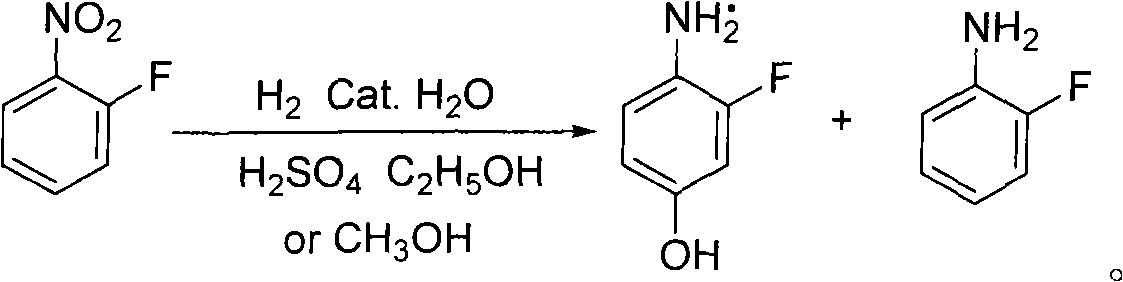

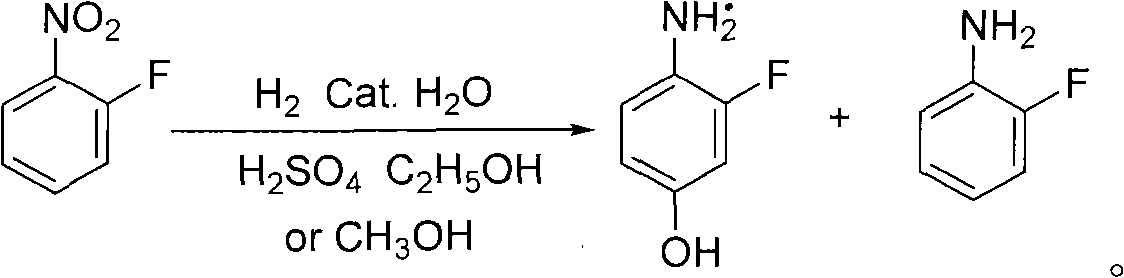

Process for 4- amino-3-fluorophenol

A kind of fluorophenol, the technology of the new process is applied in the field of producing 4-amino-3-fluorophenol, and can solve the problems such as incapability of industrialized production, limited, cumbersome handling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 28.2 grams of o-fluoronitrobenzene; 450 milliliters of deionized water; 27 grams of concentrated sulfuric acid; 20 milliliters of ethanol and 0.6 grams of 0.3% Pt / C into the reaction kettle. The kettle was sealed, and hydrogen was passed through the kettle until the pressure in the kettle reached 0.2 MPa to start stirring at a speed of 600 rpm. The temperature is increased to 120°C, the pressure is increased to 0.4 MPa, and the time is measured for 5.5 hours. After turning off the heating, pass water to lower the temperature to 25℃ and open the kettle. Pt / C in the reaction liquid is removed (recovered by filtration). The reaction liquid is obtained.

[0013] The reaction solution was extracted twice with 100 ml AcOEt, and the organic phase obtained by combining the two times was distilled under reduced pressure to obtain 1.2 g of unreacted raw material. The water phase was put into a 1000ml reaction flask and 200ml AcOEt was added. The pH was adjusted by adding alkali t...

Embodiment 2

[0018] Except that 20 ml of methanol and 0.6 g of 0.3% Pd / C are used, other conditions are the same as in Example 1. The result shows that the HPLC purity is 94%, and the yield is 61%.

Embodiment 3

[0020] Except that the reaction temperature is 30°C, other conditions are the same as in Example 1. The result shows that the conversion rate is low, HPLC purity: 65%, yield: 38%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com