Method for using diesel oil caustic sludge wastewater for diesel oil caustic washing

A technology of alkali residue wastewater and diesel oil, applied in the direction of refining with alkaline aqueous solution, etc., can solve problems such as high energy consumption and environmental pollution, and achieve the effects of improving economic benefits, making full use of it, and relieving environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

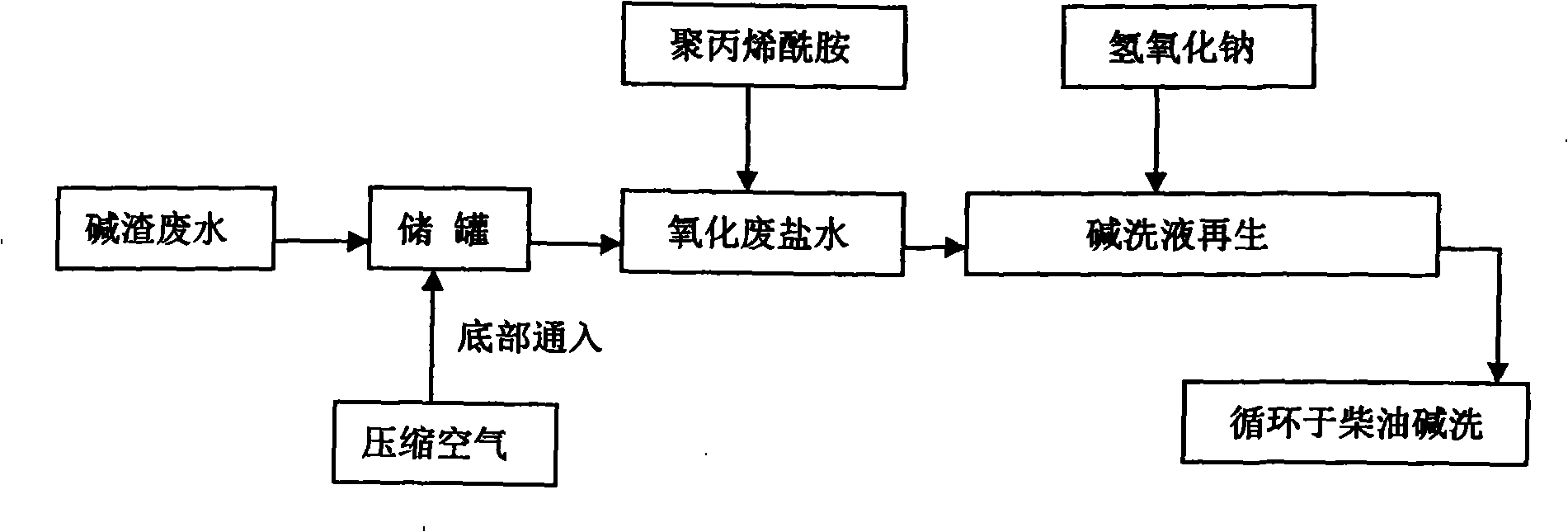

Image

Examples

Embodiment 1

[0009] Put the diesel alkali slag wastewater into the storage tank, let it stand for 2 hours to settle and discharge the solid waste, pass excessive compressed air from the bottom of the storage tank to fully mix the alkali slag and air, oxidize the organic and inorganic sulfides in it to sulfate, and then Add 2ppm of polyacrylamide to it, stir and mix evenly, then add NaOH to make Na 2 SO 4 The 3% NaOH solution is recycled for alkaline washing process.

Embodiment 2

[0011] Put the diesel alkali slag wastewater into the storage tank, let it stand for 2 hours to settle and discharge the solid waste, pass excessive compressed air from the bottom of the storage tank to fully mix the alkali slag and air, oxidize the organic and inorganic sulfides in it to sulfate, and then Add 5ppm of polyacrylamide to it, stir and mix evenly, then add NaOH to make Na 2 SO 4 The 3% NaOH solution is recycled for alkaline washing process.

Embodiment 3

[0013] Put the diesel alkali slag wastewater into the storage tank, let it stand for 2 hours to settle and discharge the solid waste, pass excessive compressed air from the bottom of the storage tank to fully mix the alkali slag and air, oxidize the organic and inorganic sulfides in it to sulfate, and then Add 1ppm of polyacrylamide to it, stir and mix evenly, then add NaOH to make Na 2 SO 4 The 3% NaOH solution is recycled for alkaline washing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com