Special fine sand high-strength high-performance concrete ultra-high pumping construction method

A high-performance concrete and construction method technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of large specific surface area, high void ratio, low water consumption, etc., to reduce cement consumption, The effect of convenient operation and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in combination with specific embodiments.

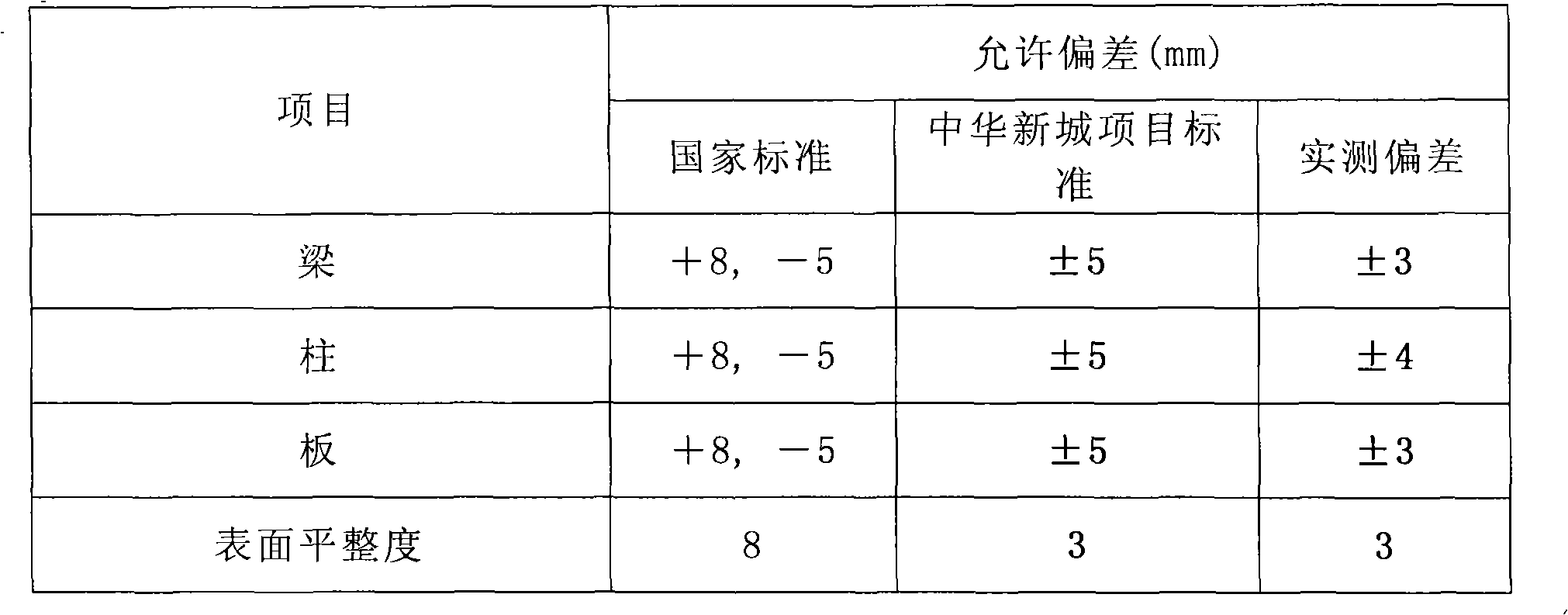

[0048] Take the construction of the main structure of reinforced concrete over-limit super high-rise in Chongqing Zhonghua New City as an example.

[0049] 1. Project overview

[0050] The Chongqing Zhonghua New City project is the largest conjoined public building project in my country. The construction area reaches 560,000 square meters, including three floors underground, podium buildings with 5-6 floors above the ground, and 8 towers in Buildings 3-10. field and equipment rooms; the podium building is a multi-functional commercial area, the 3#, 4#, 5#, 8#, 9#, 10# towers are high-end residential buildings with 27-30 floors, and the 6# building is a 37-story high-end hotel apartment office building, 7# building is a 54-story (structure height of 232 meters) office building and a five-star hotel. This project has the characteristics of large overall scale, super high s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com