ACF paste device and flat panel display

A technology for pasting devices and substrates, which is applied in the directions of identifying devices, instruments, and assembling printed circuits with electrical components, which can solve the problems of large-scale devices and large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

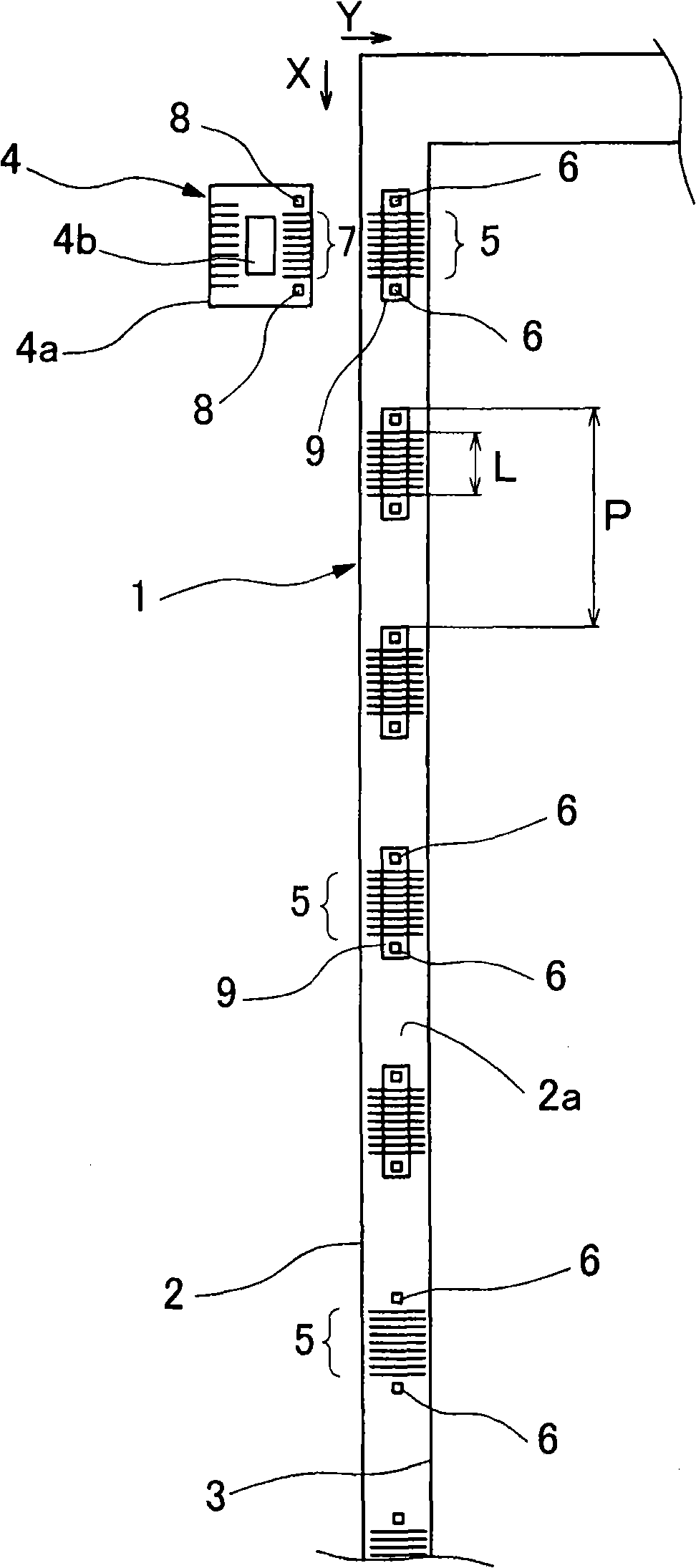

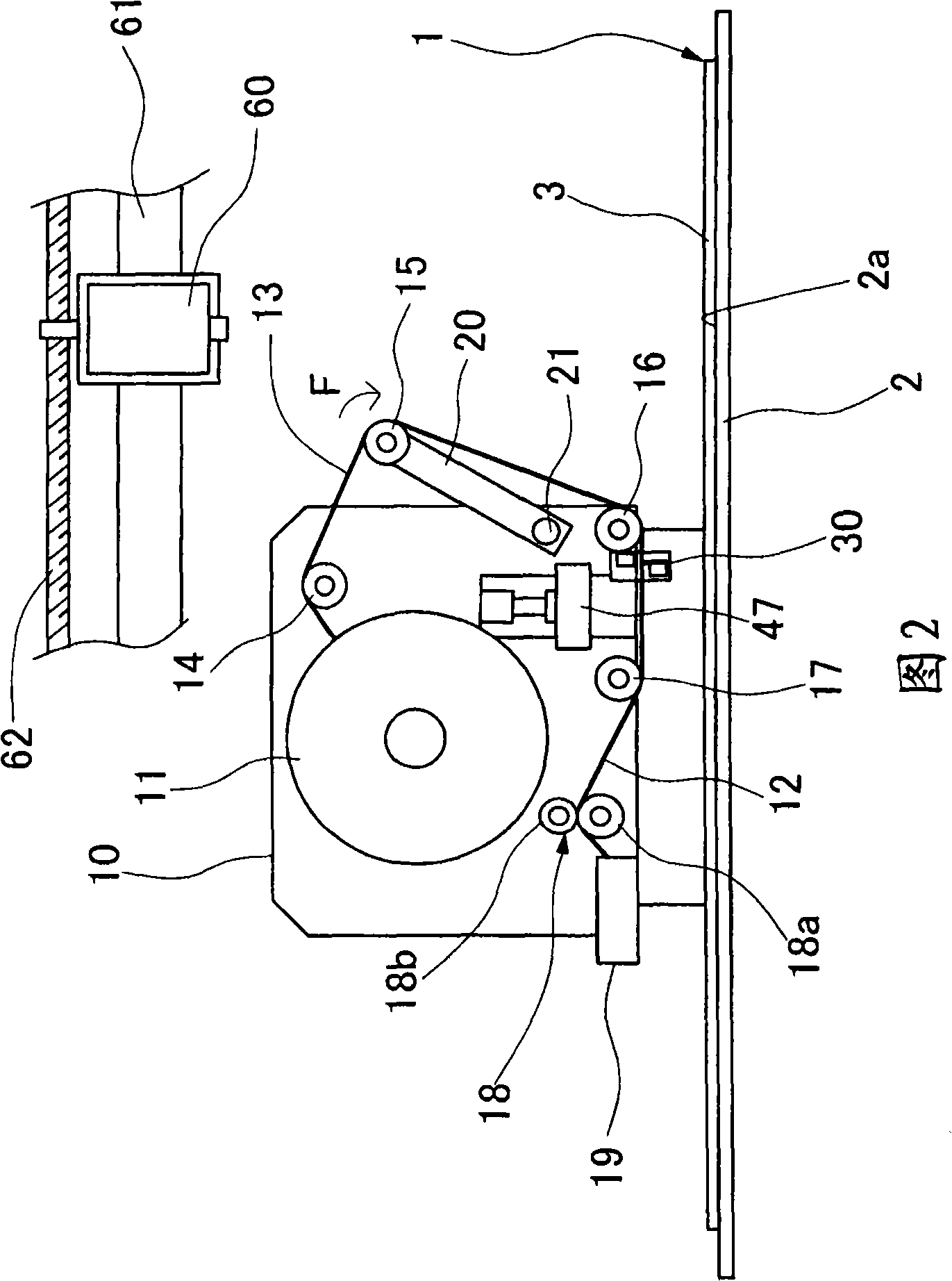

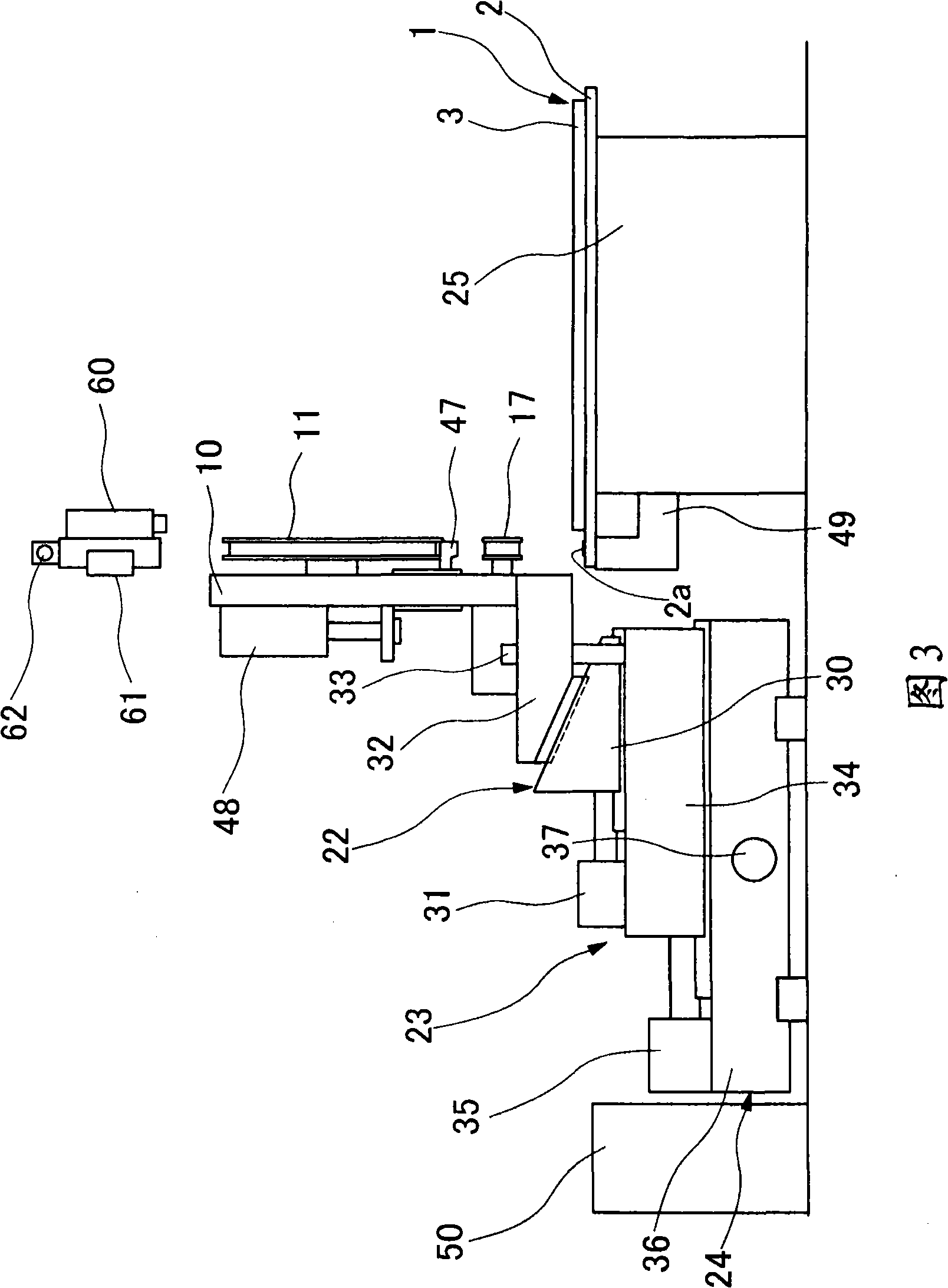

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 A liquid crystal panel is shown as an example of a substrate on which ACF is pasted, and a drive circuit including TCP mounted on the substrate by TAB is shown as an example of a semiconductor circuit element mounted on the ACF. In addition, the substrate is not limited to a substrate constituting a liquid crystal panel, and may be a printed circuit board or the like, and what is mounted on the substrate is not limited to a drive circuit, and may be a circuit electrically connected through an ACF.

[0031] figure 1 Among them, 1 is a liquid crystal panel. The liquid crystal panel 1 is composed of a lower substrate 2 and an upper substrate 3. Both the lower substrate 2 and the upper substrate 3 are made of glass thin plates, and liquid crystal is sealed between the two substrates 2 and 3. The lower substrate 2 protrudes from the upper substrate 3 by a predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com