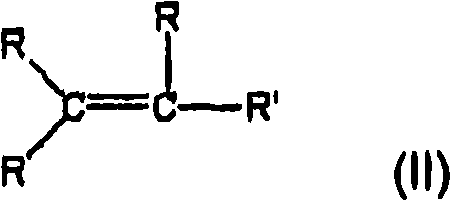

Compositions containing fluorine substituted olefins

A technology of fluoroolefins and compositions, which is applied in the field of compositions containing fluorine-substituted olefins, and can solve the problems of high boiling point, unpleasant, difficult refrigerants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] The coefficient of performance (COP) is a generally accepted measure of refrigerant performance used, inter alia, to represent the relative thermodynamic efficiency of a refrigerant in terms of specific heat or cooling period, including evaporation or condensation of the refrigerant. In refrigeration engineering, the term expresses the ratio of effective refrigeration to the energy expended in compressing water vapor by a compressor. The capacity of the refrigerant represents the cooling or heating value that provides and provides some measure of the capacity of the compressor to pump the heat required to pump a set volume flow of refrigerant. In other words, a higher capacity refrigerant will deliver more cooling or heating capacity for a specific compressor setting. One way to estimate the COP of a refrigerant under specific conditions of use is from the thermodynamic properties of the refrigerant using standard refrigeration cycle analysis techniques (see, eg, R.C. D...

Embodiment 2

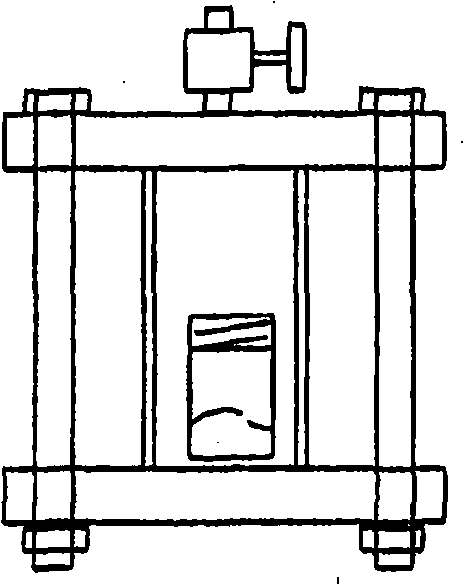

[0164] The compatibility of various refrigeration lubricants with HFO-1225ye and HFO-1234ze was tested. Lubricants tested were mineral oil (C3), alkylbenzene (Zerol 150), ester oil (Mobil EAL 22 cc and Gel 120), polyglycol (PAG) oil (Goodwrench Refrigeration Oil for 134a systems) and poly(α-olefin) oil (CP-6005-100). For each refrigerant / oil combination, three compositions were tested, namely 5, 20 and 50% by weight of lubricant, with the remainder of each being the compound of the invention to be tested.

[0165] The lubricant composition was placed in a thick-walled glass tube. The tube is emptied, the refrigerant compound according to the invention is added and the tube is closed. The tubes were then placed in an air bath environmental chamber where the temperature varied from -50°C to 70°C. The presence of one or more liquid phases was determined by visual inspection of the tube contents at approximately 10°C intervals. When more than one liquid phase was observed, the...

Embodiment 3

[0168] The compatibility of the refrigerant compounds and compositions of the present invention with PAG lubricating oils, when in contact with metals tested for refrigeration and air conditioning systems at 350°C, exhibited better performance than in many refrigeration and air conditioning systems. The conditions found in air conditioning applications are more severe.

[0169] Aluminum, copper and steel sampling tubes are added to thick-walled glass tubes. Two grams of oil were added to the tube. The tube was then emptied and one gram of cryogen was added. Place the tube in an oven at 350°F for one week for visual inspection. The tube was removed at the end of the exposure period.

[0170] Such procedures were used to accomplish the following oil and compound compositions of the invention:

[0171] a) HFC-1234ze and GM Goodwrench PAG oil

[0172] b) HFC-1243zf and GM Goodwrench oil PAG oil

[0173] c) HFC-1234ze and MOPAR-56PAG oils

[0174] d) HFC-1243zf and MOPAR-56P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com