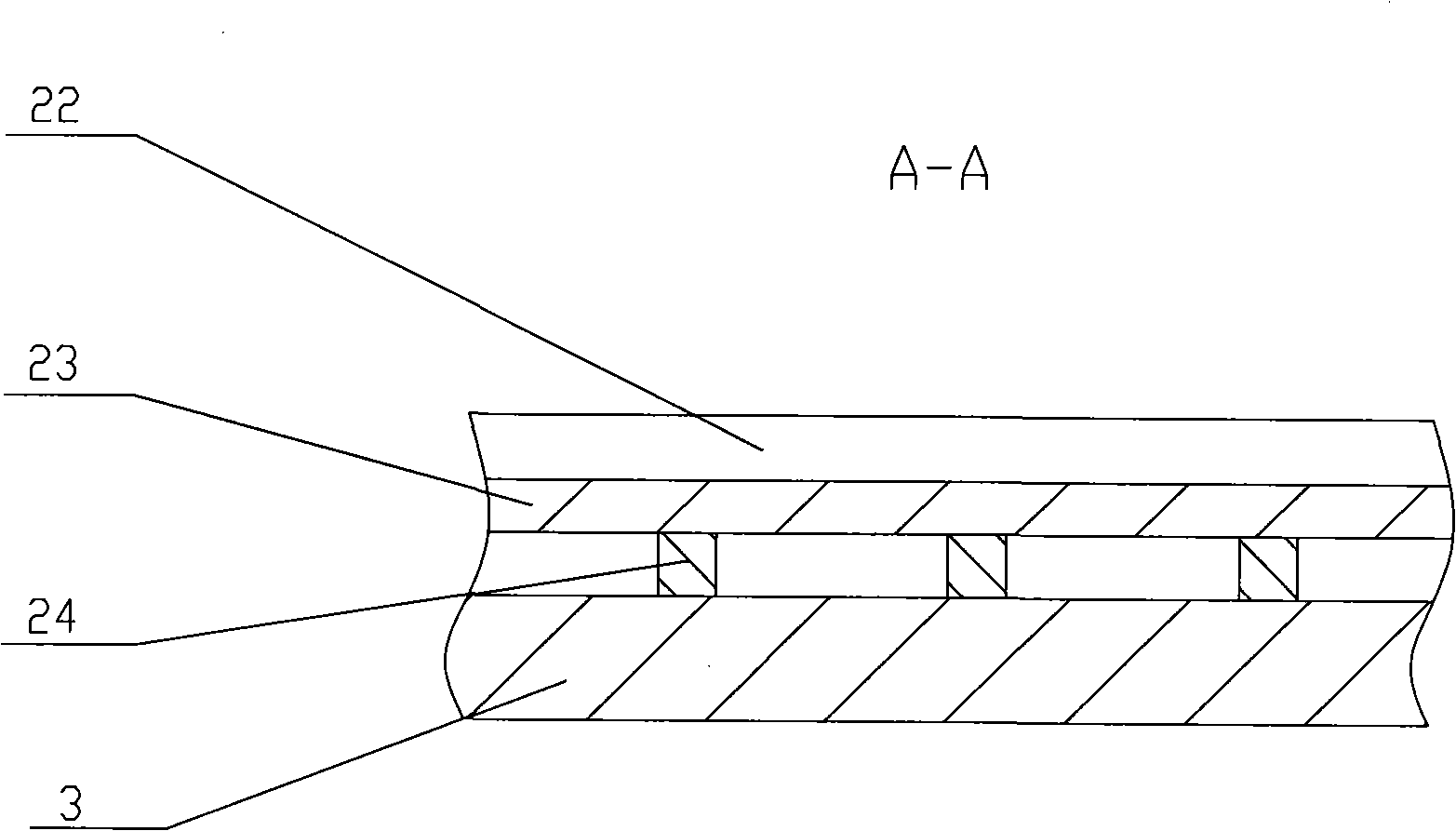

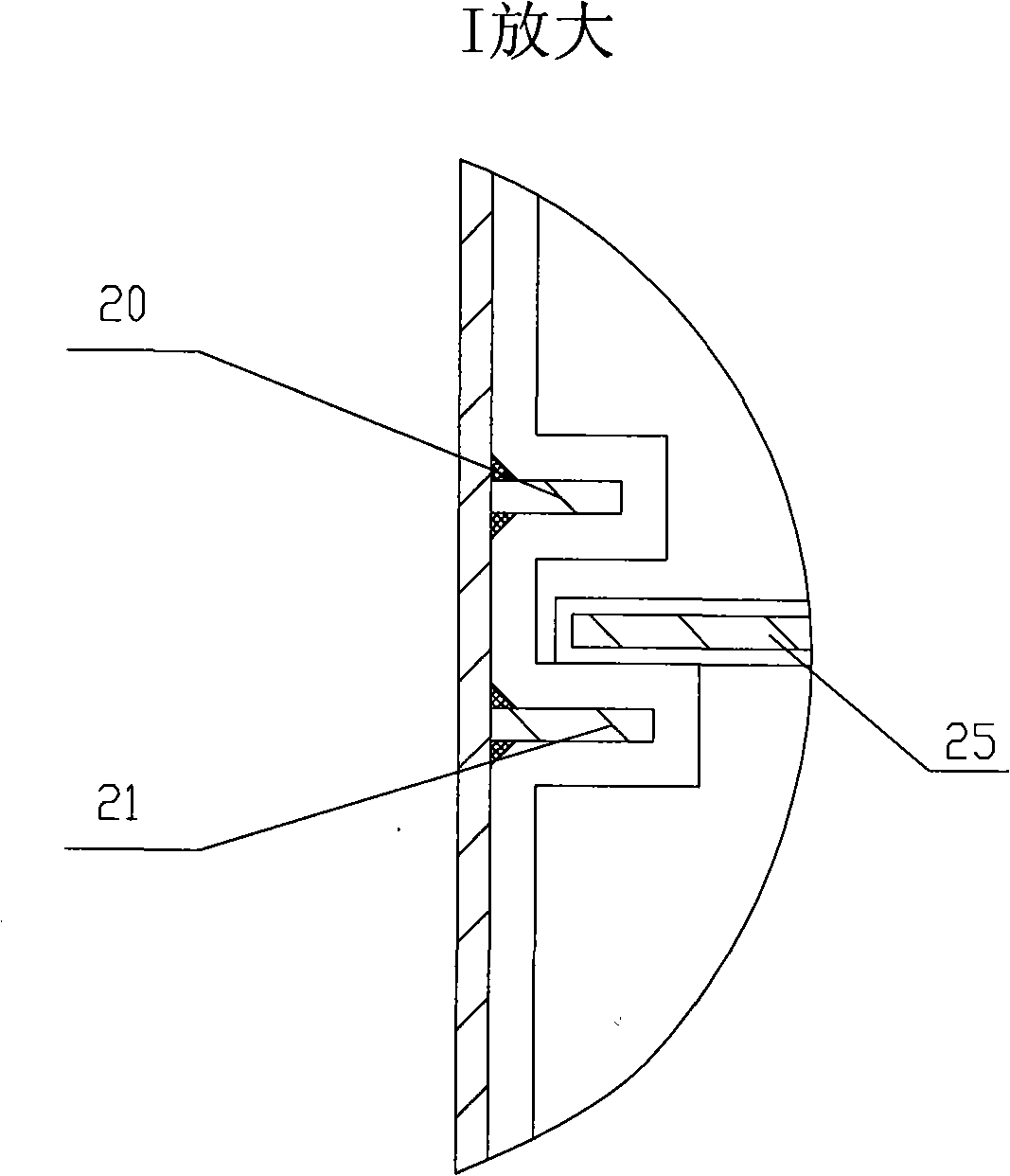

[0018] The present invention mainly consists of skirt seat 1, manhole 2, 12, 17, pressure tower body 3, gas phase inlet and outlet 4, 8, packing 5, connecting flange 6, filtrate inlet 7, wire mesh demister 9, tray 10. Liquid inlet 11, packing pressure plate 13, deletion plate 15, subdivider 16, hand holes 14, 18, discharge port 19, upper support plate 20, lower support plate 21, plastic lining 22, expanded metal mesh 23 and reinforcement Rib 24 etc. are formed.

[0019] like figure 1 Shown: the present invention uses carbon steel as the pressure-resistant tower body 3, the pressure-resistant tower body 3 can be divided into several sections, and the connection flange 6 is used to connect as a whole. The skirt 1 is connected and fastened to the foundation ring, and the first manhole 2, the second manhole 12, the third manhole 17, the first hand hole 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com