Oil well chemical gorge and disgorge yield increasing and inverse direction regulating block connection working process

A chemical and process technology, applied in the field of oil well chemical huff-puff increase production and reverse plugging adjustment and combined operation process, can solve the problems of insufficient enhanced oil recovery and inability to improve the efficiency of injection water washing oil, so as to extend the production cycle and improve oil recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the performance evaluation of above-mentioned chemical reagent:

[0022] 1. Performance evaluation of water plugging profile control agent:

[0023] 1. The influence of PH value on the gelling performance:

[0024] The aqueous solution formulated as a water plugging profile control agent was tested at a temperature of 60°C to investigate the effect of pH on the gelling performance of the water plugging profile control agent. The data in Table 1 shows that as the pH value increases, the gelation time prolongs and the gel strength remains basically unchanged.

[0025] The influence of PH value on gel-forming performance Table 1

[0026] PH value

Gel forming time (h)

Gel strength (MPa)

6.0

1.9

4.2

6.5

3.7

4.2

7.0

6.5

4.0

7.5

9.8

4.0

8.0

12.4

3.9

[0027] 2. The influence of temperature on gelation properties:

[0028] As the tem...

Embodiment 2

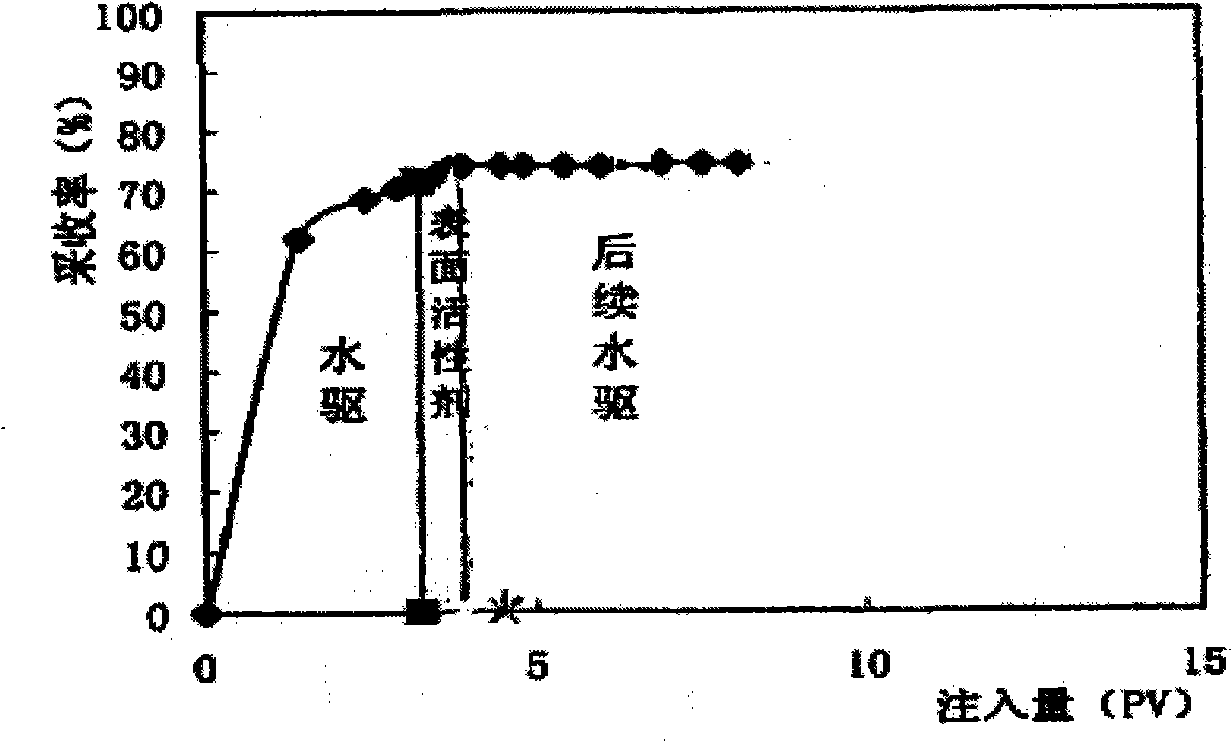

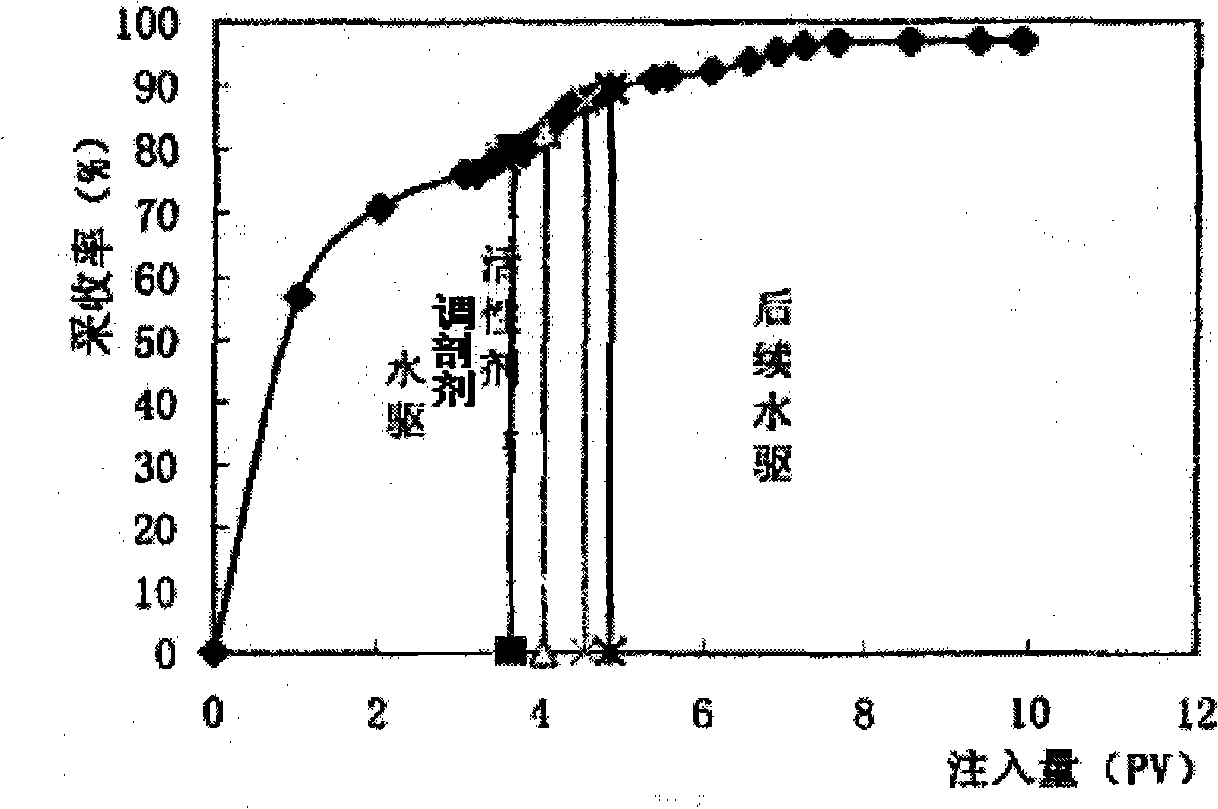

[0048]Example 2. Using parallel sand-packing pipe model flooding simulation test, the feasibility of combining reverse profile control and active agent flooding to improve recovery was investigated, and then the injection of active agent and injection of surface active agent after reverse profile control were compared and studied. The oil recovery mechanism of active agent combined with reverse profile control (water shutoff) was analyzed based on the effect of active agent on enhancing oil recovery.

[0049] 1. Parallel sand filling pipe core parameters:

[0050] Table 6

[0051]

[0052] 2. Experimental plan:

[0053] (1) Surfactant enhanced oil recovery experimental scheme: the concentration is 0.2% HLS-08 aqueous solution 0.5PV, and the HLS-08 surfactant is compounded with sodium petroleum benzenesulfonate and fatty acid alkanolamide in a ratio of 1:1 made.

[0054] (2) Experimental plan for joint technology of active agent and reverse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com