Method, system and apparatus for remotely monitoring product use condition

A remote monitoring and product technology, applied in signal transmission systems, electrical signal transmission systems, instruments, etc., can solve the problems of poor controllability of the test process and low reliability of test data, so as to improve the accuracy of measurement and ensure reliability. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

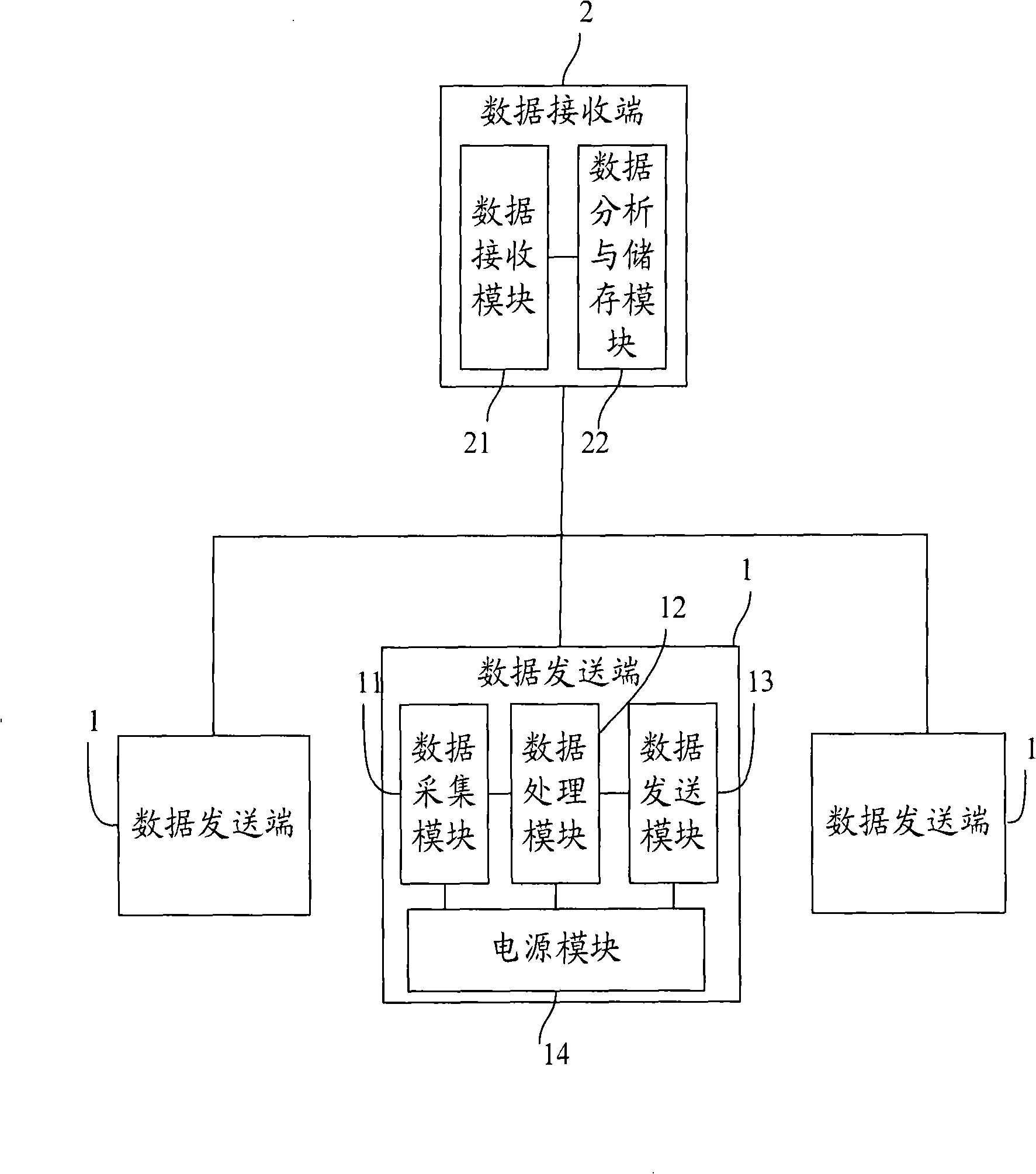

Embodiment 1

[0031] Containers for placing products such as medicines, cosmetics or health care products can be divided into two parts, a top cover and a main body, according to the usage conditions, and of course the top cover can not be used as required. If the product storage container adopts a top cover, it can use a common top cover, including rotary type, push type, etc. The main body of the product storage container can adopt an inner and outer double sandwich device, and the inner container is used to place the test product. The product can be solid or liquid, including powder, paste, cream, milk, gel, fluid, etc. A data sending terminal 1 is placed in the interlayer between the outer layer and the inner layer, wherein the size of the data sending terminal 1 can be adjusted according to the size and volume of the product storage container. In this embodiment, the data sending end 1 includes at least one weight sensor, wherein the weight sensor can be a common sensor, a micro sensor...

Embodiment 2

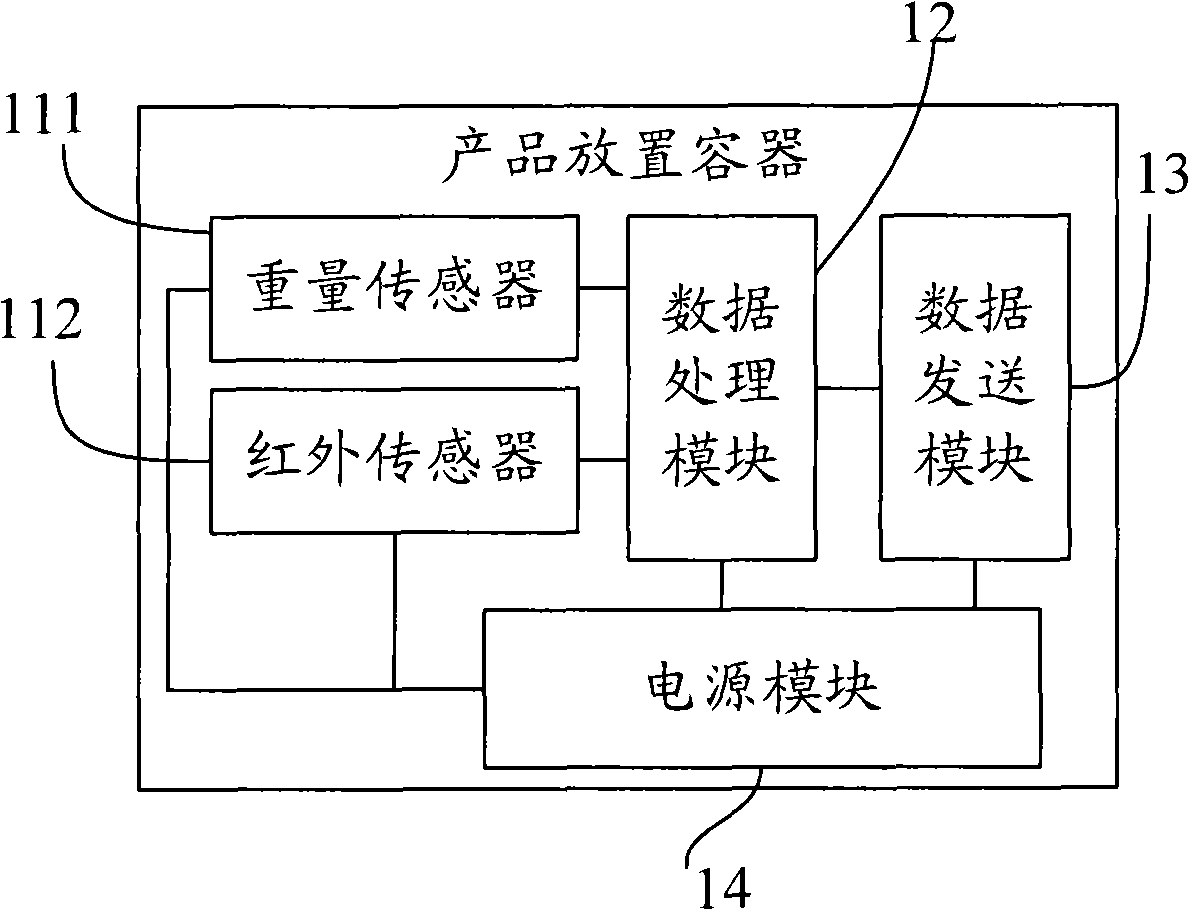

[0033] like figure 2 As shown, it is a structural diagram of the product storage container of the second embodiment of the present invention. Compared with the first embodiment, this embodiment not only includes a weight sensor 111 arranged under the inner container for placing the test product, but also includes an infrared sensor 112 , the infrared sensor 112 can be arranged on one side of the interlayer of the main body, and a transparent glass window can be arranged on the top of it, such as a small transparent glass window of about 1mm can be set, and the user can open it every time through the small transparent glass window. After the product is placed on the top cover of the container, the infrared sensor 112 can perceive and generate a corresponding trigger signal. Of course, the bottle mouth of the product placement container can also be fully transparently designed. Similarly, the infrared sensor 112 can also be arranged on the top cover of the product storage cont...

Embodiment 3

[0035] In this embodiment, the top cover of the product storage container is a push-type top cover. Compared with the first embodiment, this embodiment not only includes a weight sensor arranged under the inner layer container for placing the test product, but also includes A flow / pressure sensor arranged in the push-type top cover. Also in this embodiment, the data collected by the weight sensor and the flow / pressure sensor are mutually verified and compared to avoid data leakage due to abnormal use. detection or false detection. In this embodiment and the second embodiment, the weight sensor and the flow / pressure sensor, and the combination of the weight sensor and the infrared sensor are used respectively, of course, the combination of the infrared sensor and the flow / pressure sensor can also be used, or the above three sensors can be used in combination at the same time The way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com