Heat-resistant integral casting foundation for large-sized industrial kiln and forming method thereof

A large-scale industrial and kiln technology, applied in the field of large-scale metallurgical kilns, can solve the problems of unstable material structure and performance, poor strength, etc., and achieve the effects of high strength, good cost performance and reduced diameter

Active Publication Date: 2010-09-08

李朝侠

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

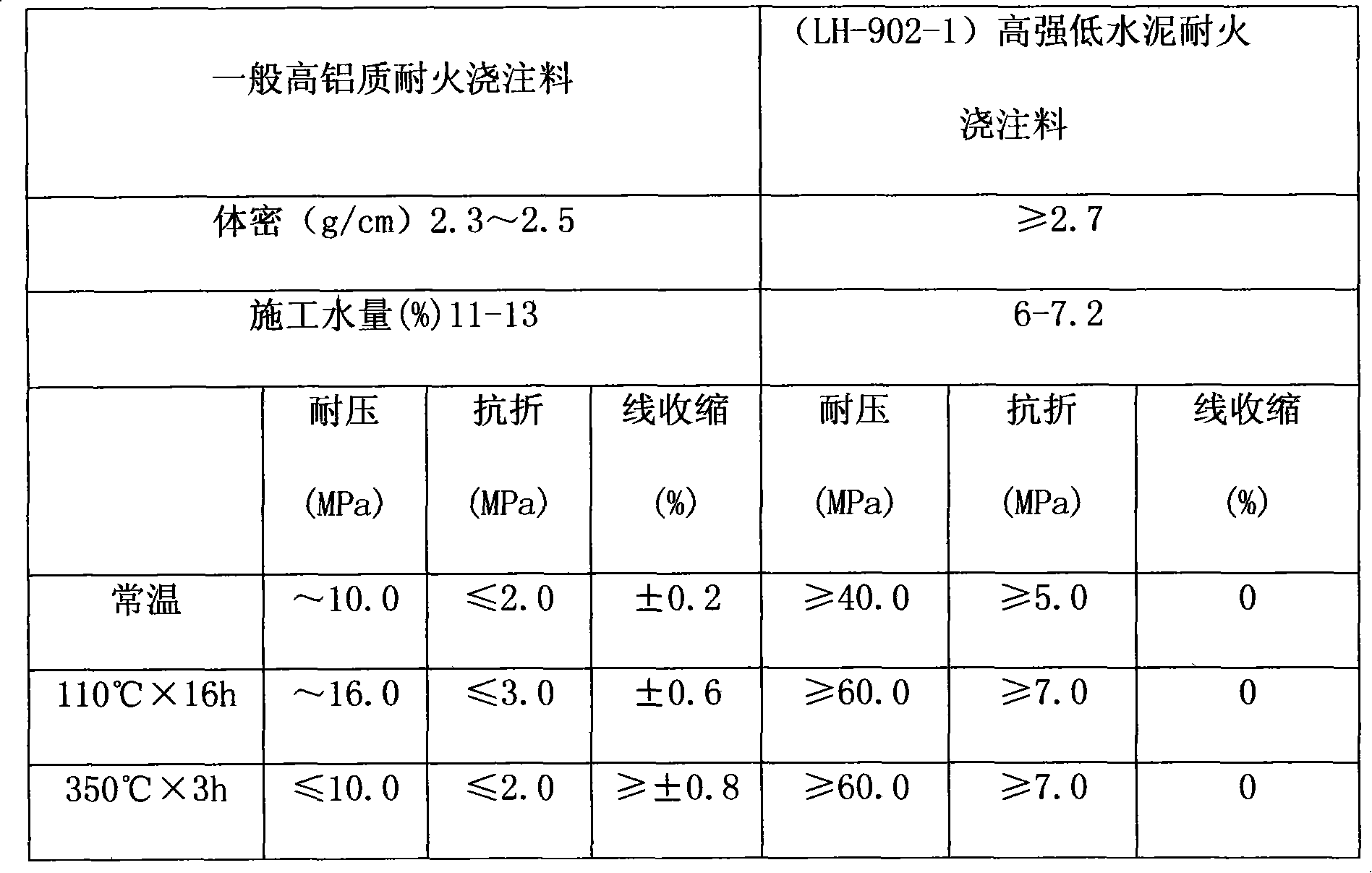

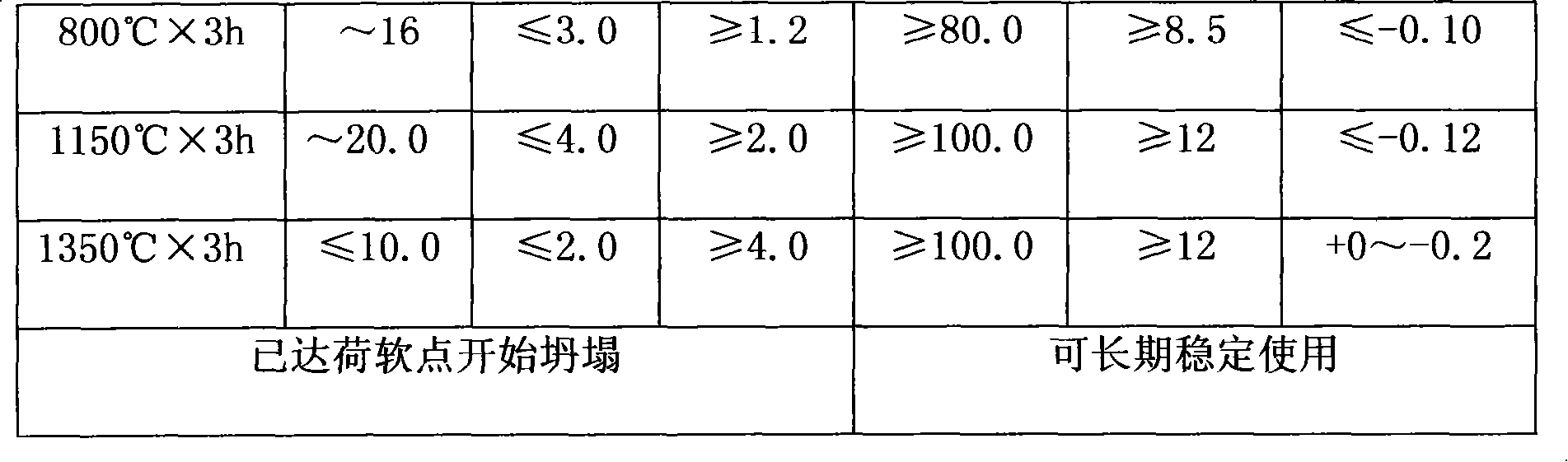

Therefore, due to poor strength and unstable material structure performance, ordinary refractory concrete cannot be used as load-bearing concrete, and can only be used as refractory isolation lining.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

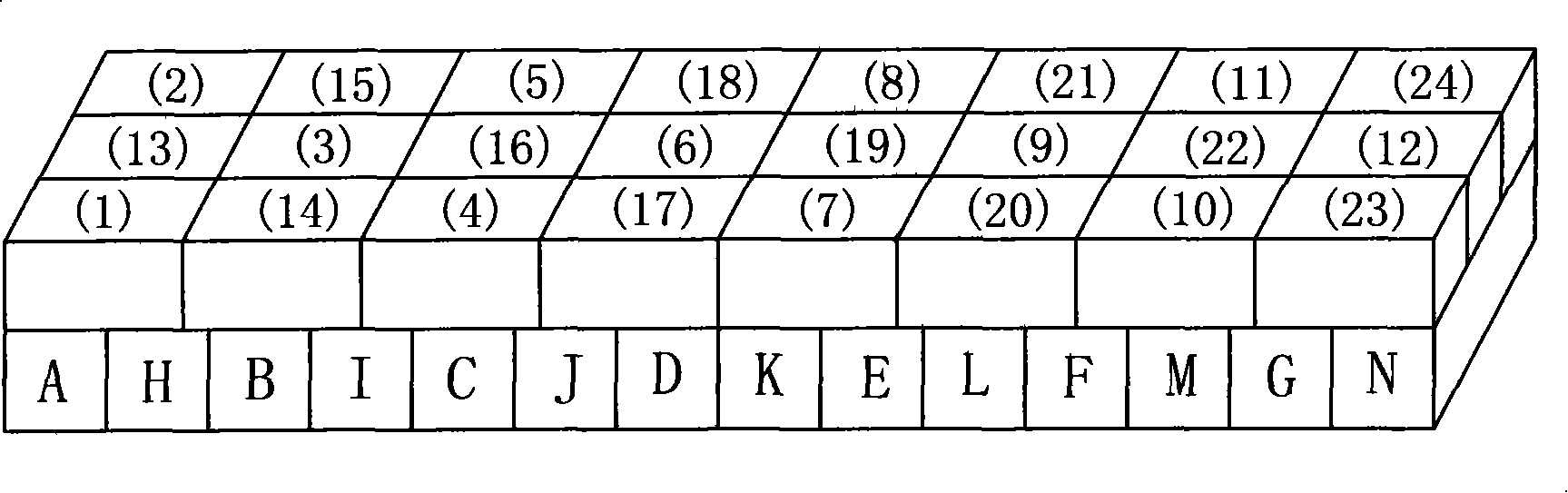

The invention discloses a heat-resisting and integral-casting basis of a large industrial furnace and a forming method thereof, which adopts amorphous cast refractory materials and heat-resisting stainless steel bars which are combined closely to form a supporting body with gap flexibility and dual-intensity, and a heat-resisting stainless steel bar skeleton is coated with asphalt paint with the thickness of between 1 and 2mm or coiled with fiber paper with the thickness of between 1 and 2mm. The forming method adopts the continuous casting after layering, segmentation and partitioning and reserves a dilatation joint, the temperature is no less than 10 DEG C when in construction in winter, and the temperature for heating the agitating water for the casting material is between 15 and 25 DEG C. The forming method has advantages of greatly reduced basic bar arrangement density of a bulky fireproof concrete compared with the general design, reduced diameter of the screw-threaded steel, low cost, safety and reliability, rather strong disaster tolerance, and being capable of bearing the scouring of hundreds of tons to thousands of tons of high temperature metal liquid and continual thermal shattering effect and mechanical vibration load.

Description

technical field The invention relates to a large-scale metallurgical kiln, in particular to a large-scale metallurgical kiln integrally casting an unshaped refractory castable foundation and a forming method thereof. Background technique The structure of the furnace bottom of the large-scale metallurgical industrial furnace is distinguished by the relationship between the furnace bottom and the furnace foundation, that is, it is divided into an overhead furnace bottom and a solid furnace bottom. Taking the continuous operation of the copper smelting reverberatory furnace as an example, the furnace bottom is directly built on the heat-resistant concrete foundation, and the required temperature resistance of the heat-resistant concrete foundation is above 850 °C. A big difference between the refractory concrete and the conventional concrete as the foundation of the kiln is that the steel structure support of the ordinary refractory concrete is a layered mechanical structure, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/66

Inventor 李朝侠黄河

Owner 李朝侠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com