High temperature furnace inner video image temperature measuring system

A video image and high-temperature furnace technology, applied in the field of temperature measurement system, can solve the problems of expensive equipment, achieve the effect of improving the quality of materials processing, reducing the generation of pollutants, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the drawings.

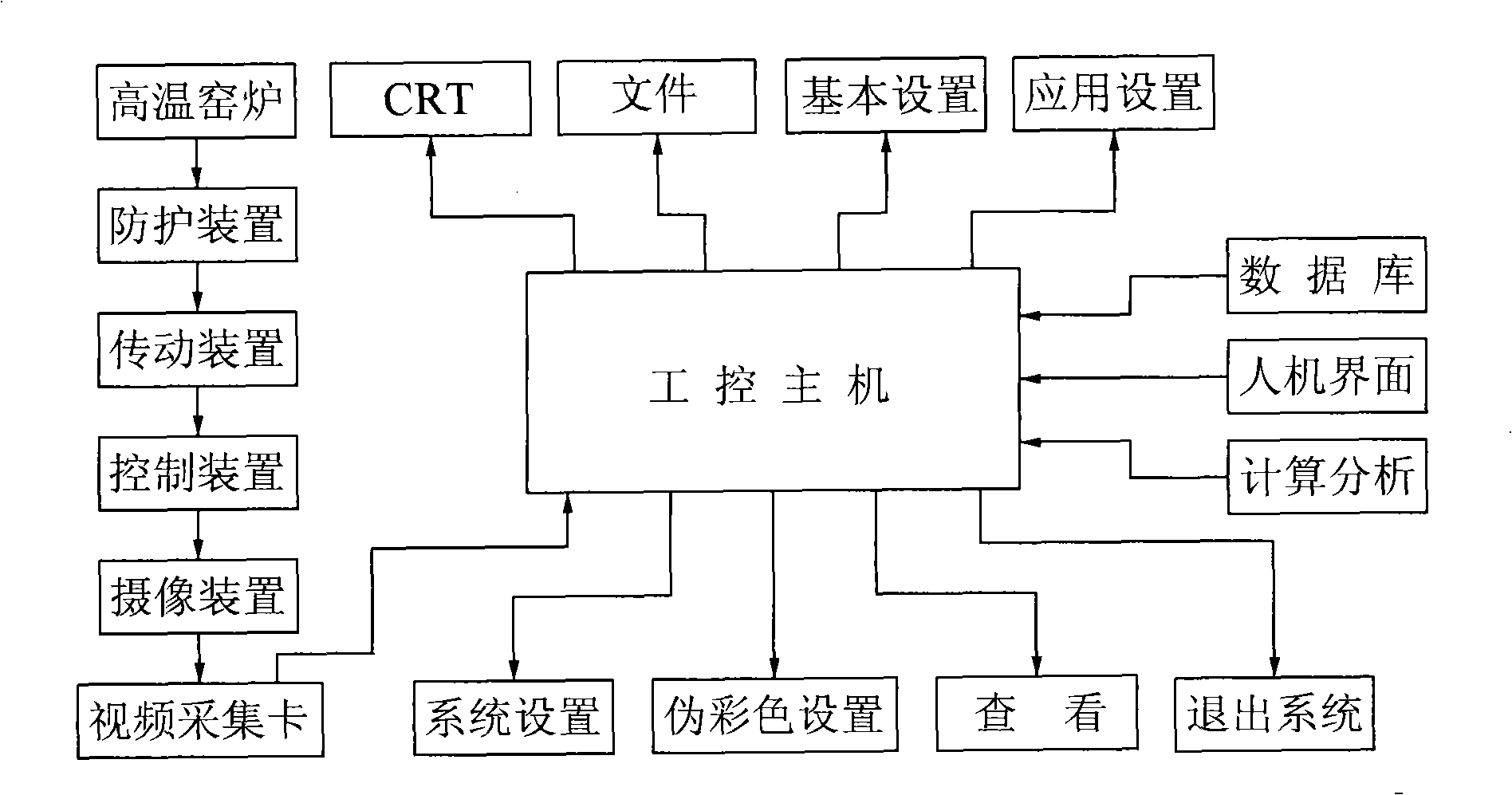

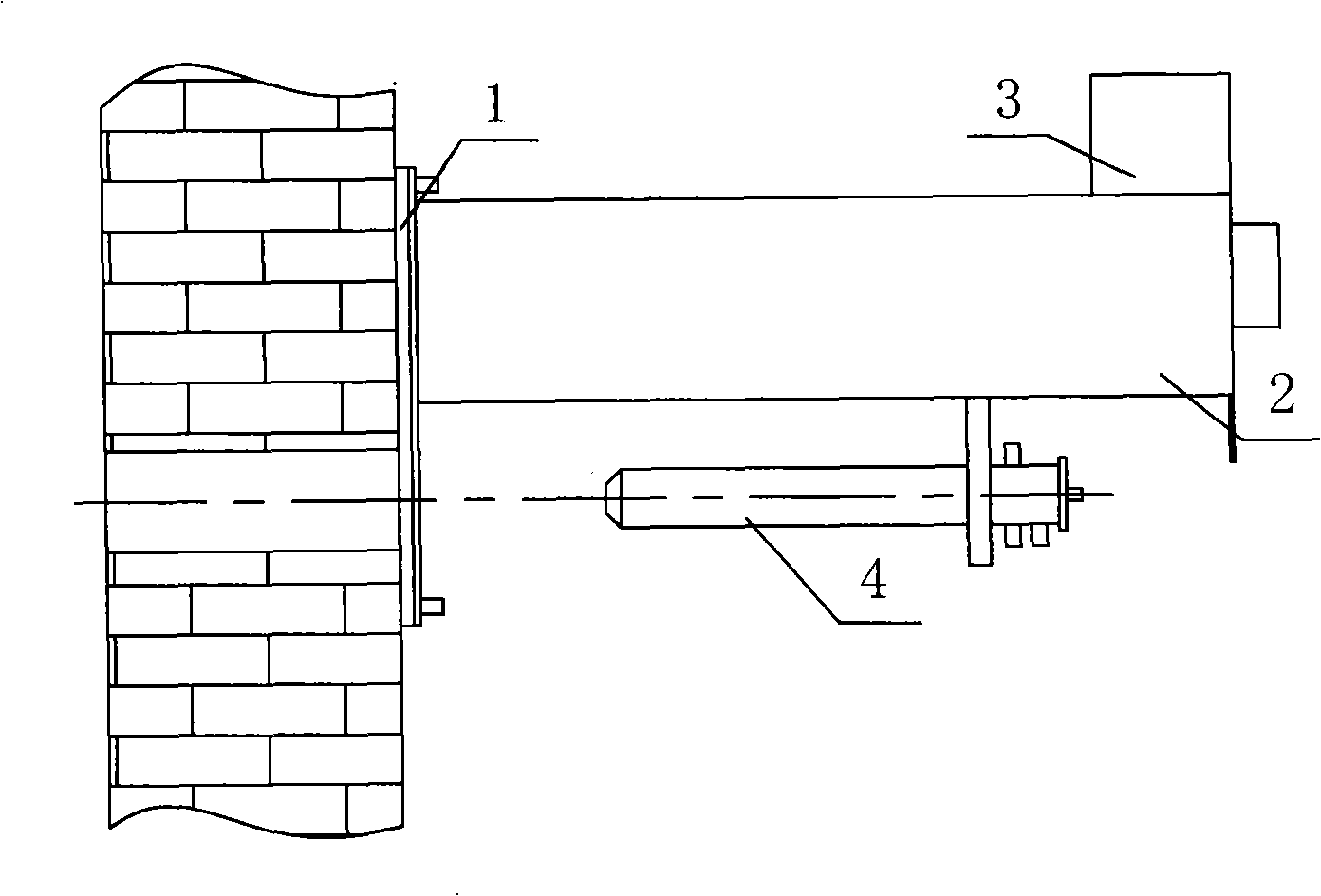

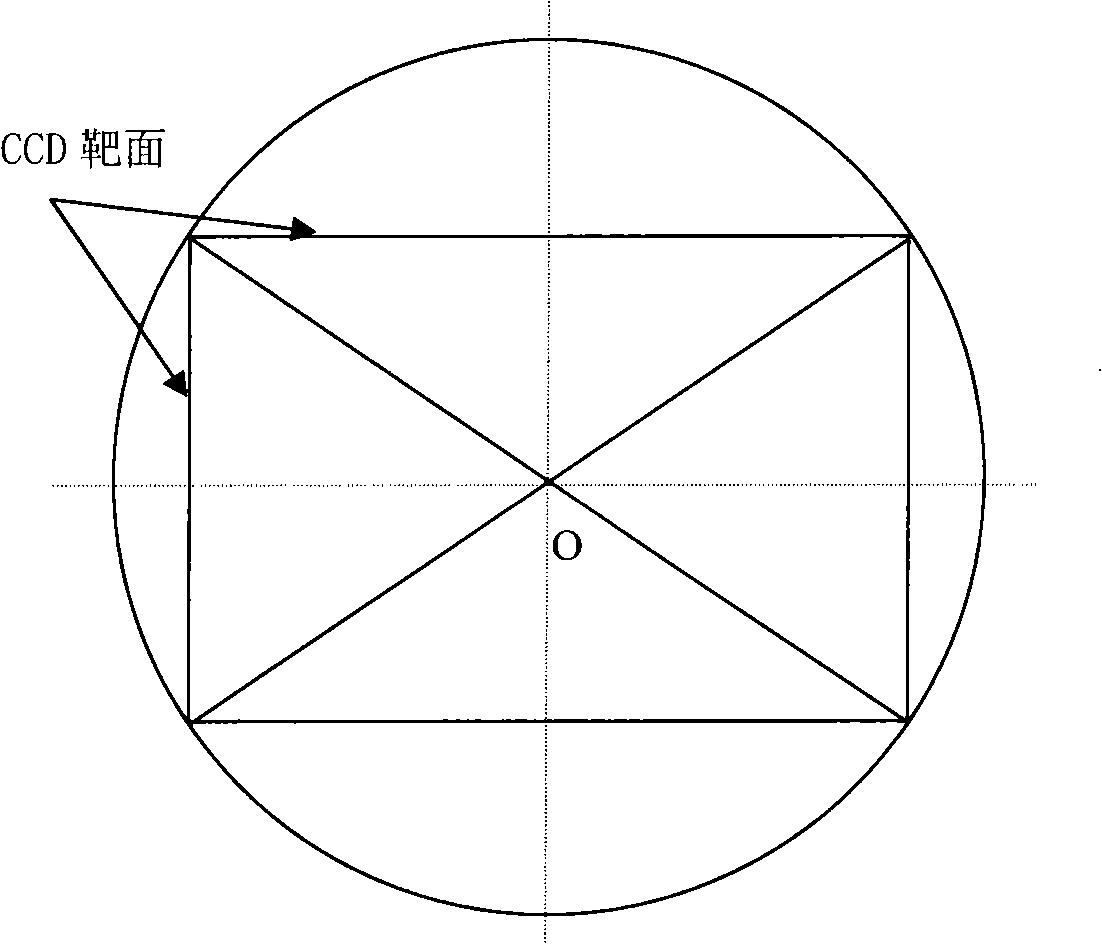

[0021] Refer to figure 1 , 2 , The front end of this system is mainly a high-temperature TV composed of camera devices, transmission devices, protective devices, and control devices. The camera device in the high-temperature TV is a high-temperature probe, and the high-temperature probe penetrates into the high-temperature furnace through a transmission device and a protective device. The image of the object in the high-temperature furnace is imaged by the high-temperature lens through the prefabricated hole (or with the help of the observation hole), and is transmitted to the camera target surface through the mirror tube and converted into an electrical signal, and then transmitted to the control room industrial control host through the coaxial cable . The transmission device is mainly composed of furnace wall protection device, drag mechanism, travel switch, motor and reducer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com