Welding connection structure of terminal of electronic device and printed circuit board

A technology for printed circuit boards and electronic devices, which is applied in the field of soldered connection structures, can solve problems such as weakened installation strength, complicated assembly operations, and larger occupied area, and achieve the effect of improving installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

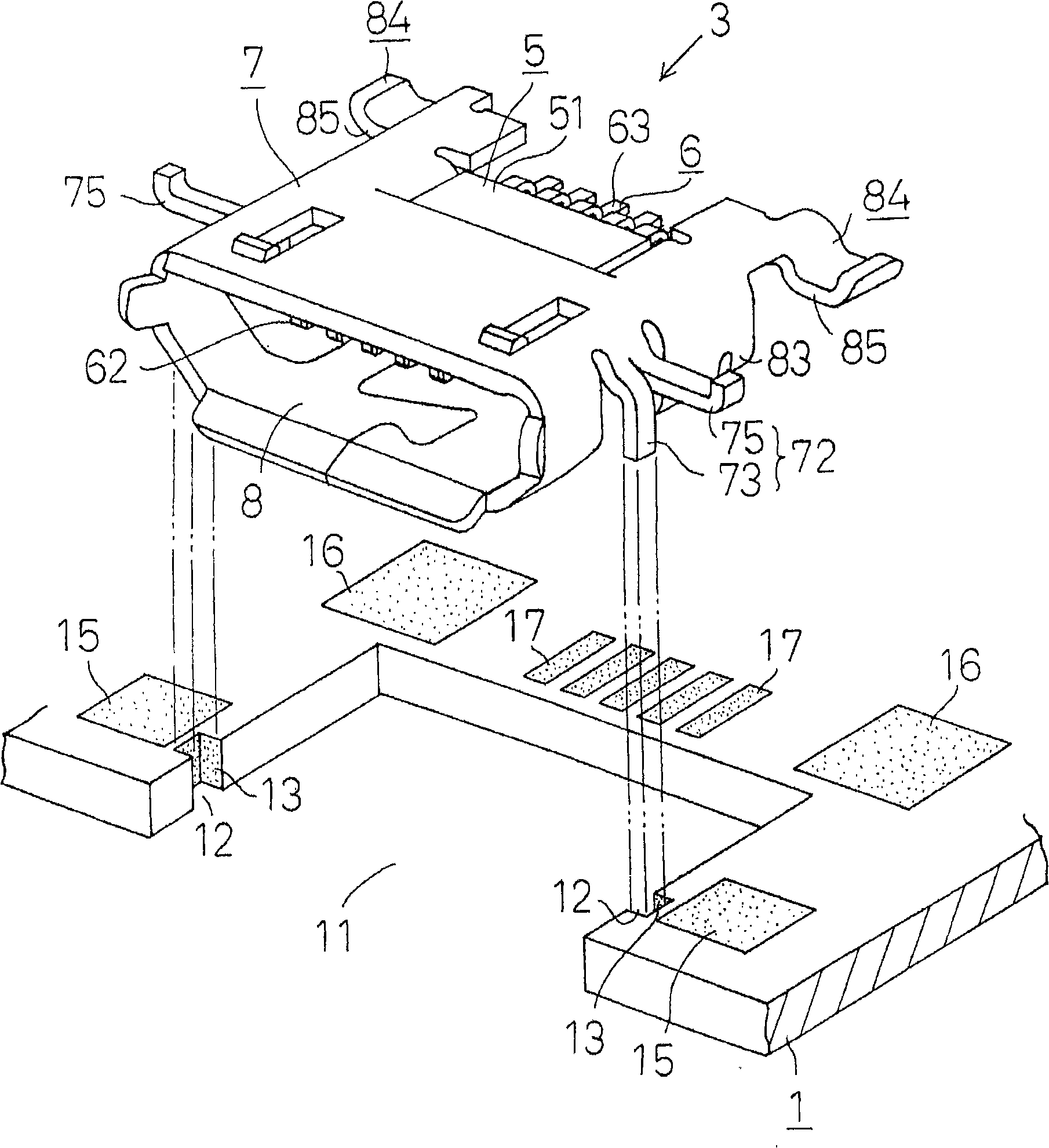

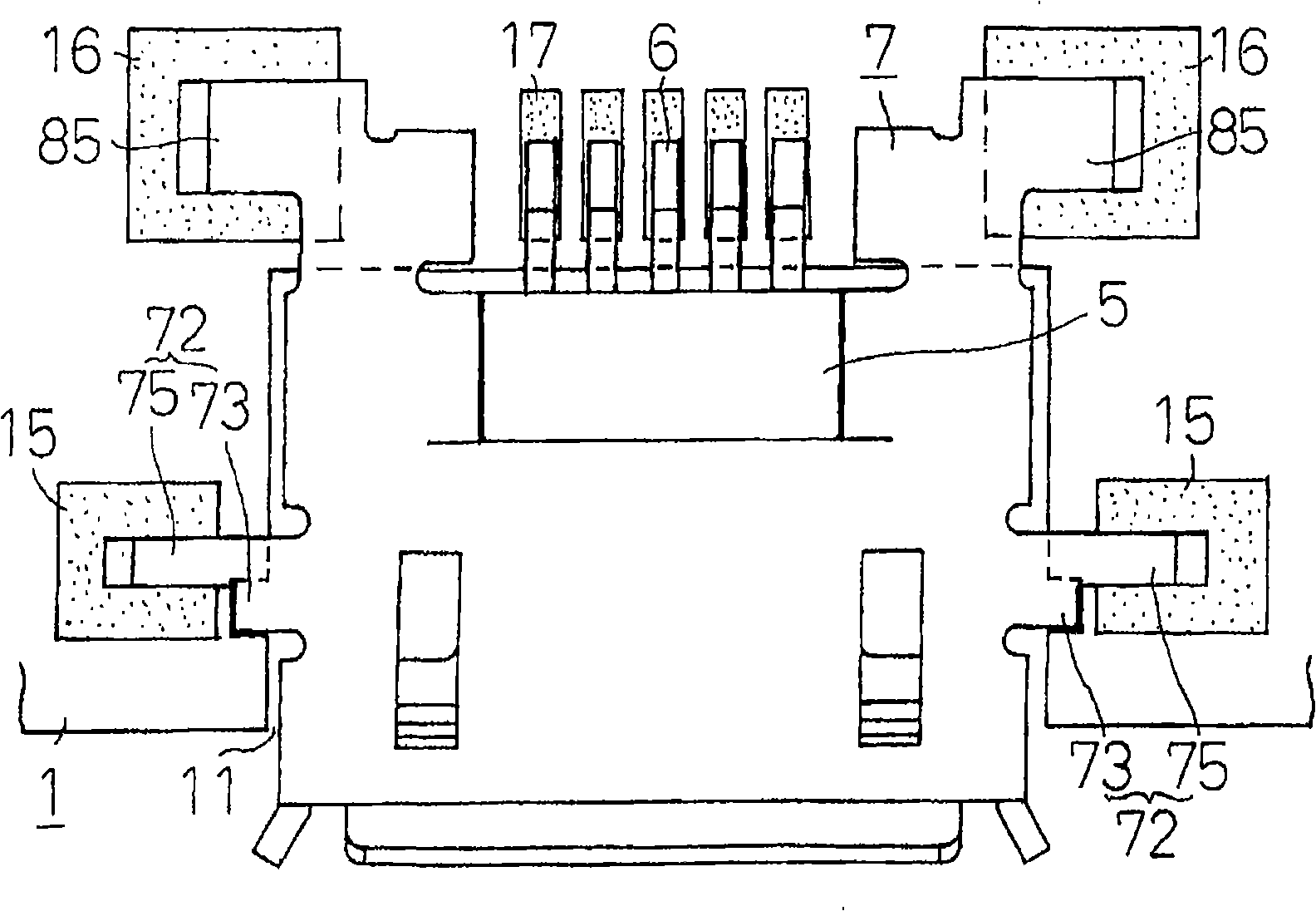

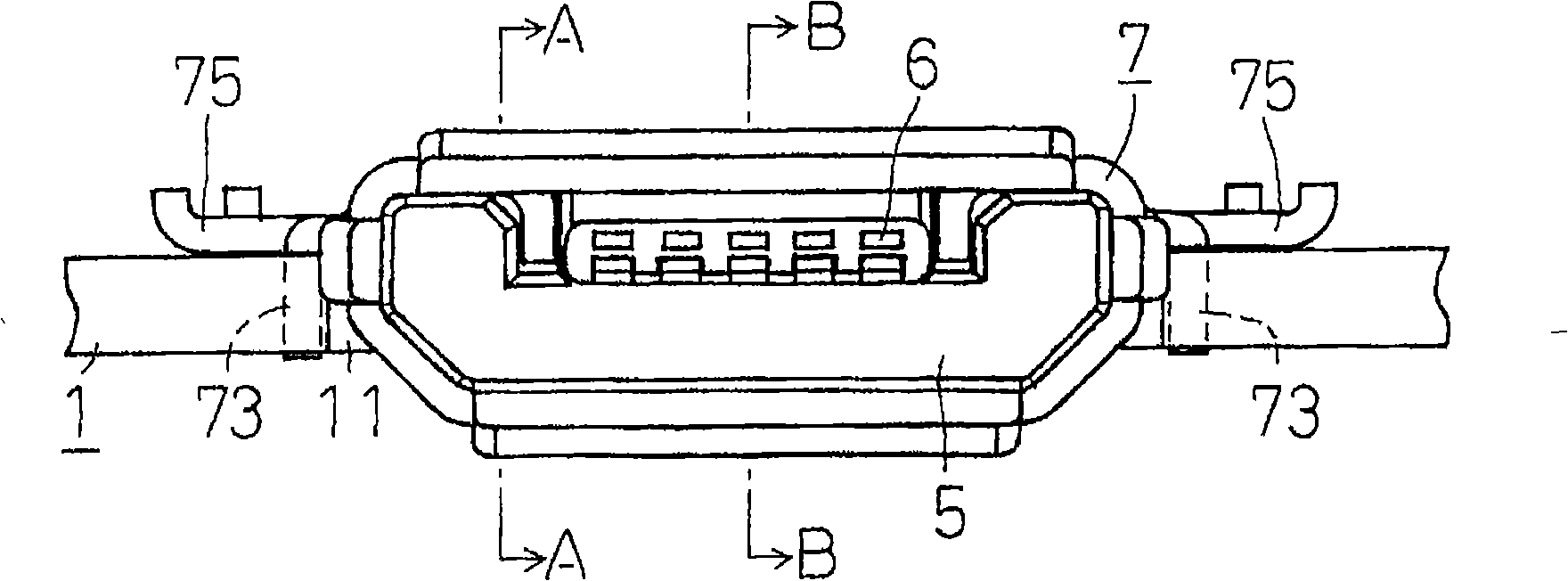

[0045] Figure 1 to Figure 7 It is a figure showing one embodiment of the solder connection structure between the terminal of the electronic device and the printed circuit board of the present invention. In these figures, 1 is a printed circuit board, and 3 is a socket (small USB connector) as an example of an electronic device. one example).

[0046] Formed on the edge of the printed circuit board 1 as figure 1 and figure 2 Shown cutout 11, is formed with small cutout 12,12 in the relative left and right sides of this cutout 11, on the side face of this cutout 12,12, is formed with the first soldering pad (for example by the copper that forms by electroplating) that connects. foil) 13,13.

[0047]Second pads (such as copper foil) 15, 15 for soldering connection are formed on the left and right edges of the slit 11, and a third pad (such as copper foil) for soldering connection is formed on the edge of the back side of the slit 11. 16, 16 and fourth pads (such as copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com