Method for preparing liquid sodium silicate by one-step liquid phase reaction

A liquid-phase reaction, sodium silicate technology, applied in the direction of silicate, alkali metal silicate, etc., can solve the problems of inability to chemically synthesize products, difficult control, and inability to produce finished products, and achieves easy control of investment and production scale, and equipment. Strong applicability and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

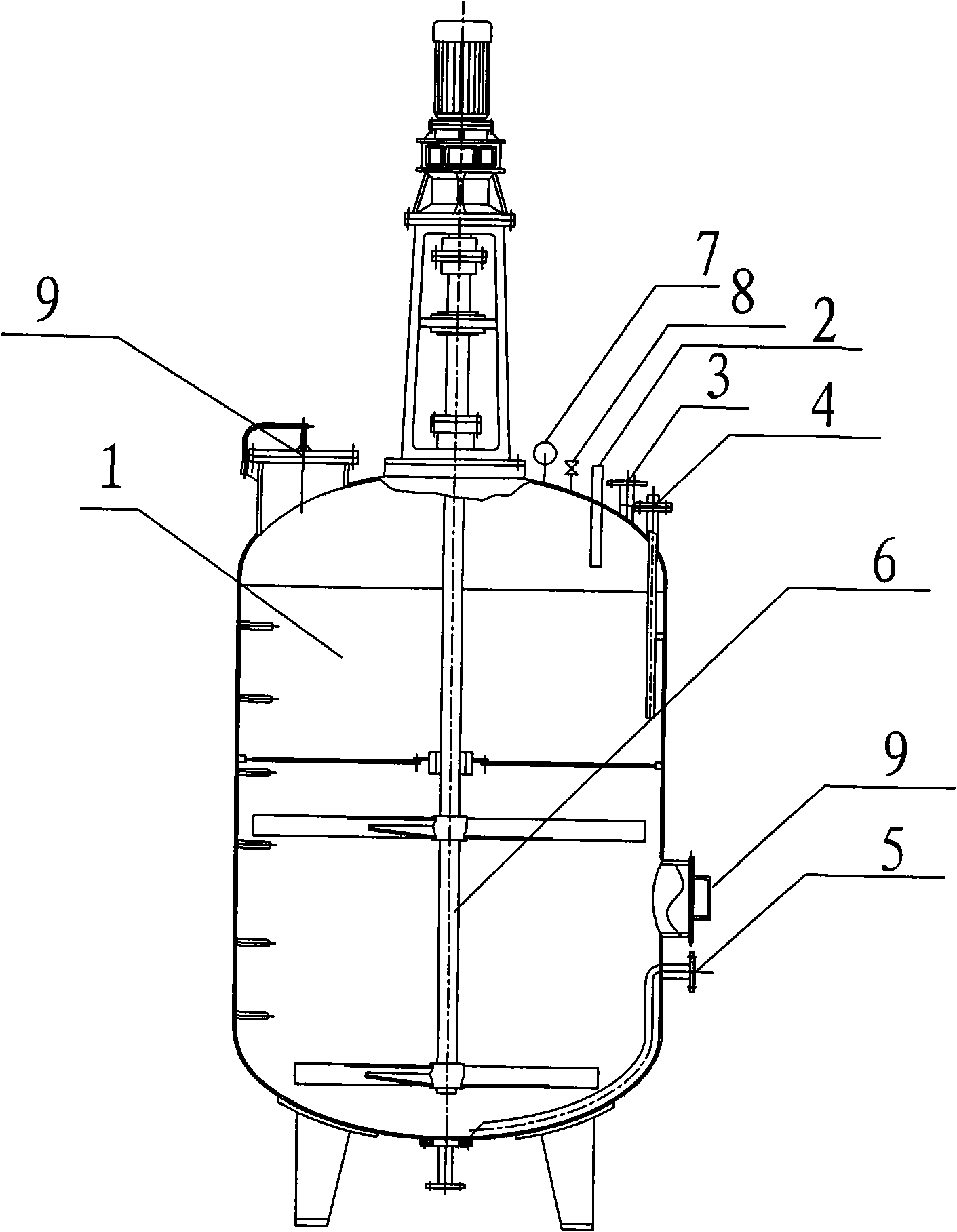

Image

Examples

Embodiment 1

[0038] Put the SiO in the ingredient pot 2 The No. 7 quartz sand produced in Anhui with a content of more than 99% and 30% liquid caustic soda are mixed at a molar ratio of 2.45:1, and the mixture is pumped into the liquid phase reaction pot that has been stirred under the stirring state, and steam is directly passed into it for heating. When the pressure in the pot reaches 0.65Mpa, stop the steam, automatically increase the pressure to 0.7Mpa, fully react for 4 hours, take samples for analysis, when the modulus reaches 2.4M, discharge the steam in the reaction pot through the vent pipe to reduce the pressure, and the discharged steam is passed to Another reaction pot is used for preheating. After the pressure drops to 0.3Mpa, it is put into a suction filter barrel for vacuum filtration, and the obtained filtrate is 2.4M liquid sodium silicate with a purity of more than 99.0%.

Embodiment 2

[0040] Put the SiO in the ingredient pot 2 The No. 7 quartz sand produced in Anhui with a content of more than 99% and 30% liquid caustic soda are mixed at a molar ratio of 3.25:1, and the mixture is pumped into the liquid phase reaction pot that has been stirred under stirring state, and steam is directly passed into it for heating. When the pressure in the pot reaches 0.65Mpa, stop the steam, automatically increase the pressure to 0.7Mpa, fully react for 5.5 hours, take samples and analyze, the modulus reaches 3.2M, release the steam in the reaction pot through the vent pipe to reduce the pressure, and the released steam is passed into another A reaction pot is used for preheating. After the pressure drops to 0.3Mpa, it is put into a suction filter bucket for vacuum filtration. The suction filtrate material is 3.2M liquid sodium silicate with a purity of more than 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com