Composite material prick pipe structure wind load simulation test method

A simulation test and composite material technology, applied in the field of simulation test research, to achieve the effects of reliable results, short test period and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

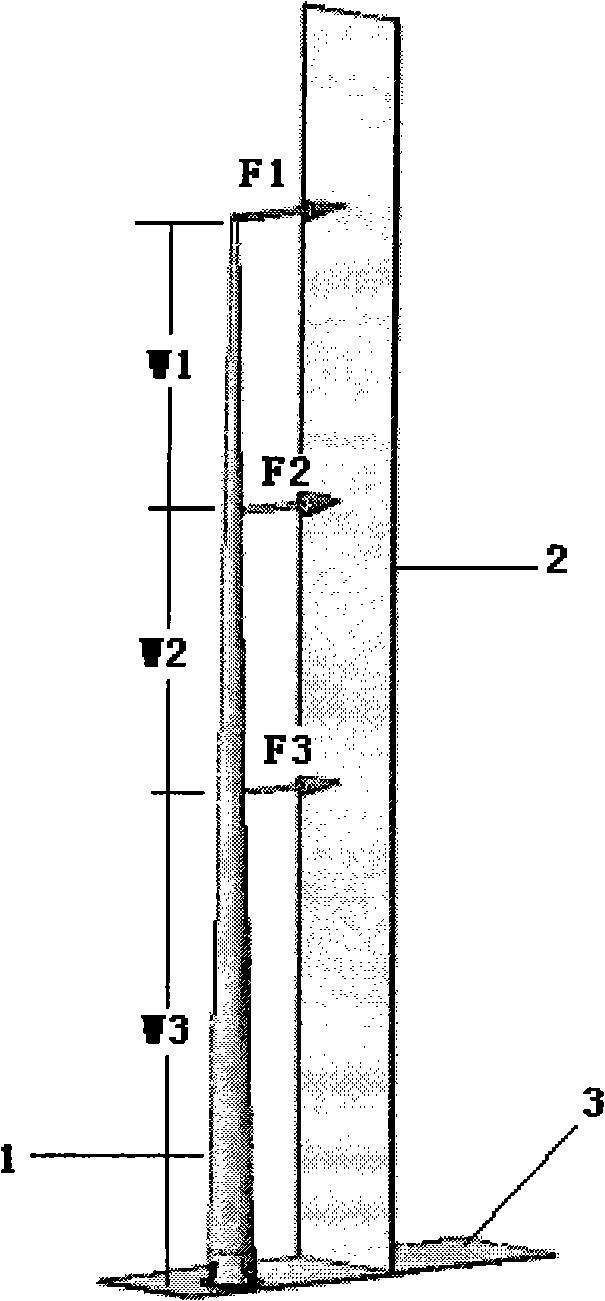

[0025] The deflection test of a utility pole with a composite tapered tube structure, length 8m, top diameter 30mm, bottom diameter 150mm, wind speed 45m / s.

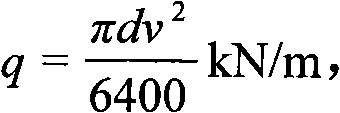

[0026] ① Calculation of the wind load force on the utility pole with tapered tube structure

[0027] The load at the bottom of the pole is q max = π × 0.15 × 45 2 6400 = 0.149 kN / m

[0028] The load on the top of the pole is q min = π × 0.03 × 45 2 6400 = 29.8 N / m .

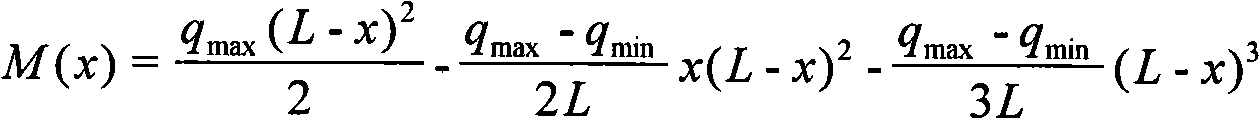

[0029] ② Determination of the loading positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com