Side combustion type rotor internal combustion engine

A rotor internal combustion engine and combustion type technology, which is applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of low output power, difficulty in cooling, and small torque of rotor internal combustion engines, so as to reduce the number of parts and improve mechanical performance , The effect of simplifying the lubrication system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

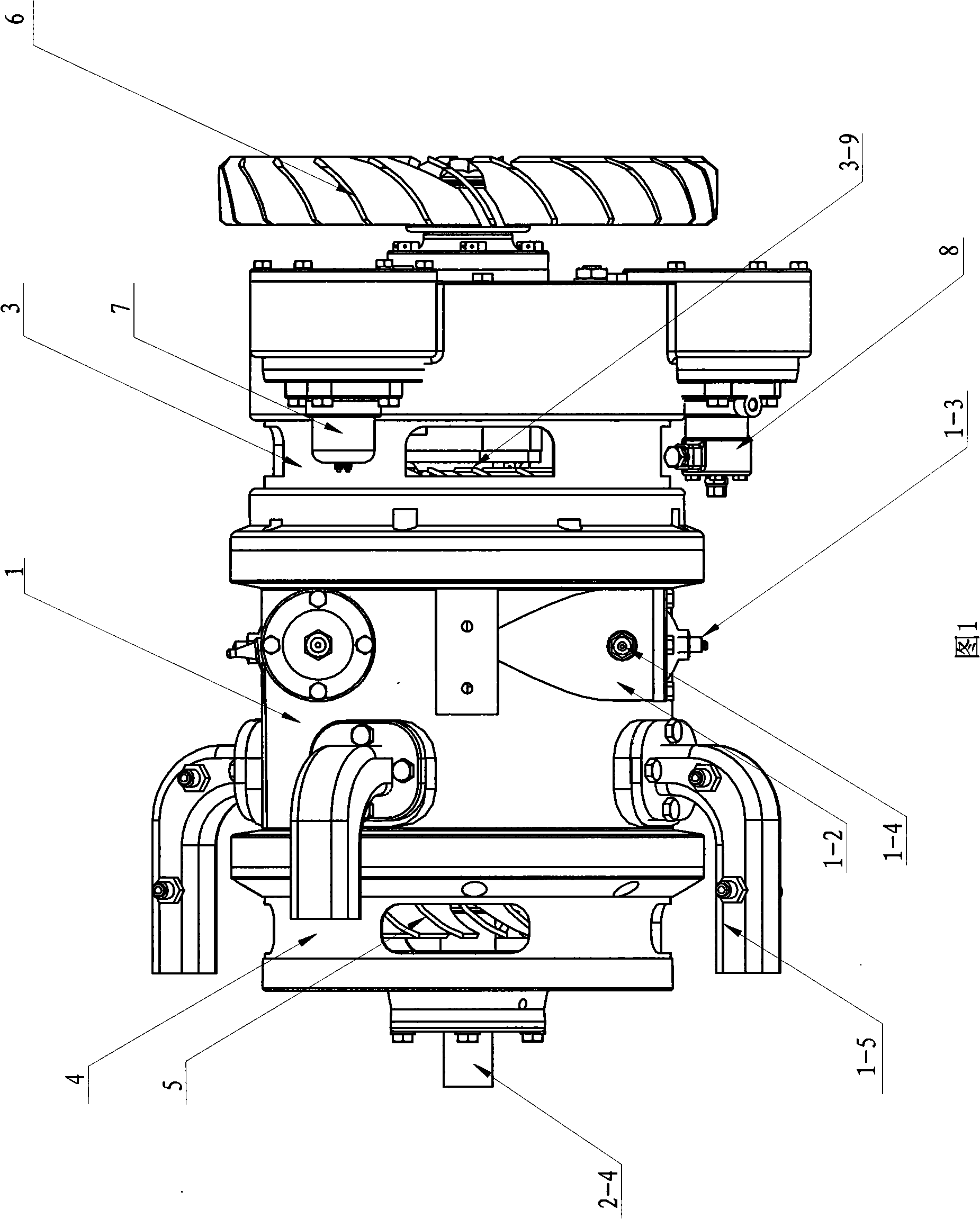

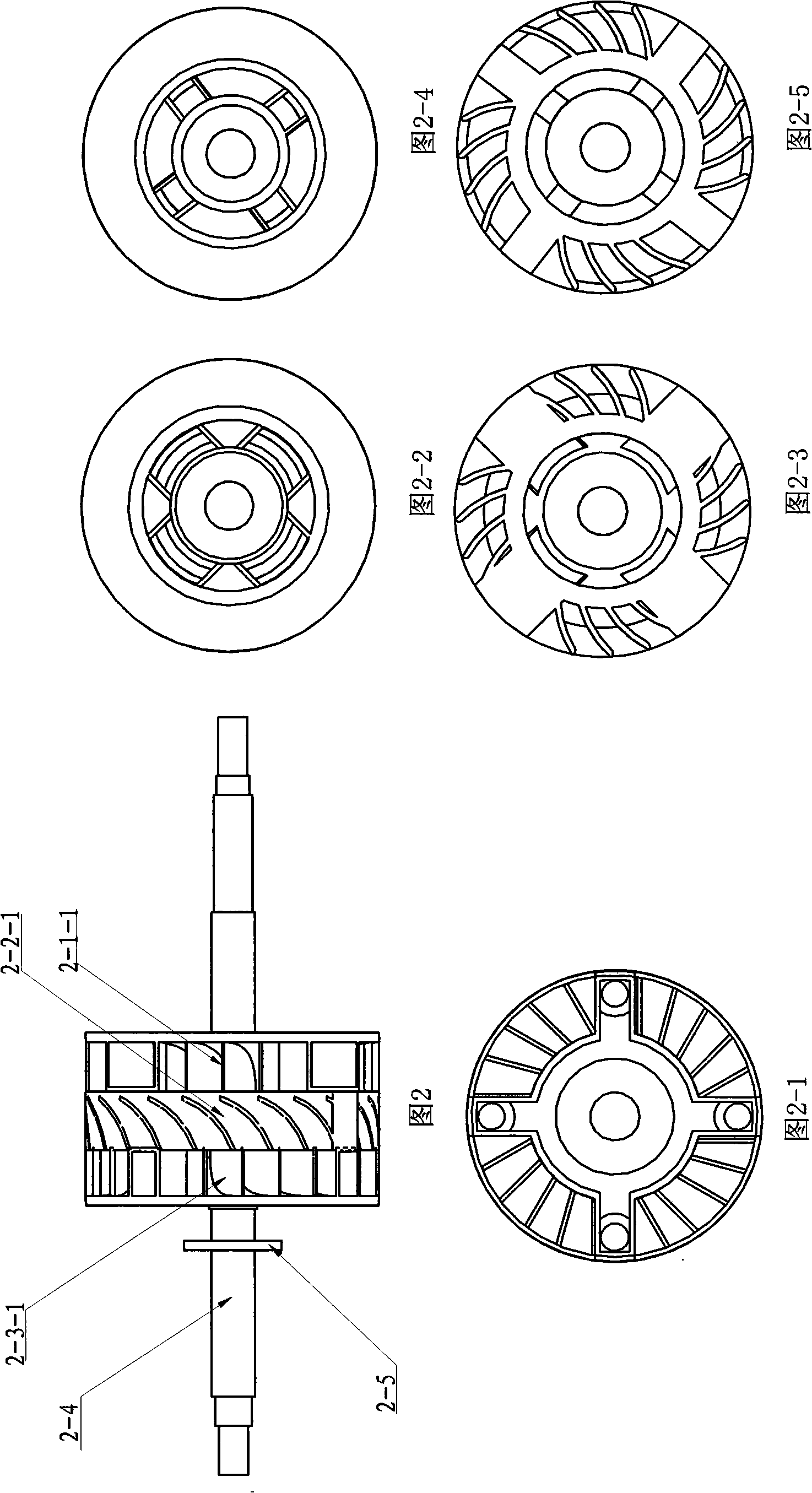

[0027] Referring to accompanying drawings 1-shown in Figure 6, the side combustion type rotor internal combustion engine of preferred embodiment of the present invention is mainly by internal combustion engine body, internal combustion engine rotor wheel set and power take-off shaft, air supply / timing transmission mechanism, rear end cover, and fuel System, ignition system, gas distribution, exhaust, cooling system, gas distribution, oil supply (combustible gas), ignition timing system, lubrication system consists of several parts:

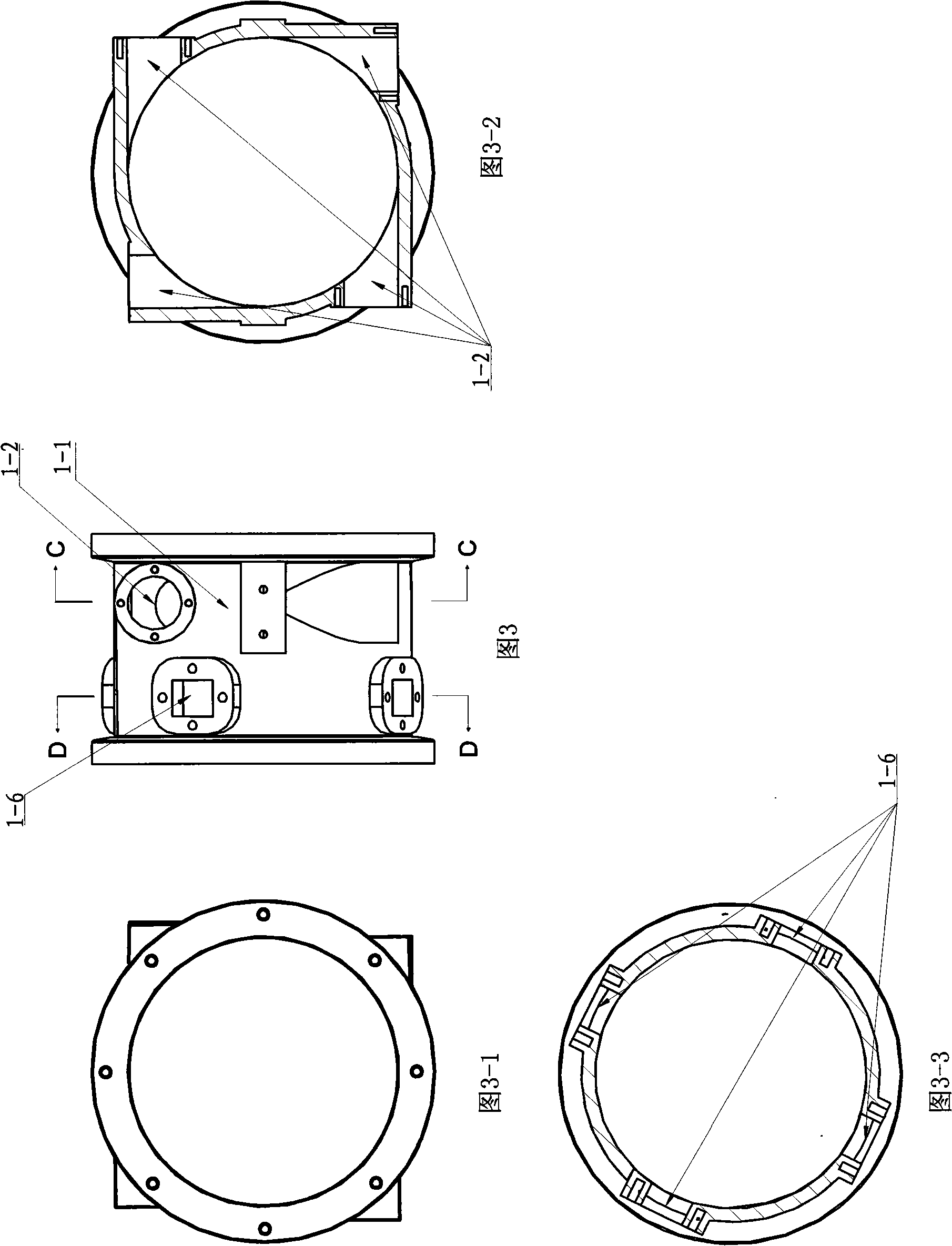

[0028] 1. Internal combustion engine body (see Figure 1, Figure 3, Figure 3-1, Figure 3-2, and Figure 3-3): it is the main body of the internal combustion engine. It is mainly composed of a body main body 1-1, a combustion chamber 1-2, and an exhaust hole 1-6. The body 1-1 is provided with four combustion chambers 1-2 and corresponding four exhaust holes 1-6 which are tangent to the circular body and distributed symmetrically. The front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com